Transistor Ignition

This transistor ignition circuit enhances vehicle starting and ensures smoother engine operation, especially at both high and low RPMs. It contributes to lower fuel consumption, reduced emissions, and decreased maintenance costs. The system promotes economical and electronic driving.

The transistor ignition circuit is designed to optimize the ignition timing and improve the overall performance of an internal combustion engine. It employs a transistor-based switching mechanism that replaces traditional mechanical points, leading to more precise control over the ignition process. This increased precision allows for better combustion efficiency, which results in enhanced power output and smoother engine operation across a wider range of RPMs.

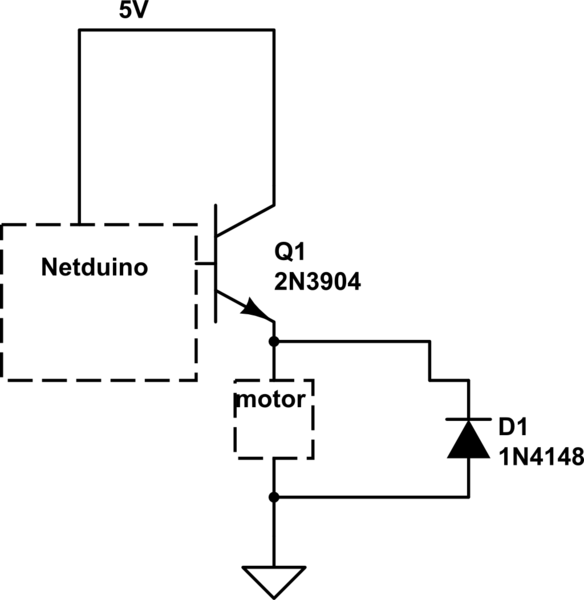

Key components of the circuit typically include a power transistor, a resistor, a capacitor, and a series of diodes. The power transistor acts as a switch that controls the flow of current to the ignition coil. When the ignition key is turned, the circuit is energized, allowing the capacitor to charge through the resistor. Once the voltage across the capacitor reaches a certain threshold, the power transistor switches on, delivering a high-voltage pulse to the ignition coil. This pulse generates a spark at the spark plugs, igniting the air-fuel mixture in the combustion chamber.

The use of a transistor instead of mechanical points eliminates issues such as point bounce and wear, resulting in increased reliability and reduced maintenance. Additionally, the circuit can be designed to include features such as adjustable timing and dwell control, allowing for further optimization based on specific engine characteristics.

Overall, this transistor ignition circuit not only improves the operational efficiency of the vehicle but also supports environmental sustainability by reducing harmful emissions. As a result, it is a valuable upgrade for enhancing vehicle performance and longevity while promoting economical driving practices.This transistor ignition circuit give your car to have better starting and smoother running, particularly at very high and very low RPM. Lower fuel consumption, less pollution, lower servicing costs. Drive economically, drive electronically.. 🔗 External reference

The transistor ignition circuit is designed to optimize the ignition timing and improve the overall performance of an internal combustion engine. It employs a transistor-based switching mechanism that replaces traditional mechanical points, leading to more precise control over the ignition process. This increased precision allows for better combustion efficiency, which results in enhanced power output and smoother engine operation across a wider range of RPMs.

Key components of the circuit typically include a power transistor, a resistor, a capacitor, and a series of diodes. The power transistor acts as a switch that controls the flow of current to the ignition coil. When the ignition key is turned, the circuit is energized, allowing the capacitor to charge through the resistor. Once the voltage across the capacitor reaches a certain threshold, the power transistor switches on, delivering a high-voltage pulse to the ignition coil. This pulse generates a spark at the spark plugs, igniting the air-fuel mixture in the combustion chamber.

The use of a transistor instead of mechanical points eliminates issues such as point bounce and wear, resulting in increased reliability and reduced maintenance. Additionally, the circuit can be designed to include features such as adjustable timing and dwell control, allowing for further optimization based on specific engine characteristics.

Overall, this transistor ignition circuit not only improves the operational efficiency of the vehicle but also supports environmental sustainability by reducing harmful emissions. As a result, it is a valuable upgrade for enhancing vehicle performance and longevity while promoting economical driving practices.This transistor ignition circuit give your car to have better starting and smoother running, particularly at very high and very low RPM. Lower fuel consumption, less pollution, lower servicing costs. Drive economically, drive electronically.. 🔗 External reference