Arduino Online Thermometer circuit

Research has been conducted on a project aimed at enhancing understanding of electronics, networking, and programming. The project involves the construction of an online thermometer suitable for applications requiring temperature monitoring. The current work environment is a laboratory where equipment is tested, troubleshot, and calibrated, particularly in nuclear power plants. Each module must undergo a burn-in period ranging from 24 to 360 hours under maximum load conditions. The online temperature sensor can be utilized to monitor the efficiency of the cooling system in the burn-in area. Additional applications include monitoring a server room. The Arduino platform supports up to six sensors, making it efficient for monitoring a standard-sized server room. The software Pachube can be employed to track temperature ranges over time, identifying the warmest areas of servers and equipment. This data can be integrated with another program to send warning emails to administrators if the room temperature rises unexpectedly. A network cable is necessary to connect the Ethernet shield to a router; if directly connecting to a computer, a crossover cable is required. Twisted pair wires should be arranged according to the T568B standard, which is widely used in the industry. The cut wires must be inserted into an RJ-45 plug, ensuring the white/orange wire is on the left side, with the plastic insertion tab facing down. It is crucial to verify that the wires are pushed in sufficiently before crimping. The Seeed Ethernet shield provides space on the board for terminating wires and components, although the specific version requires a breadboard for some external components. The temperature sensors require a +5 VDC, Ground, and Data wire to function. Each data line must be properly terminated from the Ethernet shield, starting with pin 3, as pins 0 and 1 are reserved for serial communication with the host, and pin 2 is used by the Ethernet shield for communication with the Arduino. The +5VDC wire is soldered to the breadboard, utilizing network cable stripped of its sheathing. A continuity check using a digital multimeter (DMM) is performed to ensure connectivity at all points, employing a paperclip on the negative lead to establish proper connections. The temperature sensors are then attached to the breadboard using network cable for the three-pin terminations. The sensors are soldered to the twisted pair wires with shrink tubing applied. The assembled circuit is connected to a laptop via USB and to a router using the constructed network cable, with the option to connect directly to a PC using a crossover cable.

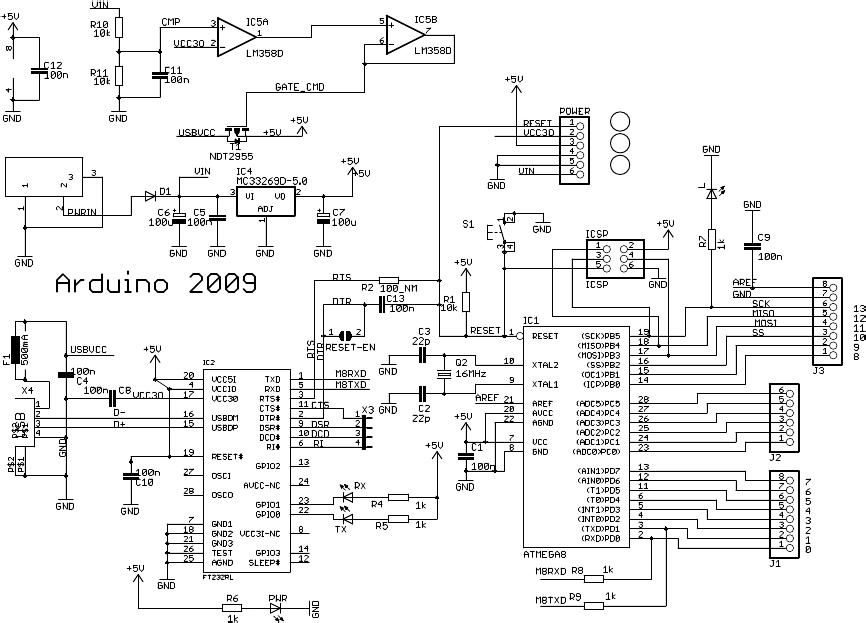

The online thermometer project utilizes an Arduino microcontroller as the core processing unit, interfaced with multiple temperature sensors to monitor environmental conditions. The sensors can be of various types, such as thermistors or digital temperature sensors like the DS18B20, which communicate via a one-wire protocol. This allows for multiple sensors to be connected in parallel on a single data line, facilitating efficient data collection.

