Analog Tachometer Readout

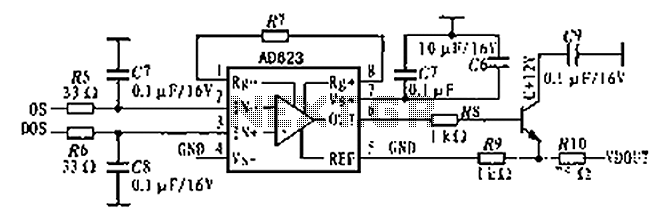

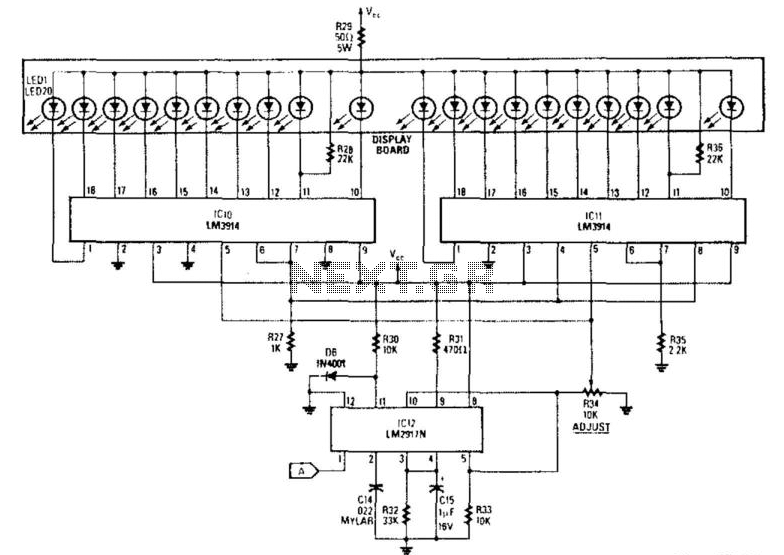

The analog display consists of a frequency/voltage converter (IC12) and bar-graph segment drivers IC10 and IC11. More: R34 is the calibration adjustment and is set so that an engine rpm of 5 000 to 7000 rpm lights the first LED (redline value).

The analog display circuit utilizes a frequency-to-voltage converter (IC12) to translate the engine RPM into a corresponding voltage level. This voltage is then processed by two bar-graph segment drivers (IC10 and IC11), which control a series of LEDs to visually represent the engine's performance. The output of IC12 is proportional to the frequency of the input signal, allowing for a direct correlation between engine speed and the displayed output.

Calibration of the circuit is achieved through the resistor R34, which adjusts the sensitivity of the system. By setting R34, the circuit can be fine-tuned to ensure that the first LED in the bar graph lights up at the desired RPM range of 5,000 to 7,000. This redline indicator serves as a visual cue for the operator, alerting them when the engine is approaching its maximum safe operating speed.

The circuit design may also include additional components such as bypass capacitors for noise reduction, and decoupling capacitors to stabilize the power supply to the integrated circuits. Proper layout considerations should be taken into account to minimize interference and ensure accurate readings. The use of appropriate LED drivers can enhance the brightness and visibility of the display under various lighting conditions. Overall, the combination of IC12, IC10, IC11, and R34 creates a robust analog display system for monitoring engine performance. The analog display consists of a frequency/voltage converter (IC12) and bar-graph segment drivers IC10 and IC11.

The analog display circuit utilizes a frequency-to-voltage converter (IC12) to translate the engine RPM into a corresponding voltage level. This voltage is then processed by two bar-graph segment drivers (IC10 and IC11), which control a series of LEDs to visually represent the engine's performance. The output of IC12 is proportional to the frequency of the input signal, allowing for a direct correlation between engine speed and the displayed output.

Calibration of the circuit is achieved through the resistor R34, which adjusts the sensitivity of the system. By setting R34, the circuit can be fine-tuned to ensure that the first LED in the bar graph lights up at the desired RPM range of 5,000 to 7,000. This redline indicator serves as a visual cue for the operator, alerting them when the engine is approaching its maximum safe operating speed.

The circuit design may also include additional components such as bypass capacitors for noise reduction, and decoupling capacitors to stabilize the power supply to the integrated circuits. Proper layout considerations should be taken into account to minimize interference and ensure accurate readings. The use of appropriate LED drivers can enhance the brightness and visibility of the display under various lighting conditions. Overall, the combination of IC12, IC10, IC11, and R34 creates a robust analog display system for monitoring engine performance. The analog display consists of a frequency/voltage converter (IC12) and bar-graph segment drivers IC10 and IC11.

R34 is the calibration adjustment and is set so that an engine rpm of 5 000 to 7000 rpm lights the first LED (redline value).