RGB LED experiment Arduino

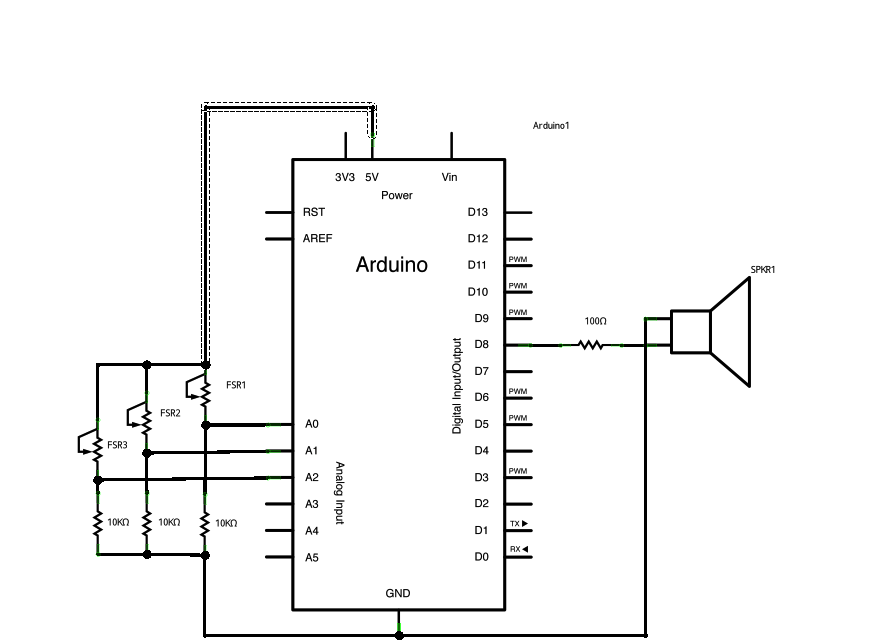

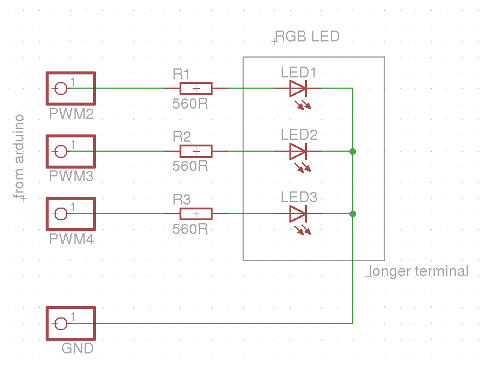

This evening, after returning home from a paragliding appointment, there was a realization that the RGB LED driver code written the previous day needed improvement. The code was refined and annotated extensively for educational purposes. Although the current skill level exceeds this project, it remains enjoyable to experiment with. An RGB LED comprises three individual LEDs in one package: red, green, and blue, which is the origin of the acronym. If RGB LEDs are unavailable, individual red, green, and blue LEDs can be used instead. For optimal results, the visible brightness of the LEDs should be similar. The concept involves mixing the three primary colors (red, green, blue) to create a variety of colors, albeit not all possible colors. This mixing is achieved through three individual PWM signals generated by an AVR controller on an Arduino board. Additional information on PWM can be found in relevant resources. The project is straightforward yet visually appealing, allowing for experimentation with different waveform generation. Users are encouraged to modify the code to utilize a harmonic (sine) function for light intensity. Advanced users may avoid the built-in sin() function and create sinusoidal output using arrays. The video accompanying this project may not capture the subtle color changes of the LED due to limitations of the phone’s camera, but the visual effect is significantly better in person, encouraging construction of the project. The other side of the breadboard and additional components are allocated for another project and are not currently connected. To set up the RGB LED, connect it to the Arduino board in series with three 560-ohm resistors, as illustrated in the accompanying figure (200-ohm resistors are also acceptable). These resistors limit the current flowing through the LEDs, which should not exceed 50mA each to prevent damage to both the microcontroller and the LEDs. If using individual red, green, and blue LEDs, this is also acceptable. A suggestion is to place the RGB LED or the three individual LEDs in a thin paper tube, as shown in the video, to diffuse and mix the light, resulting in a softer output. The concept of pass-by-reference may be challenging to grasp; however, in microcontroller systems where memory is often limited, it becomes crucial for efficiency. Furthermore, understanding HSL-to-RGB conversion is important, as HSL (hue-saturation-lightness) provides a more intuitive color description, though RGB is necessary for output due to the LED configuration.

An RGB LED driver circuit utilizes a microcontroller, such as an AVR or Arduino, to control the brightness of red, green, and blue LEDs through PWM (Pulse Width Modulation) signals. The circuit typically consists of the RGB LED connected in series with current-limiting resistors to protect the LEDs and the microcontroller. The resistors are calculated based on the forward voltage of the LEDs and the desired current, typically around 20mA for standard brightness.

The microcontroller's PWM outputs are configured to control each color channel independently, allowing for the mixing of colors by adjusting the duty cycle of each PWM signal. The duty cycle determines the proportion of time the LED is turned on versus off, effectively controlling the perceived brightness.

For color mixing, the user can program the microcontroller to generate various color combinations by varying the PWM signals. This can be enhanced by implementing algorithms for HSL-to-RGB conversion, enabling a more intuitive way to select colors based on hue, saturation, and lightness. The conversion process involves calculating the RGB values from the desired HSL values, which requires understanding the relationships between the color components.

In terms of physical setup, it is advisable to use a breadboard for prototyping, allowing for easy adjustments and modifications. The suggestion to use a paper tube for light diffusion is practical, as it helps to create a more uniform light output and can enhance the visual effect of the color mixing.

