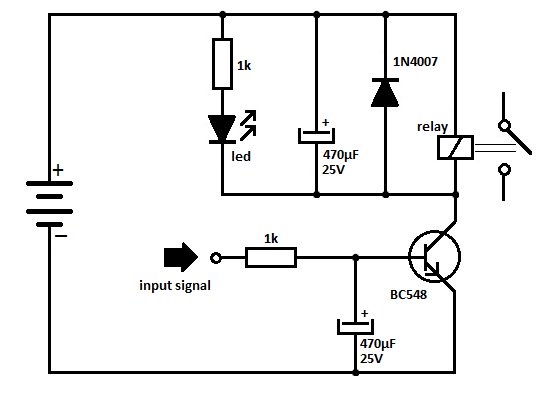

Transistor Relay Driver Circuit

One of the serious problems in relay-operated circuits is the relay clicking or chattering during the on/off operation of the relay driver transistor. This issue can lead to unreliable circuit performance and may cause premature wear of the relay contacts.

In relay-operated circuits, the phenomenon known as relay chattering occurs when the relay fails to maintain a stable state during the switching process. This instability is often caused by oscillations in the control signal driving the relay driver transistor. When the transistor is turned on or off, any noise or fluctuations in the control signal can cause the relay to rapidly switch between its on and off states, resulting in a clicking sound and potential damage to the relay contacts due to excessive wear.

To mitigate this issue, several strategies can be employed. One common solution involves adding a snubber circuit across the relay contacts to suppress voltage spikes that may occur during switching. Additionally, implementing a debounce circuit in the control signal path can help to filter out noise and ensure that only clean, stable signals are used to drive the relay.

Another approach is to utilize a relay driver circuit that incorporates hysteresis. By designing the driver with a small amount of positive feedback, the circuit can create a threshold that prevents the relay from toggling rapidly. This method stabilizes the on and off states, thus reducing chattering and enhancing the overall reliability of the circuit.

Furthermore, selecting a relay with appropriate specifications for the application, including contact ratings and response times, can also play a crucial role in minimizing chattering. Using solid-state relays can be advantageous as they typically do not exhibit the same mechanical wear as electromagnetic relays, thus providing a more reliable alternative for applications sensitive to such issues.

In summary, addressing the problem of relay chattering requires careful consideration of circuit design, component selection, and noise management to ensure stable operation and longevity of the relay system.One of the serious problems in relay operated circuits is the relay clicking or chattering during the on/off of the relay driver transistor. This problem i.. 🔗 External reference

In relay-operated circuits, the phenomenon known as relay chattering occurs when the relay fails to maintain a stable state during the switching process. This instability is often caused by oscillations in the control signal driving the relay driver transistor. When the transistor is turned on or off, any noise or fluctuations in the control signal can cause the relay to rapidly switch between its on and off states, resulting in a clicking sound and potential damage to the relay contacts due to excessive wear.

To mitigate this issue, several strategies can be employed. One common solution involves adding a snubber circuit across the relay contacts to suppress voltage spikes that may occur during switching. Additionally, implementing a debounce circuit in the control signal path can help to filter out noise and ensure that only clean, stable signals are used to drive the relay.

Another approach is to utilize a relay driver circuit that incorporates hysteresis. By designing the driver with a small amount of positive feedback, the circuit can create a threshold that prevents the relay from toggling rapidly. This method stabilizes the on and off states, thus reducing chattering and enhancing the overall reliability of the circuit.

Furthermore, selecting a relay with appropriate specifications for the application, including contact ratings and response times, can also play a crucial role in minimizing chattering. Using solid-state relays can be advantageous as they typically do not exhibit the same mechanical wear as electromagnetic relays, thus providing a more reliable alternative for applications sensitive to such issues.

In summary, addressing the problem of relay chattering requires careful consideration of circuit design, component selection, and noise management to ensure stable operation and longevity of the relay system.One of the serious problems in relay operated circuits is the relay clicking or chattering during the on/off of the relay driver transistor. This problem i.. 🔗 External reference