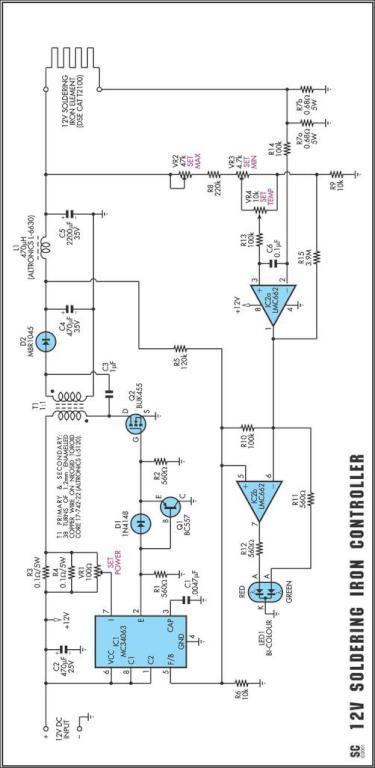

Temperature-Controlled Soldering Iron

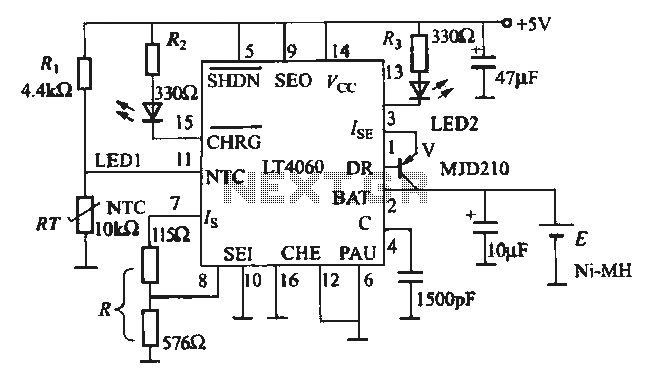

One reason why commercial soldering stations are expensive is that they typically require soldering irons with built-in temperature sensors.

Commercial soldering stations are designed to provide precise temperature control and consistency during soldering operations, which is essential for achieving reliable and high-quality solder joints. The inclusion of built-in temperature sensors in soldering irons allows for real-time monitoring and adjustment of the soldering temperature. This feature is critical in preventing overheating, which can damage sensitive electronic components, as well as ensuring that the solder melts at the appropriate temperature for optimal adhesion.

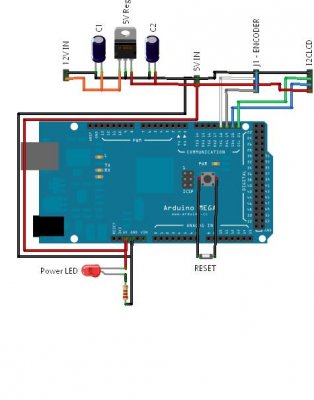

In addition to temperature sensors, commercial soldering stations often incorporate advanced features such as programmable temperature settings, digital displays for easy reading, and automatic shut-off mechanisms for safety. These stations may also include interchangeable tips, allowing users to select the appropriate tip size and shape for various applications, enhancing versatility.

