Soldering Iron Tip Preserver

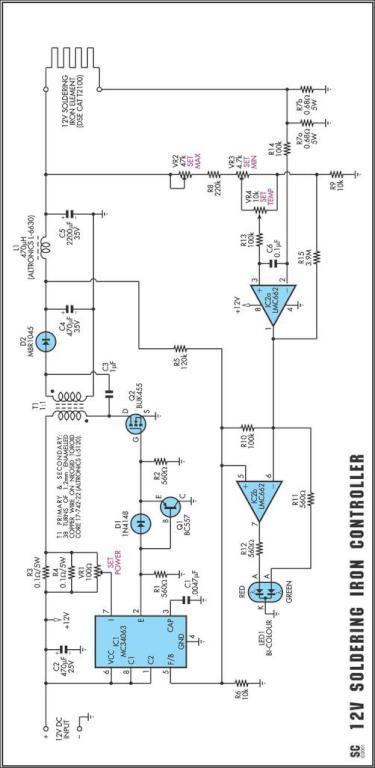

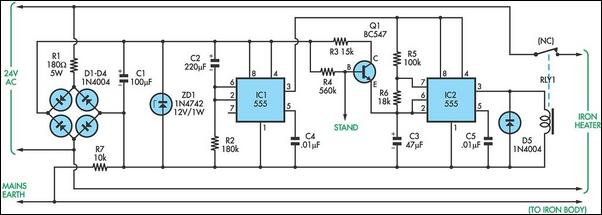

Although 60/40 solder melts at approximately 200°C, the tip temperature of a soldering iron should be maintained at around 370°C. This high temperature is essential for creating a good, quick joint without risking damage to delicate components, as prolonged contact with the iron can lead to overheating. However, at this temperature, the soldering iron tip oxidizes quickly and requires constant cleaning. This circuit addresses that issue by keeping the soldering tip temperature just below 200°C while the iron is at rest, significantly reducing oxidation. The iron can be quickly heated back to soldering temperature in just a few seconds when necessary. Normal soldering operations, where the iron is returned to rest for short periods, remain unaffected due to the thermal inertia of the iron. The circuit is centered around two 555 timers (IC1 & IC2). IC1 is configured as a monostable timer, providing an initial warm-up period of approximately 45 seconds to heat the iron. After this period, its pin 3 output goes high, activating IC2, which is set up in an astable configuration. IC2 controls the power to the iron via relay RLY1, maintaining the standby temperature by switching the iron on for about one second every six seconds. The presence of the iron in its stand is detected through electrical contact, and minor modifications to the stand may be required for proper operation. When the iron is at rest, the base of transistor Q1 is pulled low, turning it off. Conversely, when the iron is removed from the stand, Q1 turns on, pulling pins 2 and 6 of IC2 high to inhibit its operation. During this period, pin 3 of IC2 remains low, allowing continuous power to the iron through the normally closed (NC) contacts of relay RLY1. It is important to note that the specific soldering iron for which this circuit was designed operates with its own 24V supply transformer; other soldering irons may necessitate different power supply configurations. The warm-up time and standby temperature can be adjusted by changing the values of resistors R2 and R5 as needed.

This circuit utilizes two 555 timer ICs to manage the heating and standby operation of a soldering iron effectively. The first timer (IC1) is configured in monostable mode, which allows it to trigger a warm-up sequence for the soldering iron. Upon activation, IC1 provides a high output for a predetermined duration, ensuring that the soldering iron reaches its optimal operating temperature efficiently. The second timer (IC2), configured in astable mode, takes over once the warm-up period is completed. IC2 generates a pulse width modulation (PWM) signal that controls relay RLY1, which in turn regulates the power supplied to the soldering iron.

The relay acts as a switch that connects or disconnects the power to the soldering iron based on the output from IC2. The PWM control helps maintain the soldering iron at a lower standby temperature, reducing oxidation and prolonging the life of the soldering tip. The detection mechanism for the soldering iron's presence is critical; it relies on a simple electrical contact that indicates when the iron is placed back in its stand. This ensures that the standby temperature is only maintained when the iron is not in use.

Furthermore, the circuit's design allows for flexibility. The warm-up time and standby temperature can be fine-tuned by adjusting the resistor values in the circuit. This adaptability makes it suitable for various soldering iron models, provided that the power supply requirements are met. Overall, this circuit enhances the efficiency and usability of soldering operations, making it a valuable tool for electronics engineers and hobbyists alike.Although 60/40 solder melts at about 200°C, the tip temperature of a soldering iron should be at about 370°C. This is necessary to make a good quick joint, without the risk of overheating delicate components because the iron has to be kept on the joint for too long.

