avr Piezoelectric Sensor and the ADC

The intention is to utilize the sensor as a force sensor. It has been observed that the voltage output increases with the amount of pressure applied, although this output is only sustained for a brief period. This behavior is anticipated. The inquiry pertains to the method of connecting the sensor to the Analog-to-Digital Converter (ADC). When significant pressure is applied, the piezoelectric sensor produces a voltage exceeding 10 V, while a gentle touch yields approximately 1.3 V. It is understood that the microcontroller can only handle voltages up to 5 V to prevent potential damage. This understanding raises a question regarding the current output from the piezo and whether its low magnitude affects the situation.

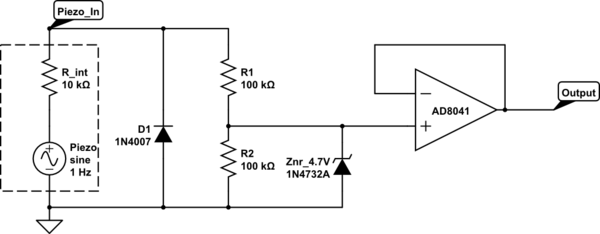

To integrate a piezoelectric sensor as a force sensor into a circuit with an ADC, it is essential to consider the voltage levels produced by the sensor under varying pressure conditions. The piezoelectric sensor generates a high output voltage, which can exceed 10 V under substantial force. However, the microcontroller's ADC input is limited to a maximum of 5 V. Therefore, a voltage divider or signal conditioning circuit is necessary to ensure that the voltage levels are safe for the microcontroller.

A voltage divider can be constructed using two resistors, R1 and R2, where the output voltage (Vout) is given by the formula:

\[ V_{out} = V_{in} \times \frac{R2}{R1 + R2} \]

In this case, R1 should be chosen to limit the maximum voltage to 5 V when the input (Vin) reaches 10 V. For example, if R1 is 10 kΩ and R2 is 5 kΩ, the output voltage can be calculated as follows:

\[ V_{out} = 10 V \times \frac{5 kΩ}{10 kΩ + 5 kΩ} = 3.33 V \]

This configuration ensures that even at maximum pressure, the output voltage remains within the safe operating limits of the microcontroller.

Additionally, it is important to implement a capacitor in parallel with the output to filter high-frequency noise and stabilize the voltage reading. A small capacitor (e.g., 1 µF) can help smooth out the transient spikes caused by the piezoelectric effect, allowing for more accurate ADC readings.

Finally, it is advisable to include a clamping diode circuit to protect the microcontroller from any potential voltage spikes that may occur when the sensor is subjected to sudden impacts. This can be achieved using a Zener diode rated for 5.1 V in parallel with the ADC input, which will clamp any excessive voltage and safeguard the microcontroller from damage.

In summary, the integration of the piezoelectric sensor into the ADC circuit requires careful consideration of voltage levels, the implementation of a voltage divider, filtering capacitors, and protective components to ensure reliable and safe operation.The reason being is that I would like to use the sensor as a force sensor. I noticed that the harder I press it, the higher a voltage it delivers (but for a very short time). This is expected behavior, of course. What I am wondering is how I would connect it to the ADC. I mean, when I press it really hard, the piezo registers upward of 10 V. When I press it softly, it usually gives me around 1. 3 V. As I understand it, the micrcontroller cannot take anything more than 5V, or else I run the risk of damaging it. Is this correct I mean, I am guessing the current coming out from the piezo is extremely small, though I don`t know if that changes the situation.

🔗 External reference

To integrate a piezoelectric sensor as a force sensor into a circuit with an ADC, it is essential to consider the voltage levels produced by the sensor under varying pressure conditions. The piezoelectric sensor generates a high output voltage, which can exceed 10 V under substantial force. However, the microcontroller's ADC input is limited to a maximum of 5 V. Therefore, a voltage divider or signal conditioning circuit is necessary to ensure that the voltage levels are safe for the microcontroller.

A voltage divider can be constructed using two resistors, R1 and R2, where the output voltage (Vout) is given by the formula:

\[ V_{out} = V_{in} \times \frac{R2}{R1 + R2} \]

In this case, R1 should be chosen to limit the maximum voltage to 5 V when the input (Vin) reaches 10 V. For example, if R1 is 10 kΩ and R2 is 5 kΩ, the output voltage can be calculated as follows:

\[ V_{out} = 10 V \times \frac{5 kΩ}{10 kΩ + 5 kΩ} = 3.33 V \]

This configuration ensures that even at maximum pressure, the output voltage remains within the safe operating limits of the microcontroller.

Additionally, it is important to implement a capacitor in parallel with the output to filter high-frequency noise and stabilize the voltage reading. A small capacitor (e.g., 1 µF) can help smooth out the transient spikes caused by the piezoelectric effect, allowing for more accurate ADC readings.

Finally, it is advisable to include a clamping diode circuit to protect the microcontroller from any potential voltage spikes that may occur when the sensor is subjected to sudden impacts. This can be achieved using a Zener diode rated for 5.1 V in parallel with the ADC input, which will clamp any excessive voltage and safeguard the microcontroller from damage.

In summary, the integration of the piezoelectric sensor into the ADC circuit requires careful consideration of voltage levels, the implementation of a voltage divider, filtering capacitors, and protective components to ensure reliable and safe operation.The reason being is that I would like to use the sensor as a force sensor. I noticed that the harder I press it, the higher a voltage it delivers (but for a very short time). This is expected behavior, of course. What I am wondering is how I would connect it to the ADC. I mean, when I press it really hard, the piezo registers upward of 10 V. When I press it softly, it usually gives me around 1. 3 V. As I understand it, the micrcontroller cannot take anything more than 5V, or else I run the risk of damaging it. Is this correct I mean, I am guessing the current coming out from the piezo is extremely small, though I don`t know if that changes the situation.

🔗 External reference