schematics Control speed of Nidec fan

A Nidec TA450DC B35502-35 fan has been installed in a large wooden cabinet housing a computer and other electronics, which generates significant heat. The fan is designed to draw air from the room and exhaust it through openings at the top of the cabinet. The fan features four wires: red (+12V), black (ground), blue, and yellow. Currently, only the red and black wires are used to power the fan at full speed, resulting in excessive noise. A toggle switch is used to turn the fan on and off. The objective is to replace the toggle switch with a variable speed control knob, allowing the fan speed to be adjusted. The minimum setting should provide just enough power for the fan to operate at its lowest speed, while the maximum setting should enable full speed operation. The user seeks guidance on the appropriate type of knob, wiring, and whether to utilize the additional blue and yellow wires for speed control, or to adjust the voltage instead.

To achieve variable speed control for the Nidec TA450DC fan, a pulse-width modulation (PWM) controller can be employed. This method allows for effective speed regulation while maintaining low noise levels. The fan operates on a 12V DC supply, and the red wire is connected to the positive terminal, while the black wire connects to ground. The blue and yellow wires typically serve as a tachometer output and a PWM control input, respectively.

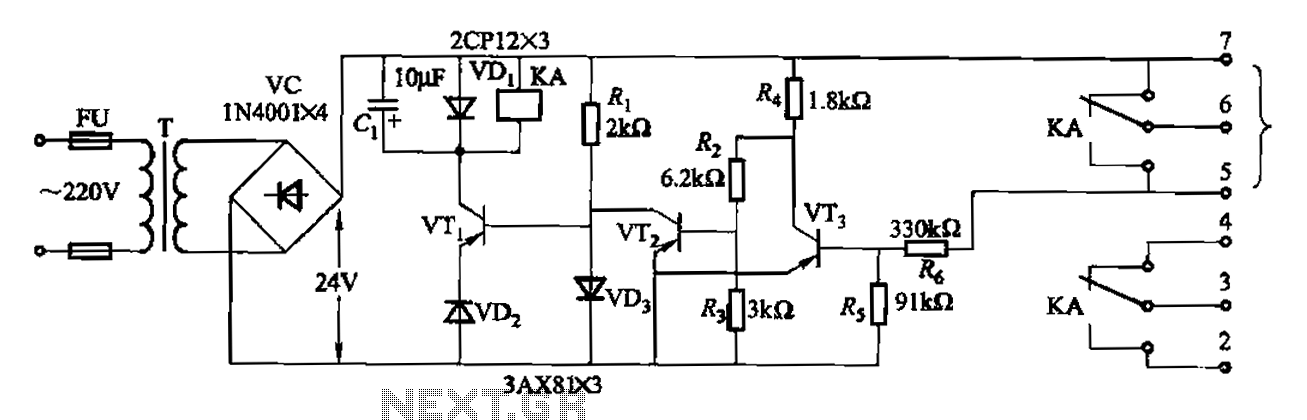

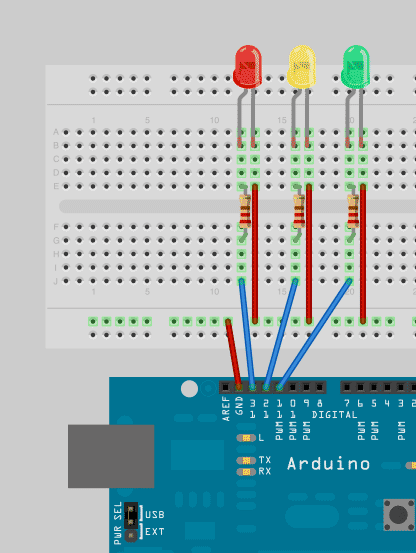

A suitable approach involves using a PWM speed controller circuit, which can be constructed using a transistor or a dedicated PWM controller IC. The PWM signal modulates the voltage supplied to the fan, effectively controlling its speed. The circuit can be designed with a potentiometer (variable resistor) that acts as the speed control knob. The potentiometer is connected in such a way that it adjusts the duty cycle of the PWM signal based on its position.

The wiring configuration would include connecting the potentiometer to the control input (yellow wire) of the fan. The PWM circuit's output will be fed into the yellow wire, while the blue wire can be left unconnected if it is solely for tachometer feedback, which may not be necessary for basic speed control.

