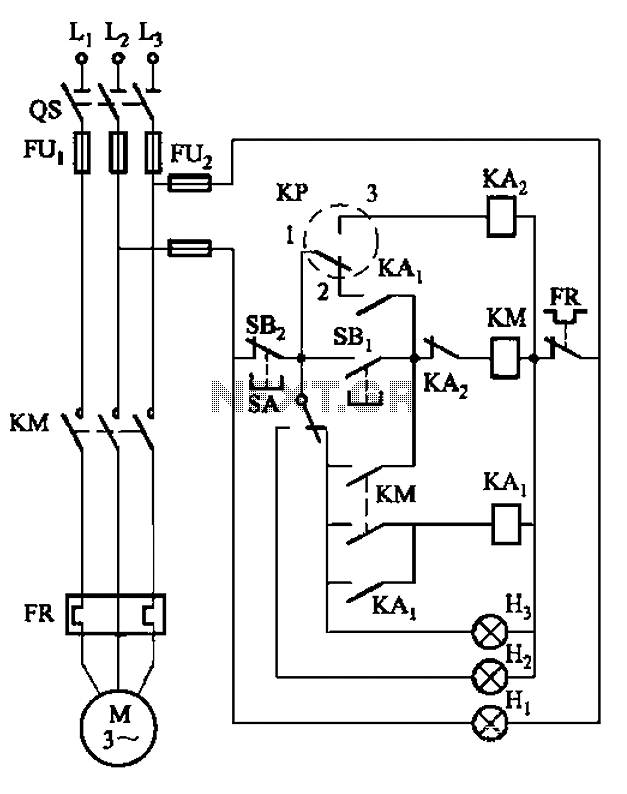

A-3-7-type air compressor control circuit

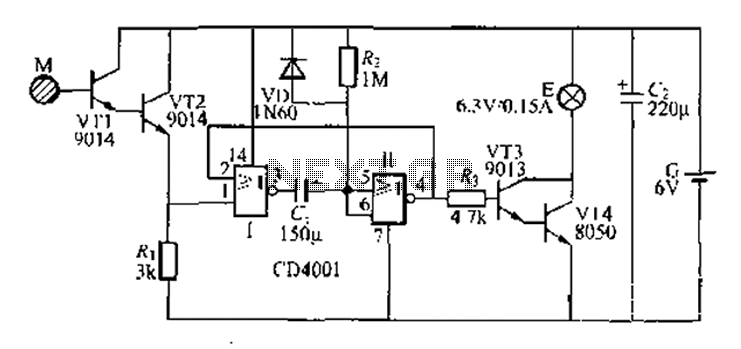

An air compressor is commonly utilized in electrical equipment factories and is typically controlled by electrical contacts. The circuit diagram is depicted in Figure 5-1. The circuit allows for both automatic and manual operation. In the diagram, KP represents the electrical contacts. When the air pressure reaches the upper limit (for example, 0.6 MPa), contact 13 closes; conversely, when the air pressure drops below the lower limit (for instance, 0.4 MPa), contacts 1-2 close. The control circuit ensures that the gas tank maintains a pressure within the required range of 0.4 to 0.6 MPa.

The air compressor circuit operates through a feedback mechanism that regulates air pressure effectively. The electrical contacts serve as pressure switches, monitoring the air pressure within the tank. When the pressure exceeds the predetermined upper limit of 0.6 MPa, the closure of contact 13 signals the compressor to stop operation, preventing over-pressurization. This is crucial for safety and equipment longevity.

On the other hand, when the pressure falls below the lower limit of 0.4 MPa, the closure of contacts 1-2 activates the compressor, initiating the air compression process to replenish the tank. This automatic operation ensures that the compressor only runs when necessary, optimizing energy consumption and extending the lifespan of the equipment.

For manual operation, the circuit may include a switch that allows an operator to start or stop the compressor regardless of the pressure readings. This feature is beneficial for maintenance or troubleshooting purposes, providing flexibility in managing the compressor's operation.

The overall design of the circuit should include safety features such as fuses or circuit breakers to protect against electrical faults. Additionally, proper labeling of the contacts and clear wiring diagrams will facilitate easy troubleshooting and maintenance. The use of reliable components, such as pressure switches rated for the specific operational range, is essential to ensure the circuit's functionality and safety.Air compressor (compressor) is commonly used in electrical equipment factory, generally controlled by the electrical contacts. Circuit shown in Figure 5-1. Circuit automatic an d manual operation. Figure, KP as electrical contacts, when the air pressure reaches the upper limit (such as 0.6MPa), the 13 contact closure; when the air pressure starts below the lower limit (eg 0. 4MPa), the contacts 1-2 closure. By the control circuit, the gas tank can always be maintained at a pressure within the range of 0.4 ~ 0.

6MPa required.

The air compressor circuit operates through a feedback mechanism that regulates air pressure effectively. The electrical contacts serve as pressure switches, monitoring the air pressure within the tank. When the pressure exceeds the predetermined upper limit of 0.6 MPa, the closure of contact 13 signals the compressor to stop operation, preventing over-pressurization. This is crucial for safety and equipment longevity.

On the other hand, when the pressure falls below the lower limit of 0.4 MPa, the closure of contacts 1-2 activates the compressor, initiating the air compression process to replenish the tank. This automatic operation ensures that the compressor only runs when necessary, optimizing energy consumption and extending the lifespan of the equipment.

For manual operation, the circuit may include a switch that allows an operator to start or stop the compressor regardless of the pressure readings. This feature is beneficial for maintenance or troubleshooting purposes, providing flexibility in managing the compressor's operation.

The overall design of the circuit should include safety features such as fuses or circuit breakers to protect against electrical faults. Additionally, proper labeling of the contacts and clear wiring diagrams will facilitate easy troubleshooting and maintenance. The use of reliable components, such as pressure switches rated for the specific operational range, is essential to ensure the circuit's functionality and safety.Air compressor (compressor) is commonly used in electrical equipment factory, generally controlled by the electrical contacts. Circuit shown in Figure 5-1. Circuit automatic an d manual operation. Figure, KP as electrical contacts, when the air pressure reaches the upper limit (such as 0.6MPa), the 13 contact closure; when the air pressure starts below the lower limit (eg 0. 4MPa), the contacts 1-2 closure. By the control circuit, the gas tank can always be maintained at a pressure within the range of 0.4 ~ 0.

6MPa required.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713