Unfortunately, at this temperature, the tip oxidises rapidly and needs const ant cleaning. That`s where this circuit can help - it keeps the soldering tip to just below 200°C while the iron is at rest. Oxidisation is then negligible and the iron can be brought back up to soldering temperature in just a few seconds when needed.

In addition, normal soldering operation, where the iron is returned to rest only momentarily, is unaffected because of the thermal inertia of the iron. Two 555 timers (IC1 & IC2) form the heart of the circuit. IC1 is wired as a monostable and provides an initial warm-up time of about 45 seconds to bring the iron up to temperature.

At the end of this period, its pin 3 output switches high and IC2 (which is wired in astable configuration) switches the iron on - via relay RLY1 - for about one second in six to maintain the standby temperature. The presence of the iron in its stand is sensed by electrical contact between the two and some slight modification of the stand may be necessary to achieve this.

When the iron is at rest, Q1`s base is pulled low and so Q1 is off. Conversely, when the iron is out of its stand, Q1 turns on and pulls pins 2 & 6 of IC2 high, to inhibit its operation. During this time, pin 3 of IC2 is low and so the iron is continuously powered via RLY1`s normally closed (NC) contacts.

Note that the particular soldering iron that the circuit was designed for has its own 24V supply transformer. Other irons may need different power supply arrangements. The warm-up time and standby temperature can be varied by altering R2 and R5, as necessary. 🔗 External reference

This circuit utilizes two 555 timer ICs to manage the heating and standby operation of a soldering iron effectively. The first timer (IC1) is configured in monostable mode, which allows it to trigger a warm-up sequence for the soldering iron. Upon activation, IC1 provides a high output for a predetermined duration, ensuring that the soldering iron reaches its optimal operating temperature efficiently. The second timer (IC2), configured in astable mode, takes over once the warm-up period is completed. IC2 generates a pulse width modulation (PWM) signal that controls relay RLY1, which in turn regulates the power supplied to the soldering iron.

The relay acts as a switch that connects or disconnects the power to the soldering iron based on the output from IC2. The PWM control helps maintain the soldering iron at a lower standby temperature, reducing oxidation and prolonging the life of the soldering tip. The detection mechanism for the soldering iron's presence is critical; it relies on a simple electrical contact that indicates when the iron is placed back in its stand. This ensures that the standby temperature is only maintained when the iron is not in use.

Furthermore, the circuit's design allows for flexibility. The warm-up time and standby temperature can be fine-tuned by adjusting the resistor values in the circuit. This adaptability makes it suitable for various soldering iron models, provided that the power supply requirements are met. Overall, this circuit enhances the efficiency and usability of soldering operations, making it a valuable tool for electronics engineers and hobbyists alike.Although 60/40 solder melts at about 200°C, the tip temperature of a soldering iron should be at about 370°C. This is necessary to make a good quick joint, without the risk of overheating delicate components because the iron has to be kept on the joint for too long.

Unfortunately, at this temperature, the tip oxidises rapidly and needs const ant cleaning. That`s where this circuit can help - it keeps the soldering tip to just below 200°C while the iron is at rest. Oxidisation is then negligible and the iron can be brought back up to soldering temperature in just a few seconds when needed.

In addition, normal soldering operation, where the iron is returned to rest only momentarily, is unaffected because of the thermal inertia of the iron. Two 555 timers (IC1 & IC2) form the heart of the circuit. IC1 is wired as a monostable and provides an initial warm-up time of about 45 seconds to bring the iron up to temperature.

At the end of this period, its pin 3 output switches high and IC2 (which is wired in astable configuration) switches the iron on - via relay RLY1 - for about one second in six to maintain the standby temperature. The presence of the iron in its stand is sensed by electrical contact between the two and some slight modification of the stand may be necessary to achieve this.

When the iron is at rest, Q1`s base is pulled low and so Q1 is off. Conversely, when the iron is out of its stand, Q1 turns on and pulls pins 2 & 6 of IC2 high, to inhibit its operation. During this time, pin 3 of IC2 is low and so the iron is continuously powered via RLY1`s normally closed (NC) contacts.

Note that the particular soldering iron that the circuit was designed for has its own 24V supply transformer. Other irons may need different power supply arrangements. The warm-up time and standby temperature can be varied by altering R2 and R5, as necessary. 🔗 External reference