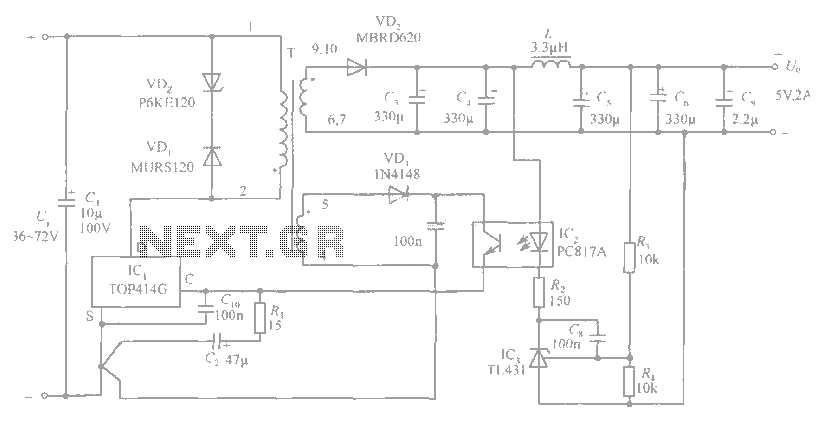

The Ethernet shield, typically based on the W5100 or W5500 chip, enables network connectivity, allowing the Arduino to send temperature data to a cloud service for remote monitoring. The integration with Pachube (now known as Xively) enables real-time data visualization and logging, which is essential for maintaining optimal conditions in critical environments like server rooms or laboratory settings.

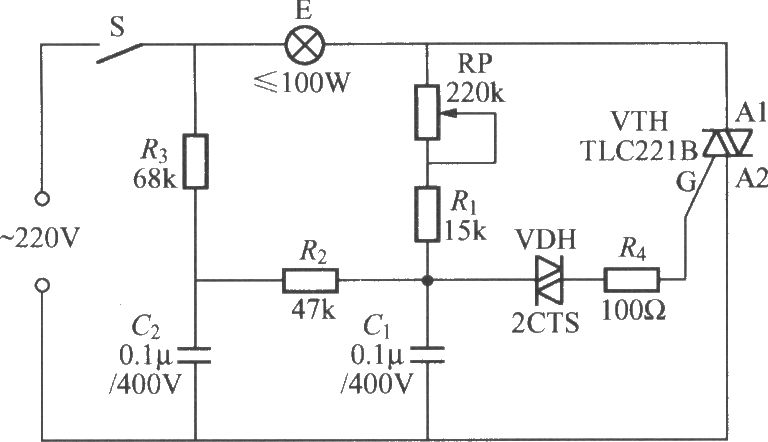

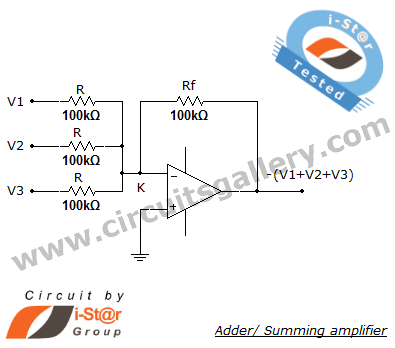

The schematic should include the Arduino connected to the Ethernet shield, with the temperature sensors connected via their respective data lines. Power distribution should be clearly indicated, ensuring that each sensor receives the necessary +5 VDC and ground connections. The RJ-45 connector wiring should be detailed, highlighting the T568B standard pinout for clarity. Additional components, such as resistors or capacitors, may be included in the schematic to ensure signal integrity and stability.

The breadboard layout should be illustrated to show how the components are arranged, with clear indications of where the sensors are connected and how the Ethernet shield is interfaced. Proper labeling of all connections and components will facilitate troubleshooting and future modifications to the circuit. The final schematic will serve as a comprehensive guide for constructing the online thermometer, ensuring that all necessary connections are made and that the system operates effectively within the intended applications.I havebeen researching a project which will help me with my understanding of electronics, networking, and programming. I decided to build an online thermometer which could be used in applications that need temperature monitoring.

I currently work in a lab environment where I test, troubleshoot, and calibrate equipment which is installed in nuclear power plants. Each module must have a burn in time ranging from 24 hrs to 360 hrs per module under max load conditions. I could use my online temperature sensor to monitor the efficiency of the cooling system in the burn in area.

Other applications could be the monitoring of a server room. The Arduino allows up to 6 sensors to be installed so this would be efficient to monitor a normal sized server room. I could use a program called Pachube to monitor the temperature ranges over time and see where the servers and equipment get the warmest.

This could then be tied into another program which could give an administrator a warning e-mail if the room temperature suddenly started rising. I first need a network cable to connect my ethernet shield to a router ( if connecting straight to a computer the cable will need to be a crossover cable).

Spread out twisted pair wires. I aligned them according to the T568B standard because it is more common in the industry. Here`s a diagram of both options and a pinout of a crossover cable. Insert the cut wires into an RJ-45 plug withwhite/orange wire on the left side. Make sure that the plastic insertion tab is facing down. Also ensure that the wires are pushed in far enough by inspecting the end. If you can`t see the wire all the way to the end then push wires in further before crimping. The great thing about the Seeed ethernet shield is they leave room on the board to terminate wires and components. However the version that I got will still require a breadboard for some external components. I don`t mind thought because I love working with breadboards! The temperature sensors will need a +5 VDC, Ground, and Data wire connected to work. I will need to terminate each data line accordingly from the ethernet shield: I skipped the first few pins and started with 3 because 0 and 1 are used for the serial connection to the host.

