Starting Capacitors

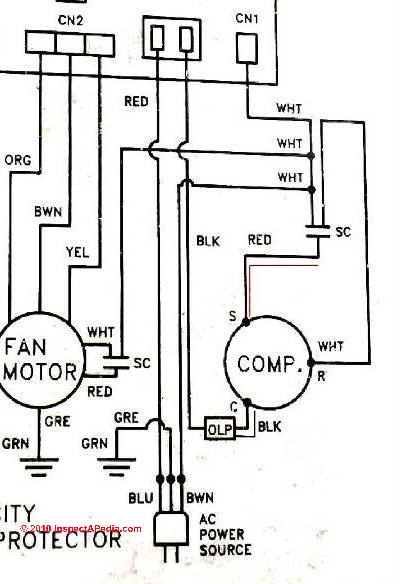

Instructions for electric motor start-run capacitors include the use of starting capacitors for air conditioner compressor motors and other electric motors like pumps. This involves diagnostic checks for start or run capacitors, including how to use a volt-ohm meter (VOM) or multimeter to test a motor starting capacitor. Additional information covers how to fix or replace a hard-starting air conditioner compressor or other electric motors, as well as how to inspect, test, or install an air conditioner motor starting capacitor. Warnings regarding the remaining life of hard-starting air conditioner or heat pump compressor motors are also provided, along with a question-and-answer section about installing a hard-start capacitor to facilitate the operation of an air conditioner motor, fan motor, or other electric motors.

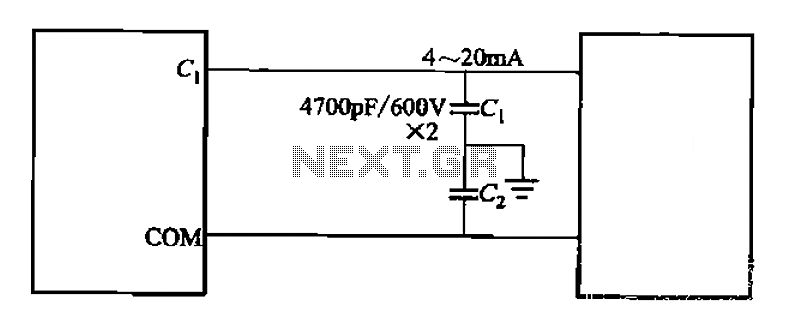

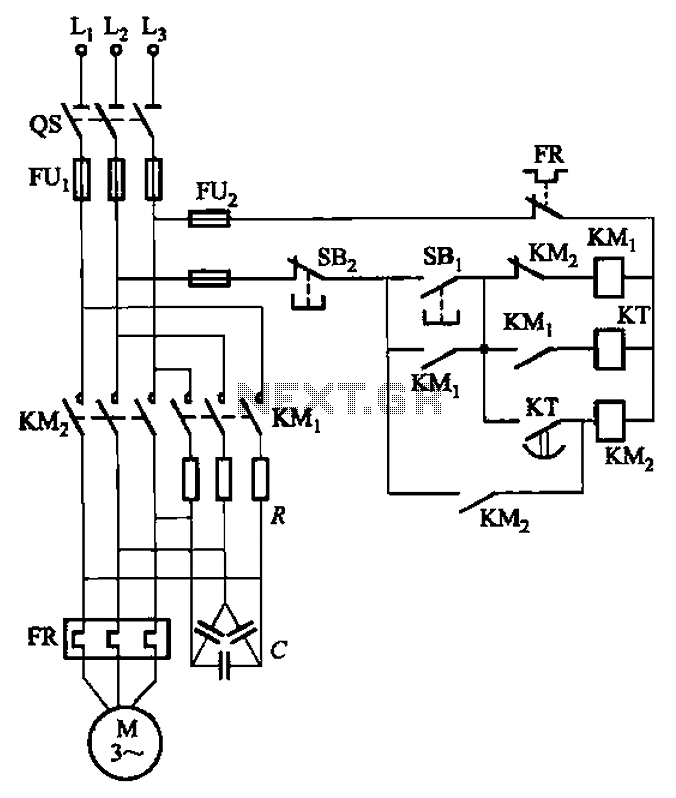

Electric motor start-run capacitors are crucial components in the operation of various electric motors, particularly in air conditioning systems and pumps. These capacitors are designed to provide the necessary boost of electrical energy to start the motor and keep it running efficiently. Starting capacitors are typically employed during the initial startup phase, while run capacitors are used to maintain the motor's operation once it is running.

