Assembly of the F&DARC Square Wave Generator/Bridge

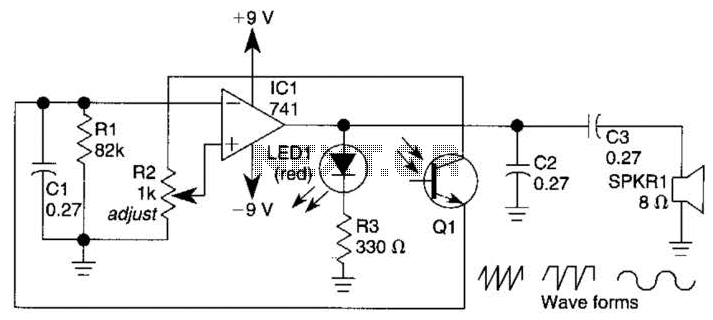

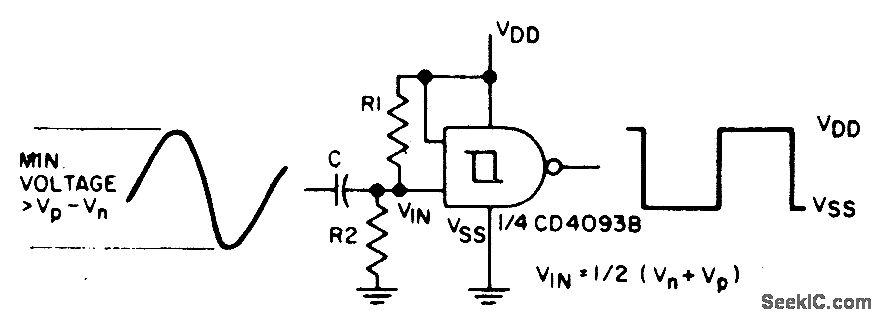

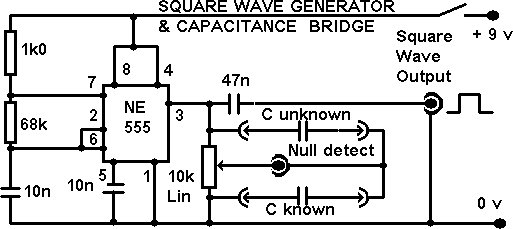

This project integrates multiple features into a compact unit. The core driver is based on an NE555 square wave generator. During development, the idea of building a square wave generator using discrete components was considered, but experiments revealed that the resulting waveform quality was insufficient, necessitating the addition of a Schmitt trigger circuit. To simplify the design while achieving a clean and symmetrical square wave suitable for various applications, the discrete component approach was ultimately abandoned. The final NE555-based square wave generator has a low component count and is easy to assemble; it generates a high-quality square wave rich in harmonics for signal tracing, with sufficient output to drive a capacitance bridge. The basic unit can be constructed on a PCB measuring just three inches square. If a capacitance substitution box is included to enhance the range and usability of the bridge, the overall dimensions extend to 3" x 6". The unit operates on a 9-volt PP3 battery. Included are circuit diagrams, a component list, a detailed layout and connection diagrams, along with photographs of the completed prototype (basic unit). The circuit diagram for the basic configuration is presented in Fig. 1, while the capacitor substitution box circuit is illustrated in Fig. 2. With the selected resistor values, this circuit oscillates at approximately 1 kHz, producing a square wave with a nearly equal mark/space ratio. If needed, the frequency can be adjusted between about 650 Hz and 7.2 kHz by changing the 68k resistor value between 10k and 160k. The frequency range can be further modified by altering the 10nF capacitor connected to pin 6 of the IC. The mark/space ratio can be adjusted by varying the resistor values, although the 1k resistor, which regulates current consumption, should not be decreased further. The bridge circuit connected to pin 3 of the IC is a standard Wheatstone Bridge configuration. The basic Wheatstone Bridge circuit is depicted in Fig. 3. When a signal source is applied across the two arms of the bridge, and either headphones or another null detector (such as the F&DARC audio amplifier/speaker project) is connected across the bridge output, a null (minimum sound) will be detected when the resistance ratio is equivalent to the capacitance ratio, or R1/R2 = C1/C2. In this project, R1 and R2 are substituted with a potentiometer; if C2 is a known value, the potentiometer can be calibrated based on the ratio of the unknown to the known capacitors. Calibration instructions are provided at the conclusion of this article. The basic unit shown in Fig. 1 can be assembled on a 3" square PCB. The complete suggested layout, including the optional capacitance substitution box, is depicted in Fig. 4, requiring a 3" x 6" PCB. The wiring for the square wave generator circuit around the IC is illustrated in Fig. 5. This, along with the photographs, should assist in clarifying the recommended layout. A pin-out diagram for the NE555 IC is provided in Fig. 6. It is important to note that this diagram shows the IC oriented on its pins, while the suggested layout utilizes the chip in a dead bug configuration. Physical construction should be completed before wiring the IC: drill the bare board to accommodate the potentiometer, sockets, switches, and choc blocks. Although the layout is not critical, it is essential to position components to allow for adequate wiring space, particularly for the battery. In the layout diagrams, light lines indicate construction lines, marking the center lines of the board.