Overall, this RGB LED driver project serves as an excellent educational tool, demonstrating fundamental concepts in electronics, programming, and color theory while providing a platform for experimentation and creativity.This evening as I came home from a paragliding appointment, I had a feeling that I must improve my yesterday-written RGB LED driver code. So I cleaned it up a bit, and wrote a lot of comments to make it more useful for educational purposes.

I`m alredy over this level, but it`s fun to play with it. An RGB LED is just three LEDs in a single package: red, green and blue, from here comes the TLA. If you have no RGB LEDs currently, you can replace it with a red, a green and a blue LED. For a good result, the LEDs` (visible) brightnesses have to be similar. The idea is, that from the three basic colors (r, g, b) a lot of colors (but not all) can be mixed. This mixing is performed by three individual PWM signal applied by the AVR controller on the Arduino board.

See more about PWM at. I think the whole thing is very simple, but it looks nice, and you can experiment with the generation of different waveforms. Try to modify the code to use a harmonic (sine) function as input for the lightness. For more advanced users: avoid the built-in sin() function, but produce sinusoidal output. Hint: arrays This video may not be as exciting as the previous one (see here ) because my phone`s camera is unable to capture the fine changes in the color of the LED.

It seems much more better in reality, so you really must build one. The other side of the breadboard (and the rest of the parts)is used in another project and it`s not connected to the board now. I was just too lazy to disassemble it. This doesn`t need explanation. Just connect your RGB LED to the Arduino board in series with three 560 © resistors as you can see on the figure above.

(200 © is fine too these resistors define the current which flows through the LEDs. The current cannot exceed 50mA (each), as it could damage the microcontroller and the LED too. ) If you have individual LEDs for red, green and blue, it`s fine too. Tip: put the RGB LED or the three individual LEDs in a thin paper tube as it can be seen on my video. It diffuses and mixes the light and it becomes less direct. Well, the pass-by-reference can be a bit difficult to understand, but when every byte of the memory worth a lot because of the limited space, which can happen often especially in microcontroller systems it`s very important.

And it speeds things up too. Read more at The interesting part is the HSL-to-RGB conversion. HSL means hue-saturation-lightness and it`s a more natural description of colors than the RGB. However, RGB must be applied to the outputs since we only have red, green and blue LEDs. And that`s why you need to convert. 🔗 External reference

An RGB LED driver circuit utilizes a microcontroller, such as an AVR or Arduino, to control the brightness of red, green, and blue LEDs through PWM (Pulse Width Modulation) signals. The circuit typically consists of the RGB LED connected in series with current-limiting resistors to protect the LEDs and the microcontroller. The resistors are calculated based on the forward voltage of the LEDs and the desired current, typically around 20mA for standard brightness.

The microcontroller's PWM outputs are configured to control each color channel independently, allowing for the mixing of colors by adjusting the duty cycle of each PWM signal. The duty cycle determines the proportion of time the LED is turned on versus off, effectively controlling the perceived brightness.

For color mixing, the user can program the microcontroller to generate various color combinations by varying the PWM signals. This can be enhanced by implementing algorithms for HSL-to-RGB conversion, enabling a more intuitive way to select colors based on hue, saturation, and lightness. The conversion process involves calculating the RGB values from the desired HSL values, which requires understanding the relationships between the color components.

In terms of physical setup, it is advisable to use a breadboard for prototyping, allowing for easy adjustments and modifications. The suggestion to use a paper tube for light diffusion is practical, as it helps to create a more uniform light output and can enhance the visual effect of the color mixing.

Overall, this RGB LED driver project serves as an excellent educational tool, demonstrating fundamental concepts in electronics, programming, and color theory while providing a platform for experimentation and creativity.This evening as I came home from a paragliding appointment, I had a feeling that I must improve my yesterday-written RGB LED driver code. So I cleaned it up a bit, and wrote a lot of comments to make it more useful for educational purposes.

I`m alredy over this level, but it`s fun to play with it. An RGB LED is just three LEDs in a single package: red, green and blue, from here comes the TLA. If you have no RGB LEDs currently, you can replace it with a red, a green and a blue LED. For a good result, the LEDs` (visible) brightnesses have to be similar. The idea is, that from the three basic colors (r, g, b) a lot of colors (but not all) can be mixed. This mixing is performed by three individual PWM signal applied by the AVR controller on the Arduino board.

See more about PWM at. I think the whole thing is very simple, but it looks nice, and you can experiment with the generation of different waveforms. Try to modify the code to use a harmonic (sine) function as input for the lightness. For more advanced users: avoid the built-in sin() function, but produce sinusoidal output. Hint: arrays This video may not be as exciting as the previous one (see here ) because my phone`s camera is unable to capture the fine changes in the color of the LED.

It seems much more better in reality, so you really must build one. The other side of the breadboard (and the rest of the parts)is used in another project and it`s not connected to the board now. I was just too lazy to disassemble it. This doesn`t need explanation. Just connect your RGB LED to the Arduino board in series with three 560 © resistors as you can see on the figure above.

(200 © is fine too these resistors define the current which flows through the LEDs. The current cannot exceed 50mA (each), as it could damage the microcontroller and the LED too. ) If you have individual LEDs for red, green and blue, it`s fine too. Tip: put the RGB LED or the three individual LEDs in a thin paper tube as it can be seen on my video. It diffuses and mixes the light and it becomes less direct. Well, the pass-by-reference can be a bit difficult to understand, but when every byte of the memory worth a lot because of the limited space, which can happen often especially in microcontroller systems it`s very important.

And it speeds things up too. Read more at The interesting part is the HSL-to-RGB conversion. HSL means hue-saturation-lightness and it`s a more natural description of colors than the RGB. However, RGB must be applied to the outputs since we only have red, green and blue LEDs. And that`s why you need to convert. 🔗 External reference