Synchronizing NJM3770A Stepper Motor Driver

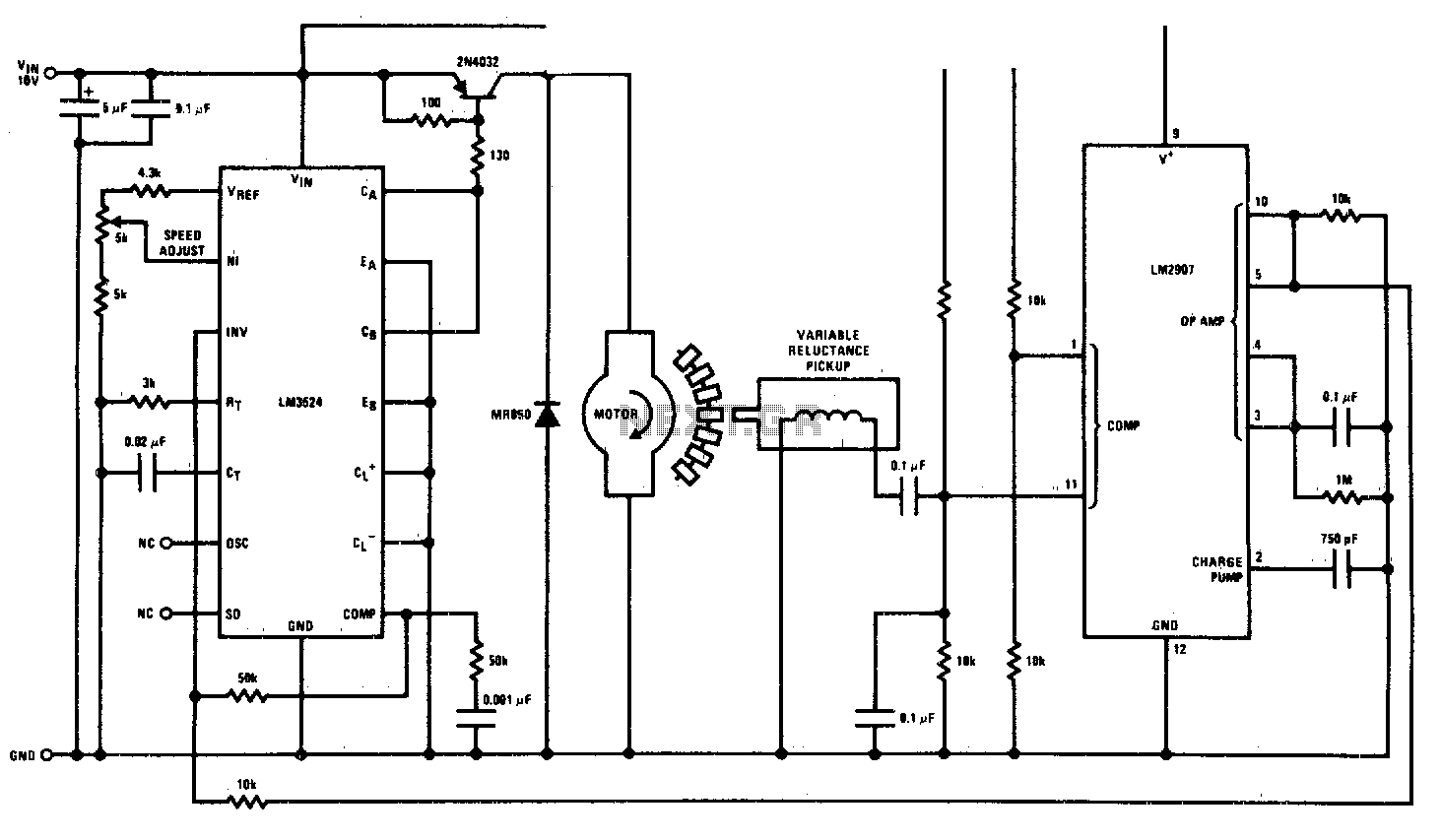

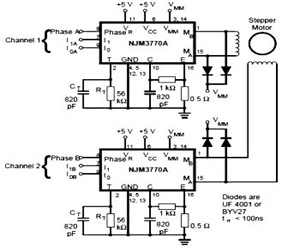

The schematic below represents a typical stepper motor driver application utilizing the NJM3770A. As illustrated in the diagram, the single-channel stepper motor drivers NJM3717 and NJM3770A operate independently and are not synchronized.