For assembly, a small circuit board can be used to house the components. The PWM circuit will require a power source, which can be derived from the same 12V supply used to power the fan. The transistor or PWM controller IC can be mounted on the board, with the potentiometer accessible from the exterior for user adjustment.

In summary, the desired outcome is to create a simple yet effective PWM speed control circuit that utilizes a potentiometer to adjust the fan speed smoothly from minimum to maximum, while ensuring that the fan operates quietly and efficiently within the wooden cabinet.I have a Nidec TA450DC B35502-35 fan which I`ve installed in a large wooden cabinet where my computer and other electronics sit. This cabinet of course gets hot from all the electronics inside of it. The fan forces air in from the room and goes out through openings in the top of the cabinet. This fan has 4 wires: red (+12v), black (ground), and then blue and yellow. I`m using only red and black to give the fan full 12v power. The problem is since it`s at max speed, it is way too loud. I have a simple toggle switch to turn it on and off. What I would like to do is replace the toggle switch with a knob to adjust the speed. I don`t know how to use the other two wires to control the speed. What kind of knob do I need to get, and how should I wire it The minimum setting of the knob should feed the fan with its minimum required power to spin at the lowest speed possible, and the highest setting should spin it at full possible speed. I don`t have any problem with soldering a small circuit board together for this project, I just have no idea what schematic I need to put together.

I`ve played with electronics and their components all my life but don`t know nearly enough to even begin understanding how to accomplish this. It should be simple, right Should I be using one or both of the additional wires for this, or should I use some method of adjusting the voltage

🔗 External reference

To achieve variable speed control for the Nidec TA450DC fan, a pulse-width modulation (PWM) controller can be employed. This method allows for effective speed regulation while maintaining low noise levels. The fan operates on a 12V DC supply, and the red wire is connected to the positive terminal, while the black wire connects to ground. The blue and yellow wires typically serve as a tachometer output and a PWM control input, respectively.

A suitable approach involves using a PWM speed controller circuit, which can be constructed using a transistor or a dedicated PWM controller IC. The PWM signal modulates the voltage supplied to the fan, effectively controlling its speed. The circuit can be designed with a potentiometer (variable resistor) that acts as the speed control knob. The potentiometer is connected in such a way that it adjusts the duty cycle of the PWM signal based on its position.

The wiring configuration would include connecting the potentiometer to the control input (yellow wire) of the fan. The PWM circuit's output will be fed into the yellow wire, while the blue wire can be left unconnected if it is solely for tachometer feedback, which may not be necessary for basic speed control.

For assembly, a small circuit board can be used to house the components. The PWM circuit will require a power source, which can be derived from the same 12V supply used to power the fan. The transistor or PWM controller IC can be mounted on the board, with the potentiometer accessible from the exterior for user adjustment.

In summary, the desired outcome is to create a simple yet effective PWM speed control circuit that utilizes a potentiometer to adjust the fan speed smoothly from minimum to maximum, while ensuring that the fan operates quietly and efficiently within the wooden cabinet.I have a Nidec TA450DC B35502-35 fan which I`ve installed in a large wooden cabinet where my computer and other electronics sit. This cabinet of course gets hot from all the electronics inside of it. The fan forces air in from the room and goes out through openings in the top of the cabinet. This fan has 4 wires: red (+12v), black (ground), and then blue and yellow. I`m using only red and black to give the fan full 12v power. The problem is since it`s at max speed, it is way too loud. I have a simple toggle switch to turn it on and off. What I would like to do is replace the toggle switch with a knob to adjust the speed. I don`t know how to use the other two wires to control the speed. What kind of knob do I need to get, and how should I wire it The minimum setting of the knob should feed the fan with its minimum required power to spin at the lowest speed possible, and the highest setting should spin it at full possible speed. I don`t have any problem with soldering a small circuit board together for this project, I just have no idea what schematic I need to put together.

I`ve played with electronics and their components all my life but don`t know nearly enough to even begin understanding how to accomplish this. It should be simple, right Should I be using one or both of the additional wires for this, or should I use some method of adjusting the voltage

🔗 External reference