Stepper Motor Controllers

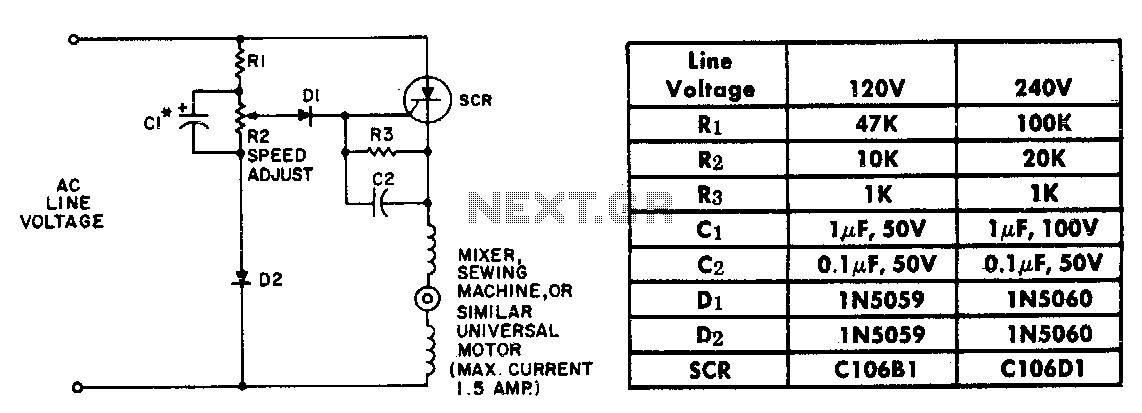

The circuit is straightforward and cost-effective. This is advantageous since most commercially available stepper motor controller ICs tend to be quite pricey. It is constructed using standard components and can be easily modified for computer control. By utilizing inexpensive surplus transistors and a stepper motor, the overall cost of the circuit can be maintained below $10.

The described circuit serves as a basic stepper motor controller, leveraging standard electronic components to create an economical solution for driving stepper motors. The design typically includes a microcontroller or a simple control logic circuit that outputs control signals to the transistors, which act as switches to energize the motor coils in the correct sequence.

The circuit can incorporate a H-bridge configuration for bidirectional control of the stepper motor, allowing it to rotate in both clockwise and counterclockwise directions. Each transistor in the circuit is responsible for controlling one phase of the motor, enabling precise control over the stepping sequence.

To ensure compatibility with various stepper motors, the circuit should be designed to handle the motor's voltage and current ratings. The use of surplus transistors is advantageous as it reduces costs, but care must be taken to select transistors that can handle the necessary load without overheating.

Additionally, the circuit can be connected to a computer through a USB interface or a serial communication protocol, allowing for easy programming and control via software. This adaptability makes the circuit suitable for various applications, including robotics, CNC machines, and automated systems, where precise movement control is required.

In conclusion, this circuit represents a practical and economical solution for controlling stepper motors, making it accessible for hobbyists and professionals alike. Its simplicity and adaptability to computer control enhance its utility across a range of applications.The circuit is very simple and inexpensive. This is good thing because most commercial stepper motor controller ICs are quite expensive. This circuit is built from standard components and can easily be adapted to be controlled by a computer. If you use cheap surplus transistors and stepper motor, the price of the circuit can be kept to under $10.

🔗 External reference

The described circuit serves as a basic stepper motor controller, leveraging standard electronic components to create an economical solution for driving stepper motors. The design typically includes a microcontroller or a simple control logic circuit that outputs control signals to the transistors, which act as switches to energize the motor coils in the correct sequence.

The circuit can incorporate a H-bridge configuration for bidirectional control of the stepper motor, allowing it to rotate in both clockwise and counterclockwise directions. Each transistor in the circuit is responsible for controlling one phase of the motor, enabling precise control over the stepping sequence.

To ensure compatibility with various stepper motors, the circuit should be designed to handle the motor's voltage and current ratings. The use of surplus transistors is advantageous as it reduces costs, but care must be taken to select transistors that can handle the necessary load without overheating.

Additionally, the circuit can be connected to a computer through a USB interface or a serial communication protocol, allowing for easy programming and control via software. This adaptability makes the circuit suitable for various applications, including robotics, CNC machines, and automated systems, where precise movement control is required.

In conclusion, this circuit represents a practical and economical solution for controlling stepper motors, making it accessible for hobbyists and professionals alike. Its simplicity and adaptability to computer control enhance its utility across a range of applications.The circuit is very simple and inexpensive. This is good thing because most commercial stepper motor controller ICs are quite expensive. This circuit is built from standard components and can easily be adapted to be controlled by a computer. If you use cheap surplus transistors and stepper motor, the price of the circuit can be kept to under $10.

🔗 External reference