autonomous mobile robot capable of avoiding obstacles circuit

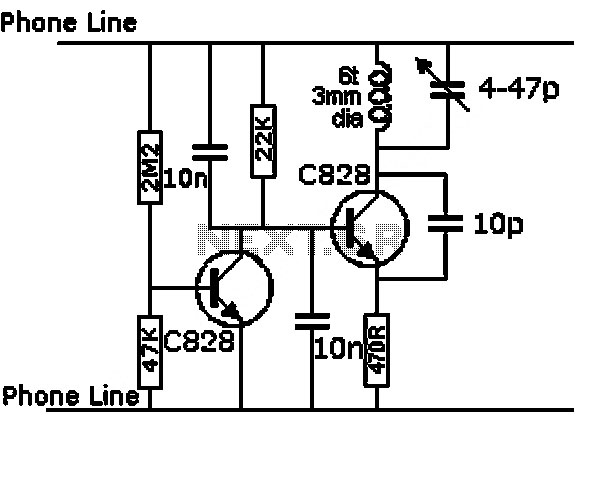

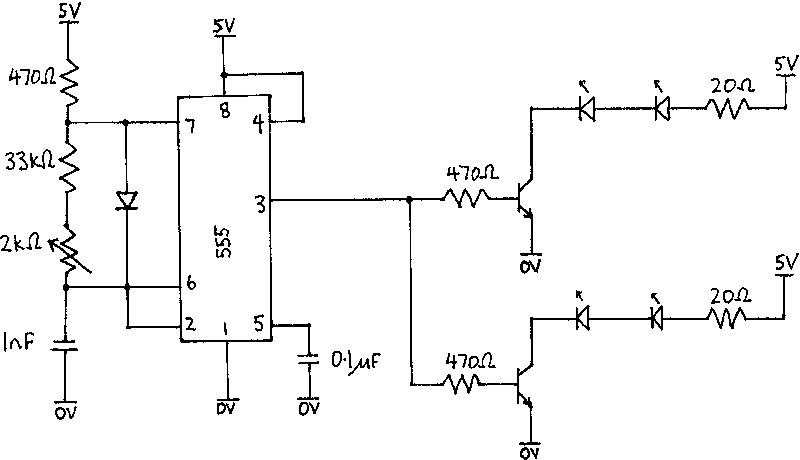

The infrared receiver requires the infrared light to be modulated at 38 kHz, which corresponds to a period of 26 µs. The specifications for the receiver suggested using a 50% duty cycle; however, this configuration did not perform as intended. To resolve this issue, the duty cycle was reduced to 5%. The infrared sources utilized were 6mm infrared LEDs. Employing a bank of four of these LEDs across the front of the robot provided uniform coverage in the sensor's field of view. The modulation of the light was accomplished by driving the infrared LEDs with a 555 timer chip. This timer was calibrated using a trimpot to achieve the exact frequency of 38 kHz, which is the center frequency of the receiver; nonetheless, the receiver is sensitive to frequencies ranging from 25 kHz to 60 kHz. The output pin of the timer chip controlled the two infrared LEDs. An ATMEL 89C2051 microcontroller was employed to manage the operation of the robot, known as dieBot. The advantage of using a microcontroller lies in its reprogrammability, which facilitates design modifications, redevelopment, and debugging. The microcontroller received inputs from the outputs of the left and right infrared sensors, while four outputs from the microcontroller were connected to the motor driving circuit (L293E). The control logic was straightforward: if the robot detected an object on the left, it would turn right, and vice versa. Challenges arose as the robot exhibited hesitance when approaching obstacles. It was observed that the output signal from the infrared receivers was digital and exhibited significant flickering before changing state. Consequently, some form of filtering was necessary for the input signal. A rudimentary filtering technique was implemented by requiring the transmitter to remain high for a duration of 0.1 seconds before registering an object. This filtering method proved effective, resulting in smoother operation of the robot. The design of dieBot was divided into three primary components: the sensor system, the motor driving system, and the logic system. The project provided all team members with insights into various relevant areas.

The infrared receiver is a critical component in robotic applications, particularly in obstacle detection and navigation systems. The modulation of infrared light at 38 kHz ensures optimal performance of the receiver, as it is tuned to respond to this frequency while remaining sensitive to a broader range. The choice of a 5% duty cycle over the initially suggested 50% enhances the reliability of signal detection, reducing the likelihood of false positives when interpreting sensor data.

The use of four 6mm infrared LEDs strategically positioned across the front of the robot maximizes the sensor's effective field of view, ensuring comprehensive coverage for obstacle detection. The 555 timer serves as an efficient means of generating the required modulation frequency, with the trimpot allowing for precise tuning to match the receiver's specifications. This level of control is essential for ensuring that the signal remains within the acceptable frequency range, thereby minimizing interference from extraneous light sources.

The integration of the ATMEL 89C2051 microcontroller facilitates advanced control logic, enabling adaptive responses based on sensor inputs. The design allows for reprogramming, which is advantageous for iterative development and testing. The connection of the microcontroller to the L293E motor driver circuit provides a robust mechanism for controlling motor functions, allowing for directional changes based on obstacle detection.