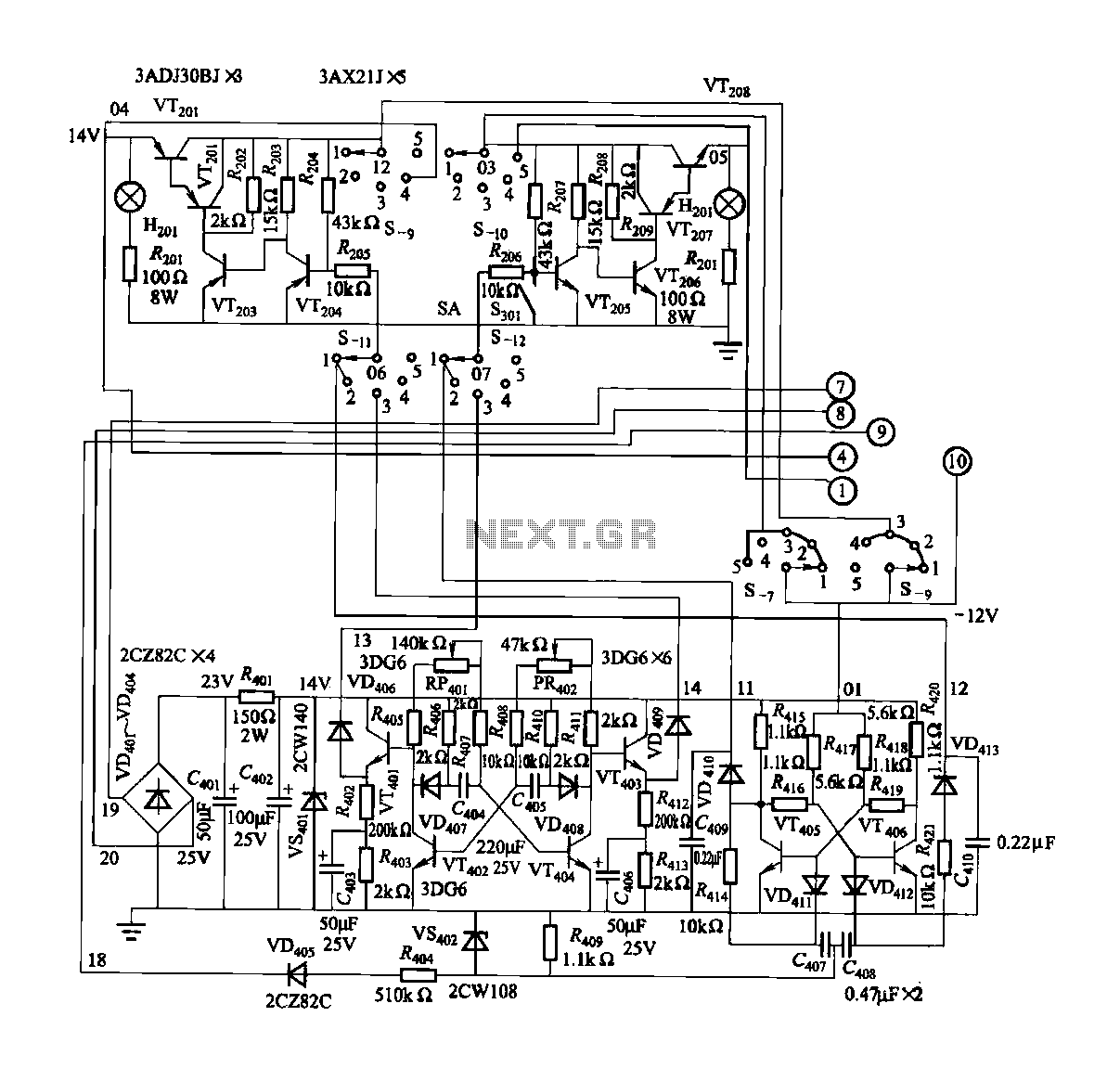

The design of a commercial soldering station typically involves a robust power supply capable of delivering stable voltage and current, along with a well-insulated handle for user comfort and safety. Furthermore, many models offer additional functionalities such as desoldering capabilities, fume extraction systems, and integrated work surfaces, which contribute to their higher cost compared to basic soldering tools.

Overall, the investment in a commercial soldering station is justified by the enhanced performance, safety features, and the ability to handle a wide range of soldering tasks efficiently.One reason why commercial soldering stations are expensive is that, in general, they require the use of soldering irons with inbuilt temperature sensors,.. 🔗 External reference

Commercial soldering stations are designed to provide precise temperature control and consistency during soldering operations, which is essential for achieving reliable and high-quality solder joints. The inclusion of built-in temperature sensors in soldering irons allows for real-time monitoring and adjustment of the soldering temperature. This feature is critical in preventing overheating, which can damage sensitive electronic components, as well as ensuring that the solder melts at the appropriate temperature for optimal adhesion.

In addition to temperature sensors, commercial soldering stations often incorporate advanced features such as programmable temperature settings, digital displays for easy reading, and automatic shut-off mechanisms for safety. These stations may also include interchangeable tips, allowing users to select the appropriate tip size and shape for various applications, enhancing versatility.

The design of a commercial soldering station typically involves a robust power supply capable of delivering stable voltage and current, along with a well-insulated handle for user comfort and safety. Furthermore, many models offer additional functionalities such as desoldering capabilities, fume extraction systems, and integrated work surfaces, which contribute to their higher cost compared to basic soldering tools.

Overall, the investment in a commercial soldering station is justified by the enhanced performance, safety features, and the ability to handle a wide range of soldering tasks efficiently.One reason why commercial soldering stations are expensive is that, in general, they require the use of soldering irons with inbuilt temperature sensors,.. 🔗 External reference