The NE555 square wave generator serves as a versatile component in this project, providing a reliable square wave output that can be utilized in various applications, such as signal generation and testing. The choice of the NE555 timer IC is particularly advantageous due to its well-documented performance and ease of use. The circuit configuration allows for frequency adjustments, enabling users to tailor the output to specific requirements. The integration of a Wheatstone Bridge facilitates capacitance measurements, making the unit suitable for educational and practical applications in electronics.

In the implementation of the circuit, careful attention must be paid to the layout to ensure optimal performance. The use of a PCB is recommended to minimize noise and interference, which can adversely affect the square wave quality. Proper grounding techniques should be employed, and the placement of components should prioritize signal integrity. The calibration process for the potentiometer is crucial for accurate measurements, and users should follow the provided instructions meticulously to achieve reliable results.

Overall, this project not only demonstrates the functionality of the NE555 timer in generating square waves but also showcases the practical application of a Wheatstone Bridge for capacitance measurement, making it a valuable addition to any electronics toolkit.This project combines several features in one compact unit. The fundamental driver consists of a NE 555 square wave generator. During development, consideration and a certain amount of experimentation was given to the construction of a square wave unit using discrete components. Investigation showed however that the geometry of the square wave pro duced was so poor that additional complexity would be needed in the form of a Schmitt trigger circuit. In order to keep the unit as simple as possible, and at the same time produce a usefully clean and symmetrical square wave which could have further applications, the discrete approach was abandoned.

The final square wave generator using an NE555 IC has both a low component count and is simple to construct; it produces an excellent square wave, rich in harmonics (for signal tracing), and ample output to drive the capacitance bridge. The whole unit in its basic form can be constructed on a piece of PCB only three inches square. If a capacitance substitution box - which in itself also has further application - is added, to extend the range and convenience of the bridge, the entire unit occupies 3" x 6".

The unit is powered by a 9 volt PP3 battery. The following instructions include the circuit, component list, comprehensive layout and connection diagrams, and photographs of the completed prototype (basic) unit. The circuit diagram is given in Fig. 1, and is of the project in its basic form, i. e. without the capacitor substitution box. The circuit of the capacitor substitution box is shown in Fig. 2. With the the values of resistors used, this circuit oscillates at about 1 kHz, producing a square wave of approximately equal mark / space ratio.

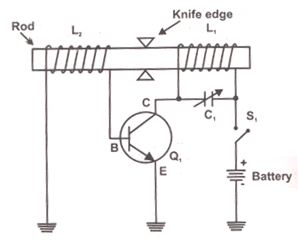

Should it be necessary at a later date, the frequency may be altered between about 650 Hz and 7. 2 kHz by altering the value of the 68k resistor between 10k and 160k. The range may be further extended by altering the value of the 10nF capacitor on pin 6 of the IC. The mark / space ratio may be altered by changing the ratio of values of the two resistors, although the 1k resistor controls the circuit`s current consumption, and should not be further reduced. The bridge circuit attached to pin 3 of the IC is a conventional Wheatstone Bridge arrangement. The Wheatstone Bridge basic circuit is shown in Fig. 3: with a signal source applied across the two arms of the bridge as shown, and either headphones or other null detector (such as the F&DARC audio amplifier / speaker project) connected across the bridge output, a null (minimum sound) will be heard when the ratio of the resistances is equivalent to the ratio of the capacitances, or R1 / R2 = C1 / C2.

In the circuit of this project, R1 and R2 are replaced by a potentiometer; if C2 is a known value, the potentiometer control may be calibrated in terms of the ratio of the unknown to the known capacitors. Calibration instructions are included at the end of this article. The basic unit as shown in Fig. 1 can be constructed on a 3" square piece of PCB. The complete suggested layout diagram, including the optional capacitance substitution box, is shown in Fig.

4, and needs a 3" x 6" piece of PCB. The square wave generator circuit wiring in the vicinity of the IC is shown in Fig. 5. This, and the photographs should help to clarify the recommended layout. A pin-out diagram for the NE 555 IC is given in Fig. 6. Note that this diagram shows the IC sitting on its pins, whereas the suggested layout uses the chip on its back (dead bug construction). Complete the physical construction before wiring the IC: drill the bare board to accommodate the potentiometer, sockets, switches and choc blocks.