Pin 2 is used by the Ethernet shield to communicate with the arduino as seen in Figure 1. I started out by soldering my +5VDC wire so I can have for the +VCCon my breadboard. For the wire I just used some network cable without the sheathing. Now a continuity check with a DMM to ensure connectivity at all points. I`m using a paperclip on my negative lead to push through the breadboard to make a proper connection. It`s nowtime to attach the temperature sensors to the breadboard. I`m going to use network cable for the 3 pin terminations. First solder the sensor to the twisted pair wires with shrink tube in place. I have now attached my assembled circuit to my laptop via USB. I have also attached it to my router with the network cable I built ( you can connect this directly to you PC with a crossover cable).

🔗 External reference

The online thermometer project utilizes an Arduino microcontroller as the core processing unit, interfaced with multiple temperature sensors to monitor environmental conditions. The sensors can be of various types, such as thermistors or digital temperature sensors like the DS18B20, which communicate via a one-wire protocol. This allows for multiple sensors to be connected in parallel on a single data line, facilitating efficient data collection.

The Ethernet shield, typically based on the W5100 or W5500 chip, enables network connectivity, allowing the Arduino to send temperature data to a cloud service for remote monitoring. The integration with Pachube (now known as Xively) enables real-time data visualization and logging, which is essential for maintaining optimal conditions in critical environments like server rooms or laboratory settings.

The schematic should include the Arduino connected to the Ethernet shield, with the temperature sensors connected via their respective data lines. Power distribution should be clearly indicated, ensuring that each sensor receives the necessary +5 VDC and ground connections. The RJ-45 connector wiring should be detailed, highlighting the T568B standard pinout for clarity. Additional components, such as resistors or capacitors, may be included in the schematic to ensure signal integrity and stability.

The breadboard layout should be illustrated to show how the components are arranged, with clear indications of where the sensors are connected and how the Ethernet shield is interfaced. Proper labeling of all connections and components will facilitate troubleshooting and future modifications to the circuit. The final schematic will serve as a comprehensive guide for constructing the online thermometer, ensuring that all necessary connections are made and that the system operates effectively within the intended applications.I havebeen researching a project which will help me with my understanding of electronics, networking, and programming. I decided to build an online thermometer which could be used in applications that need temperature monitoring.

I currently work in a lab environment where I test, troubleshoot, and calibrate equipment which is installed in nuclear power plants. Each module must have a burn in time ranging from 24 hrs to 360 hrs per module under max load conditions. I could use my online temperature sensor to monitor the efficiency of the cooling system in the burn in area.

Other applications could be the monitoring of a server room. The Arduino allows up to 6 sensors to be installed so this would be efficient to monitor a normal sized server room. I could use a program called Pachube to monitor the temperature ranges over time and see where the servers and equipment get the warmest.

This could then be tied into another program which could give an administrator a warning e-mail if the room temperature suddenly started rising. I first need a network cable to connect my ethernet shield to a router ( if connecting straight to a computer the cable will need to be a crossover cable).

Spread out twisted pair wires. I aligned them according to the T568B standard because it is more common in the industry. Here`s a diagram of both options and a pinout of a crossover cable. Insert the cut wires into an RJ-45 plug withwhite/orange wire on the left side. Make sure that the plastic insertion tab is facing down. Also ensure that the wires are pushed in far enough by inspecting the end. If you can`t see the wire all the way to the end then push wires in further before crimping. The great thing about the Seeed ethernet shield is they leave room on the board to terminate wires and components. However the version that I got will still require a breadboard for some external components. I don`t mind thought because I love working with breadboards! The temperature sensors will need a +5 VDC, Ground, and Data wire connected to work. I will need to terminate each data line accordingly from the ethernet shield: I skipped the first few pins and started with 3 because 0 and 1 are used for the serial connection to the host.

Pin 2 is used by the Ethernet shield to communicate with the arduino as seen in Figure 1. I started out by soldering my +5VDC wire so I can have for the +VCCon my breadboard. For the wire I just used some network cable without the sheathing. Now a continuity check with a DMM to ensure connectivity at all points. I`m using a paperclip on my negative lead to push through the breadboard to make a proper connection. It`s nowtime to attach the temperature sensors to the breadboard. I`m going to use network cable for the 3 pin terminations. First solder the sensor to the twisted pair wires with shrink tube in place. I have now attached my assembled circuit to my laptop via USB. I have also attached it to my router with the network cable I built ( you can connect this directly to you PC with a crossover cable).

🔗 External reference