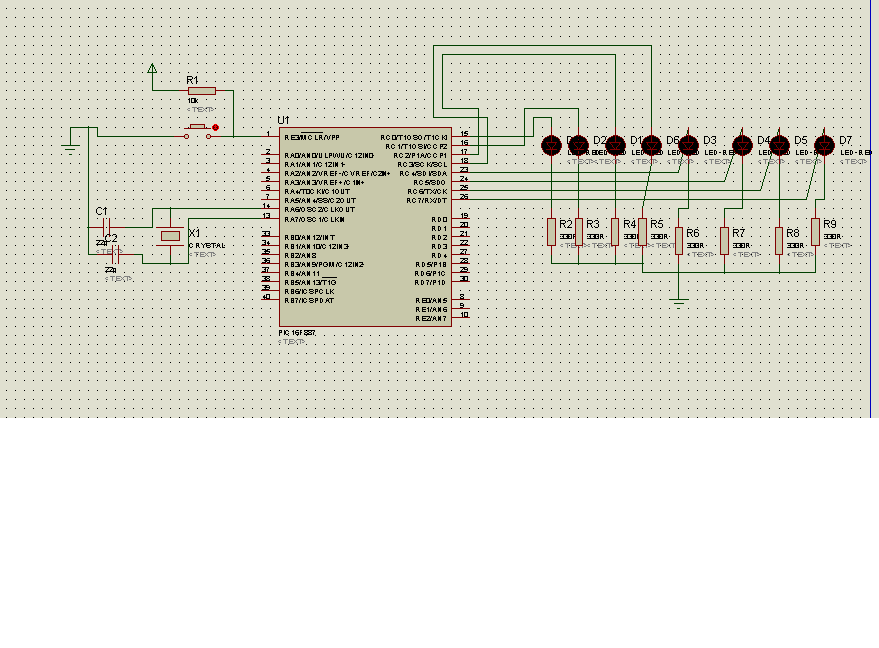

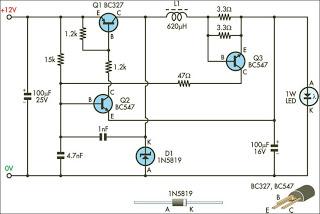

1W LED Driver

This circuit is designed to drive 1W LEDs that are commonly available. It addresses their non-linear voltage-to-current relationship and variations in forward voltage.

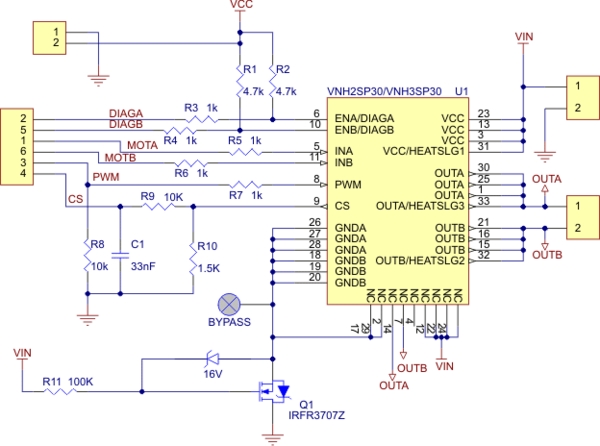

The circuit utilizes a constant current driver configuration to ensure that the LEDs operate efficiently while maintaining their rated performance. The primary components of this circuit include a power supply, a current sensing resistor, and a feedback mechanism to regulate the output current.

The power supply provides the necessary voltage to the circuit, which is typically higher than the forward voltage of the LED to ensure proper operation. The current sensing resistor is placed in series with the LED, allowing the circuit to monitor the current flowing through the LED. By measuring the voltage drop across this resistor, the circuit can determine the actual current flowing through the LED.

A feedback loop is implemented using an operational amplifier or a dedicated LED driver IC. This feedback mechanism adjusts the output voltage to maintain a constant current, compensating for variations in the LED's forward voltage due to temperature changes or manufacturing tolerances.

To enhance thermal management, appropriate heat sinking should be considered, as 1W LEDs can generate significant heat during operation. Additionally, the circuit may include protective features such as overcurrent protection, thermal shutdown, and reverse polarity protection to ensure the longevity and reliability of the LEDs.

Overall, this circuit design effectively addresses the unique characteristics of 1W LEDs, providing a reliable and efficient solution for various lighting applications.This circuit is designed to drive the 1W LEDs that are now commonly available. Their non-linear voltage to current relationship and variation in forward v.. 🔗 External reference

The circuit utilizes a constant current driver configuration to ensure that the LEDs operate efficiently while maintaining their rated performance. The primary components of this circuit include a power supply, a current sensing resistor, and a feedback mechanism to regulate the output current.

The power supply provides the necessary voltage to the circuit, which is typically higher than the forward voltage of the LED to ensure proper operation. The current sensing resistor is placed in series with the LED, allowing the circuit to monitor the current flowing through the LED. By measuring the voltage drop across this resistor, the circuit can determine the actual current flowing through the LED.

A feedback loop is implemented using an operational amplifier or a dedicated LED driver IC. This feedback mechanism adjusts the output voltage to maintain a constant current, compensating for variations in the LED's forward voltage due to temperature changes or manufacturing tolerances.

To enhance thermal management, appropriate heat sinking should be considered, as 1W LEDs can generate significant heat during operation. Additionally, the circuit may include protective features such as overcurrent protection, thermal shutdown, and reverse polarity protection to ensure the longevity and reliability of the LEDs.

Overall, this circuit design effectively addresses the unique characteristics of 1W LEDs, providing a reliable and efficient solution for various lighting applications.This circuit is designed to drive the 1W LEDs that are now commonly available. Their non-linear voltage to current relationship and variation in forward v.. 🔗 External reference