Whilst the layout isn`t critical, be sure to position the components so there`s room to wire everything up, and especially so that there`s room for the battery. In the layout diagrams, the light lines are construction lines, marking the board centre lines and d 🔗 External reference

The NE555 square wave generator serves as a versatile component in this project, providing a reliable square wave output that can be utilized in various applications, such as signal generation and testing. The choice of the NE555 timer IC is particularly advantageous due to its well-documented performance and ease of use. The circuit configuration allows for frequency adjustments, enabling users to tailor the output to specific requirements. The integration of a Wheatstone Bridge facilitates capacitance measurements, making the unit suitable for educational and practical applications in electronics.

In the implementation of the circuit, careful attention must be paid to the layout to ensure optimal performance. The use of a PCB is recommended to minimize noise and interference, which can adversely affect the square wave quality. Proper grounding techniques should be employed, and the placement of components should prioritize signal integrity. The calibration process for the potentiometer is crucial for accurate measurements, and users should follow the provided instructions meticulously to achieve reliable results.

Overall, this project not only demonstrates the functionality of the NE555 timer in generating square waves but also showcases the practical application of a Wheatstone Bridge for capacitance measurement, making it a valuable addition to any electronics toolkit.This project combines several features in one compact unit. The fundamental driver consists of a NE 555 square wave generator. During development, consideration and a certain amount of experimentation was given to the construction of a square wave unit using discrete components. Investigation showed however that the geometry of the square wave pro duced was so poor that additional complexity would be needed in the form of a Schmitt trigger circuit. In order to keep the unit as simple as possible, and at the same time produce a usefully clean and symmetrical square wave which could have further applications, the discrete approach was abandoned.

The final square wave generator using an NE555 IC has both a low component count and is simple to construct; it produces an excellent square wave, rich in harmonics (for signal tracing), and ample output to drive the capacitance bridge. The whole unit in its basic form can be constructed on a piece of PCB only three inches square. If a capacitance substitution box - which in itself also has further application - is added, to extend the range and convenience of the bridge, the entire unit occupies 3" x 6".

The unit is powered by a 9 volt PP3 battery. The following instructions include the circuit, component list, comprehensive layout and connection diagrams, and photographs of the completed prototype (basic) unit. The circuit diagram is given in Fig. 1, and is of the project in its basic form, i. e. without the capacitor substitution box. The circuit of the capacitor substitution box is shown in Fig. 2. With the the values of resistors used, this circuit oscillates at about 1 kHz, producing a square wave of approximately equal mark / space ratio.

Should it be necessary at a later date, the frequency may be altered between about 650 Hz and 7. 2 kHz by altering the value of the 68k resistor between 10k and 160k. The range may be further extended by altering the value of the 10nF capacitor on pin 6 of the IC. The mark / space ratio may be altered by changing the ratio of values of the two resistors, although the 1k resistor controls the circuit`s current consumption, and should not be further reduced. The bridge circuit attached to pin 3 of the IC is a conventional Wheatstone Bridge arrangement. The Wheatstone Bridge basic circuit is shown in Fig. 3: with a signal source applied across the two arms of the bridge as shown, and either headphones or other null detector (such as the F&DARC audio amplifier / speaker project) connected across the bridge output, a null (minimum sound) will be heard when the ratio of the resistances is equivalent to the ratio of the capacitances, or R1 / R2 = C1 / C2.

In the circuit of this project, R1 and R2 are replaced by a potentiometer; if C2 is a known value, the potentiometer control may be calibrated in terms of the ratio of the unknown to the known capacitors. Calibration instructions are included at the end of this article. The basic unit as shown in Fig. 1 can be constructed on a 3" square piece of PCB. The complete suggested layout diagram, including the optional capacitance substitution box, is shown in Fig.

4, and needs a 3" x 6" piece of PCB. The square wave generator circuit wiring in the vicinity of the IC is shown in Fig. 5. This, and the photographs should help to clarify the recommended layout. A pin-out diagram for the NE 555 IC is given in Fig. 6. Note that this diagram shows the IC sitting on its pins, whereas the suggested layout uses the chip on its back (dead bug construction). Complete the physical construction before wiring the IC: drill the bare board to accommodate the potentiometer, sockets, switches and choc blocks.

Whilst the layout isn`t critical, be sure to position the components so there`s room to wire everything up, and especially so that there`s room for the battery. In the layout diagrams, the light lines are construction lines, marking the board centre lines and d 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713