pulse width modulated (PWM) controller for high current

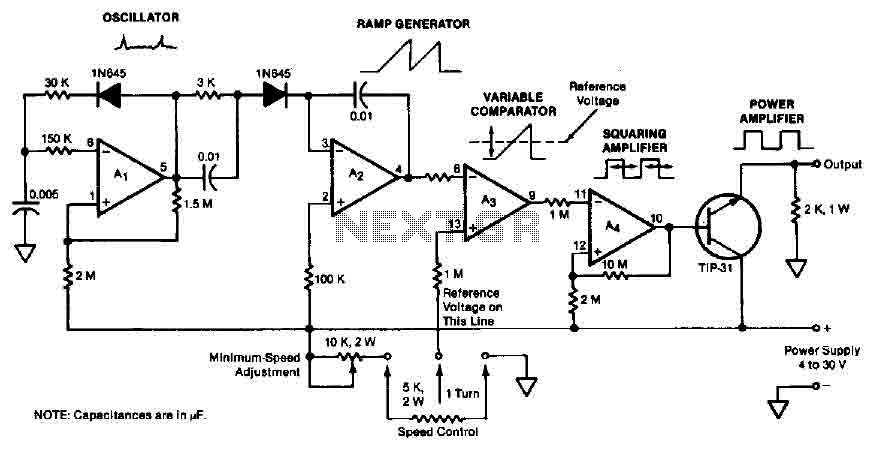

The second 555 timer was configured as a monostable circuit, commonly referred to as a one-shot since an output pulse only occurs if there is a trigger on the input. When this timer is triggered, the potentiometer in the RC timing network allows the output duty cycle to vary, which determines how long each output pulse is high. As the output pulse gets shorter, less current will flow in the motor, causing the motor to slow down. Figures 2 and 3 show a high and low duty cycle pulse for the circuit, respectively, captured on an oscilloscope. The top graph of each figure is the output pulse, while the bottom graph is the input into the monostable timer. If the duty cycle is brought down to zero percent, there will no longer be a high part of each pulse; therefore, no current will flow. The capacitor value was chosen to be 0.039 µF. A minimum RPM of 500 for the motor was desired, so the potentiometer was selected accordingly. The maximum resistance was calculated as 46 k ohms, hence a standard value 50 k precision audio potentiometer was used to ensure that a low RPM could be achieved on the motor. The position of the potentiometer can be adjusted using the rotary-to-linear action of the servo system of the radio. For this design, a linear slide potentiometer was chosen to accommodate this rotary-to-linear action of the servo system. The motor can draw several amps, necessitating a robust transistor to provide current control in the circuit. Based on their current handling capabilities, TIP120 BJT transistors were selected as the output stage to drive the motor. Two TIP120s were wired in parallel to distribute the current load and prevent either transistor from overheating. Additionally, space is limited on the boat; therefore, the transistor had to operate with minimal or no heatsinking. After testing revealed that the transistors were drawing too much current directly from the monostable 555 timer output, leading to premature failures, an additional TIP120 was incorporated in a cascade arrangement with the output transistors to provide a larger gain. The output of the 555 timer has a maximum current output of 200 mA, and it was shown that an overcurrent condition could occur, based on a startup current of 20 amps and a typical gain of approximately 100. If the gain is 100 and the motor requires 20 amps, the 555 timer would need to supply about 200 mA, which is near its maximum output and could cause it to overheat and fail. By saturating the first stage of the cascade with the output from the monostable 555 timer and connecting the emitter of the first transistor to the bases of the output transistors, the gain on the output stage was increased by approximately 100, reducing the current demand from the timer to 2 mA. The operating voltage for the system is 7.2 volts, as this is the voltage of the motor battery pack. The 555 timers can operate within a voltage range of +5 to +18 volts, allowing the battery pack to power the speed controller without requiring voltage regulation. The circuit schematic is illustrated in Figure 3 as designed and built. The circuit functions correctly as intended, although the speed-controlling potentiometer exhibits slight nonlinearity. The output pulse drops low, and the transistors turn off completely when the slide is fully down, preventing the motor from drawing current when idle. However, the upper end of the slide does not increase the speed beyond a certain threshold. Despite this limitation, the controller operates effectively for the specified design and motor.