To ensure optimal performance and longevity of the motor, it is essential to conduct diagnostic checks on these capacitors. A volt-ohm meter (VOM) or multimeter can be used to measure the capacitance and resistance of the capacitor, which helps in identifying any faults. A properly functioning capacitor should exhibit specific capacitance values within the manufacturer’s specifications. If the readings are significantly lower or higher, it may indicate that the capacitor is failing and needs replacement.

In cases where an air conditioner compressor or other electric motor is hard-starting, troubleshooting steps should be taken. This may involve inspecting the capacitor for physical damage, such as bulging or leaking, which are signs of failure. If the capacitor is found to be defective, it should be replaced with one that matches the specifications of the original component to ensure compatibility and safety.

Warnings regarding the remaining life of hard-starting air conditioner or heat pump compressor motors are important to consider. Continuous operation with a failing capacitor can lead to further damage to the motor, resulting in costly repairs or replacements. It is advisable to monitor the performance of the capacitor regularly and replace it proactively to avoid unexpected failures.

Additionally, a question-and-answer section can provide valuable insights into common concerns related to the installation of hard-start capacitors. This may include inquiries about the correct sizing of the capacitor, installation procedures, and troubleshooting tips for common issues encountered during operation. These resources can enhance the understanding and effectiveness of using starting capacitors in electric motors, ensuring reliable and efficient operation.Electric motor start-run capacitor instructions: Use of air conditioner compressor motor starting capacitors Use of starting capacitors on electric motors for air conditioning, pumps, etc. Start or Run Capacitor Diagnostic Checks: How to Use a VOM or Multimeter to Test a Motor Starting Capacitor How to fix or replace a hard-starting air conditioner compressor or other hard starting electric motor How to inspect, test, or install an air conditioner motor starting capacitor Warnings about remaining life of hard-starting air conditioner or heat pump compressor motors Questions & answers about installing a hard-start capacitor to get an air conditioner motor, fan motor, or other electric motor running.

.. 🔗 External reference

Electric motor start-run capacitors are crucial components in the operation of various electric motors, particularly in air conditioning systems and pumps. These capacitors are designed to provide the necessary boost of electrical energy to start the motor and keep it running efficiently. Starting capacitors are typically employed during the initial startup phase, while run capacitors are used to maintain the motor's operation once it is running.

To ensure optimal performance and longevity of the motor, it is essential to conduct diagnostic checks on these capacitors. A volt-ohm meter (VOM) or multimeter can be used to measure the capacitance and resistance of the capacitor, which helps in identifying any faults. A properly functioning capacitor should exhibit specific capacitance values within the manufacturer’s specifications. If the readings are significantly lower or higher, it may indicate that the capacitor is failing and needs replacement.

In cases where an air conditioner compressor or other electric motor is hard-starting, troubleshooting steps should be taken. This may involve inspecting the capacitor for physical damage, such as bulging or leaking, which are signs of failure. If the capacitor is found to be defective, it should be replaced with one that matches the specifications of the original component to ensure compatibility and safety.

Warnings regarding the remaining life of hard-starting air conditioner or heat pump compressor motors are important to consider. Continuous operation with a failing capacitor can lead to further damage to the motor, resulting in costly repairs or replacements. It is advisable to monitor the performance of the capacitor regularly and replace it proactively to avoid unexpected failures.

Additionally, a question-and-answer section can provide valuable insights into common concerns related to the installation of hard-start capacitors. This may include inquiries about the correct sizing of the capacitor, installation procedures, and troubleshooting tips for common issues encountered during operation. These resources can enhance the understanding and effectiveness of using starting capacitors in electric motors, ensuring reliable and efficient operation.Electric motor start-run capacitor instructions: Use of air conditioner compressor motor starting capacitors Use of starting capacitors on electric motors for air conditioning, pumps, etc. Start or Run Capacitor Diagnostic Checks: How to Use a VOM or Multimeter to Test a Motor Starting Capacitor How to fix or replace a hard-starting air conditioner compressor or other hard starting electric motor How to inspect, test, or install an air conditioner motor starting capacitor Warnings about remaining life of hard-starting air conditioner or heat pump compressor motors Questions & answers about installing a hard-start capacitor to get an air conditioner motor, fan motor, or other electric motor running.

.. 🔗 External reference