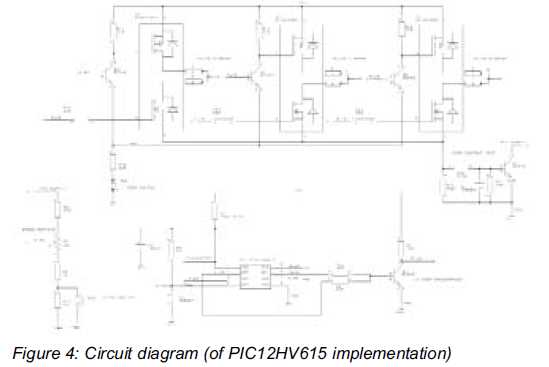

The circuit design features the NJM3770A, a dedicated stepper motor driver IC, which is capable of driving a bipolar stepper motor with high efficiency. The NJM3770A typically includes integrated control logic, current sensing, and protection features, making it suitable for applications requiring precise motor control.

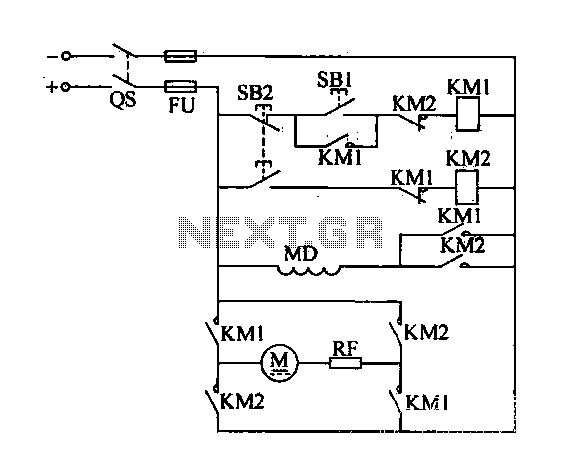

In the schematic, the NJM3717 serves as a complementary driver, providing additional control capabilities. Each driver is connected to its respective stepper motor coil, allowing for independent operation. The power supply connections are designed to provide the necessary voltage and current levels for optimal performance of both drivers.

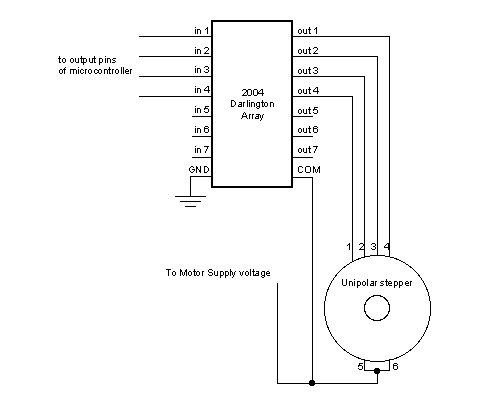

Control signals for the drivers can be generated using a microcontroller or a dedicated control circuit, which sends pulse-width modulation (PWM) signals to regulate the stepping sequence and speed of the motors. The lack of synchronization between the NJM3717 and NJM3770A allows for flexible control strategies, enabling complex motion profiles or multi-axis applications where different motors operate at varying speeds or sequences.

Additional components such as diodes for flyback protection, capacitors for filtering, and resistors for current limiting may also be included in the schematic to enhance performance and reliability. The overall design emphasizes efficiency and precision, crucial for applications in robotics, CNC machinery, and automation systems where stepper motors are employed.

This configuration allows for a versatile approach to stepper motor control, accommodating various operational requirements while ensuring robustness and ease of integration into larger systems.The schematic below appears typical stepper motor driver application with NJM3770A. As seen in the diagram, the single channel stepper motor drivers NJM3717 and NJM3770A are not synchronized 🔗 External reference

The circuit design features the NJM3770A, a dedicated stepper motor driver IC, which is capable of driving a bipolar stepper motor with high efficiency. The NJM3770A typically includes integrated control logic, current sensing, and protection features, making it suitable for applications requiring precise motor control.

In the schematic, the NJM3717 serves as a complementary driver, providing additional control capabilities. Each driver is connected to its respective stepper motor coil, allowing for independent operation. The power supply connections are designed to provide the necessary voltage and current levels for optimal performance of both drivers.

Control signals for the drivers can be generated using a microcontroller or a dedicated control circuit, which sends pulse-width modulation (PWM) signals to regulate the stepping sequence and speed of the motors. The lack of synchronization between the NJM3717 and NJM3770A allows for flexible control strategies, enabling complex motion profiles or multi-axis applications where different motors operate at varying speeds or sequences.

Additional components such as diodes for flyback protection, capacitors for filtering, and resistors for current limiting may also be included in the schematic to enhance performance and reliability. The overall design emphasizes efficiency and precision, crucial for applications in robotics, CNC machinery, and automation systems where stepper motors are employed.

This configuration allows for a versatile approach to stepper motor control, accommodating various operational requirements while ensuring robustness and ease of integration into larger systems.The schematic below appears typical stepper motor driver application with NJM3770A. As seen in the diagram, the single channel stepper motor drivers NJM3717 and NJM3770A are not synchronized 🔗 External reference