The implementation of a basic filtering strategy to mitigate signal flickering demonstrates a practical approach to improving sensor reliability. By requiring a sustained high signal before registering an obstacle, the system reduces the impact of transient noise, resulting in smoother navigation and enhanced operational efficiency. The division of the project into distinct subsystems—sensor, motor driving, and logic—ensures a modular design, facilitating troubleshooting and future enhancements. Overall, this project exemplifies the integration of various electronic components to achieve a cohesive and functional robotic system.The infra-red receiver requires the infra-red light to be modulated at 38 kHz, this is quivalent to a period of 26 µs. The specifications on the receiver suggested using a 50% duty cycle. We found however that this did not work the way we intended. To overcome this we reduced the duty cycle to 5%. The infra-red sources used were 6mm infra-red (88 0 nm) LEDs. Using a bank of four of these LED`s across the front of the robot gave an even coverage in the sensor ’s field of view. To modulate the light we drove the infra red LEDs using a 555 timer chip. This timer was tuned using a trimpot to give exactly 38 kHz, which is the receiver ’s centre frequency, however the receiver is susceptible to frequencies between 25 khz and 60 kHz.

The output pin of this timer chip drove the two infra-red LEDs. An ATMEL 89C2051 micro controller was used to control the operation of the dieBot. The benefit of using a micro controller is that the function of the robot can be reprogrammed. This allows for easy design, redevelopment and dubugging. The two inputs to the micro were the outputs from the left and right infra red sensors. There were four outputs from the micro that were connected the motor driving circuit (L293E). The logic of the controller was simple, if the robot sensed a object on the left it would turn right and visa versa. We found difficulties that the robot was very apprehensive when it approached an obstacle. It was found that the ouput signal from the infra red receivers was a digital signal and flickered greatly before changing state.

Some form of filtering had to be performed on the input signal. A crude form of filterering was achieved by waiting for the transmitter to detect high for a period of 0. 1 seconds before actually sensing an object. This method of filtering was successful and the operation of the robot performed a lot smoother. The design of DieBot was split into three main aspects the sensor system, motor driving system and the logic system.

The project has given all the team members an understanding in the following areas: 🔗 External reference

The infrared receiver is a critical component in robotic applications, particularly in obstacle detection and navigation systems. The modulation of infrared light at 38 kHz ensures optimal performance of the receiver, as it is tuned to respond to this frequency while remaining sensitive to a broader range. The choice of a 5% duty cycle over the initially suggested 50% enhances the reliability of signal detection, reducing the likelihood of false positives when interpreting sensor data.

The use of four 6mm infrared LEDs strategically positioned across the front of the robot maximizes the sensor's effective field of view, ensuring comprehensive coverage for obstacle detection. The 555 timer serves as an efficient means of generating the required modulation frequency, with the trimpot allowing for precise tuning to match the receiver's specifications. This level of control is essential for ensuring that the signal remains within the acceptable frequency range, thereby minimizing interference from extraneous light sources.

The integration of the ATMEL 89C2051 microcontroller facilitates advanced control logic, enabling adaptive responses based on sensor inputs. The design allows for reprogramming, which is advantageous for iterative development and testing. The connection of the microcontroller to the L293E motor driver circuit provides a robust mechanism for controlling motor functions, allowing for directional changes based on obstacle detection.

The implementation of a basic filtering strategy to mitigate signal flickering demonstrates a practical approach to improving sensor reliability. By requiring a sustained high signal before registering an obstacle, the system reduces the impact of transient noise, resulting in smoother navigation and enhanced operational efficiency. The division of the project into distinct subsystems—sensor, motor driving, and logic—ensures a modular design, facilitating troubleshooting and future enhancements. Overall, this project exemplifies the integration of various electronic components to achieve a cohesive and functional robotic system.The infra-red receiver requires the infra-red light to be modulated at 38 kHz, this is quivalent to a period of 26 µs. The specifications on the receiver suggested using a 50% duty cycle. We found however that this did not work the way we intended. To overcome this we reduced the duty cycle to 5%. The infra-red sources used were 6mm infra-red (88 0 nm) LEDs. Using a bank of four of these LED`s across the front of the robot gave an even coverage in the sensor ’s field of view. To modulate the light we drove the infra red LEDs using a 555 timer chip. This timer was tuned using a trimpot to give exactly 38 kHz, which is the receiver ’s centre frequency, however the receiver is susceptible to frequencies between 25 khz and 60 kHz.

The output pin of this timer chip drove the two infra-red LEDs. An ATMEL 89C2051 micro controller was used to control the operation of the dieBot. The benefit of using a micro controller is that the function of the robot can be reprogrammed. This allows for easy design, redevelopment and dubugging. The two inputs to the micro were the outputs from the left and right infra red sensors. There were four outputs from the micro that were connected the motor driving circuit (L293E). The logic of the controller was simple, if the robot sensed a object on the left it would turn right and visa versa. We found difficulties that the robot was very apprehensive when it approached an obstacle. It was found that the ouput signal from the infra red receivers was a digital signal and flickered greatly before changing state.

Some form of filtering had to be performed on the input signal. A crude form of filterering was achieved by waiting for the transmitter to detect high for a period of 0. 1 seconds before actually sensing an object. This method of filtering was successful and the operation of the robot performed a lot smoother. The design of DieBot was split into three main aspects the sensor system, motor driving system and the logic system.

The project has given all the team members an understanding in the following areas: 🔗 External reference