The circuit utilizes a 555 timer configured in monostable mode, which generates a single output pulse in response to a trigger signal. The pulse duration is controlled by an RC timing network comprising a resistor (the potentiometer) and a capacitor (0.039 µF). The duty cycle can be adjusted by varying the resistance of the potentiometer, which alters the duration of the output pulse. A lower duty cycle results in shorter output pulses, thereby reducing the average voltage supplied to the motor and consequently slowing it down. The use of two TIP120 transistors in parallel enhances the current handling capacity, allowing for efficient motor control while minimizing the risk of overheating. The cascade configuration of the TIP120s amplifies the current capability further, ensuring that the 555 timer operates within safe limits. The choice of a linear slide potentiometer allows for intuitive control of motor speed, translating the rotary motion of the servo into a linear adjustment for precise speed regulation. The overall design is compact, suitable for limited space applications such as on a boat, and effectively meets the operational requirements of the motor control system.The second 555 timer was configured as a monostable circuit, commonly referred to as a one shot since an output pulse only occurs if there is a trigger on the input. When this timer is triggered, the potentiometer in the RC timing network allows the output duty cycle to vary, which determines how long each output pulse is high.

As the output high pulse gets shorter, less current will flow in the motor causing the motor to slow down. Figures 2 and 3 show a high and low duty cycle pulse for the circuit, respectively, captured on an oscilloscope. The top graph of each figure is the output pulse, while the bottom graph is the input into the monostable timer.

If the duty cycle is brought down to zero percent, there will no longer be a high part of each pulse, therefore no current will flow. The capacitor value was chosen to be 0. 039uF. I wanted a minimum RPM of 500 for the motor, so the potentiometer was chosen accordingly. Equation 3 shows how the value of the potentiometer was chosen. The maximum resistance was calculated as 46k ohms, therefore, I used a standard value 50k precision audio potentiometer.

This would assure that I could achieve a low RPM on the motor. Position of the potentiometer can be adjusted using the rotary to linear action of the servo system of the radio. For this design, a linear slide potentiometer was chosen to accommodate this rotary to linear action of the servo system.

As mentioned, the motor can draw several amps, requiring a robust transistor to provide the current control in the circuit. Based on their current handling capabilities, TIP120 BJT transistors were chosen as the output stage to drive the motor.

Two TIP120 ’s were wired in parallel to distribute the current load and keep either transistor from running too hot. Also, space is at a premium on the boat, therefore the transistor had to operate with little or no heatsinking.

After testing showed that the transistors were pulling too much current directly from the monostable 555 timer output and causing premature failures, an additional TIP120 was incorporated in a cascade arrangement with the output transistors to produce a larger gain. The output of the 555 timer has a maximum current output of 200 mA and Equation 4 shows how there could be an overcurrent condition, based on a start up current of 20 amps and a typical gain of approximately 100.

If the gain is 100 and the motor requires 20 amps, the 555 timer would have to supply about 200 mA, demanding nearly the maximum current from the timer and causing it to overheat and burn up. By saturating the first stage of the cascade with the output from the monostable 555 timer and running the emitter of the first transistor into the bases of the output transistors, the gain on the output stage was increased by approximately 100, lowering the current demand of the timer to 2 mA.

The operating voltage for the system is 7. 2 volts. This voltage was chosen because this is the voltage of the motor battery pack. The 555 timers can run on +5 to +18 volts so the battery pack can be used to run the speed controller as well with no voltage regulation. The circuit schematic is shown below in Figure 3 as designed and built. The circuit is working correctly, the way it was designed, but the speed controlling potentiometer is slightly nonlinear.

The output pulse falls low and the transistors turn off completely when the slide is all the way down so the motor will not draw current when idle. However, the very top end of the slide does not increase the speed past a certain point. For this design and motor, though, the controller works fine. 🔗 External reference

The circuit utilizes a 555 timer configured in monostable mode, which generates a single output pulse in response to a trigger signal. The pulse duration is controlled by an RC timing network comprising a resistor (the potentiometer) and a capacitor (0.039 µF). The duty cycle can be adjusted by varying the resistance of the potentiometer, which alters the duration of the output pulse. A lower duty cycle results in shorter output pulses, thereby reducing the average voltage supplied to the motor and consequently slowing it down. The use of two TIP120 transistors in parallel enhances the current handling capacity, allowing for efficient motor control while minimizing the risk of overheating. The cascade configuration of the TIP120s amplifies the current capability further, ensuring that the 555 timer operates within safe limits. The choice of a linear slide potentiometer allows for intuitive control of motor speed, translating the rotary motion of the servo into a linear adjustment for precise speed regulation. The overall design is compact, suitable for limited space applications such as on a boat, and effectively meets the operational requirements of the motor control system.The second 555 timer was configured as a monostable circuit, commonly referred to as a one shot since an output pulse only occurs if there is a trigger on the input. When this timer is triggered, the potentiometer in the RC timing network allows the output duty cycle to vary, which determines how long each output pulse is high.

As the output high pulse gets shorter, less current will flow in the motor causing the motor to slow down. Figures 2 and 3 show a high and low duty cycle pulse for the circuit, respectively, captured on an oscilloscope. The top graph of each figure is the output pulse, while the bottom graph is the input into the monostable timer.

If the duty cycle is brought down to zero percent, there will no longer be a high part of each pulse, therefore no current will flow. The capacitor value was chosen to be 0. 039uF. I wanted a minimum RPM of 500 for the motor, so the potentiometer was chosen accordingly. Equation 3 shows how the value of the potentiometer was chosen. The maximum resistance was calculated as 46k ohms, therefore, I used a standard value 50k precision audio potentiometer.

This would assure that I could achieve a low RPM on the motor. Position of the potentiometer can be adjusted using the rotary to linear action of the servo system of the radio. For this design, a linear slide potentiometer was chosen to accommodate this rotary to linear action of the servo system.

As mentioned, the motor can draw several amps, requiring a robust transistor to provide the current control in the circuit. Based on their current handling capabilities, TIP120 BJT transistors were chosen as the output stage to drive the motor.

Two TIP120 ’s were wired in parallel to distribute the current load and keep either transistor from running too hot. Also, space is at a premium on the boat, therefore the transistor had to operate with little or no heatsinking.

After testing showed that the transistors were pulling too much current directly from the monostable 555 timer output and causing premature failures, an additional TIP120 was incorporated in a cascade arrangement with the output transistors to produce a larger gain. The output of the 555 timer has a maximum current output of 200 mA and Equation 4 shows how there could be an overcurrent condition, based on a start up current of 20 amps and a typical gain of approximately 100.

If the gain is 100 and the motor requires 20 amps, the 555 timer would have to supply about 200 mA, demanding nearly the maximum current from the timer and causing it to overheat and burn up. By saturating the first stage of the cascade with the output from the monostable 555 timer and running the emitter of the first transistor into the bases of the output transistors, the gain on the output stage was increased by approximately 100, lowering the current demand of the timer to 2 mA.

The operating voltage for the system is 7. 2 volts. This voltage was chosen because this is the voltage of the motor battery pack. The 555 timers can run on +5 to +18 volts so the battery pack can be used to run the speed controller as well with no voltage regulation. The circuit schematic is shown below in Figure 3 as designed and built. The circuit is working correctly, the way it was designed, but the speed controlling potentiometer is slightly nonlinear.

The output pulse falls low and the transistors turn off completely when the slide is all the way down so the motor will not draw current when idle. However, the very top end of the slide does not increase the speed past a certain point. For this design and motor, though, the controller works fine. 🔗 External reference