Bachmann Sound Tips

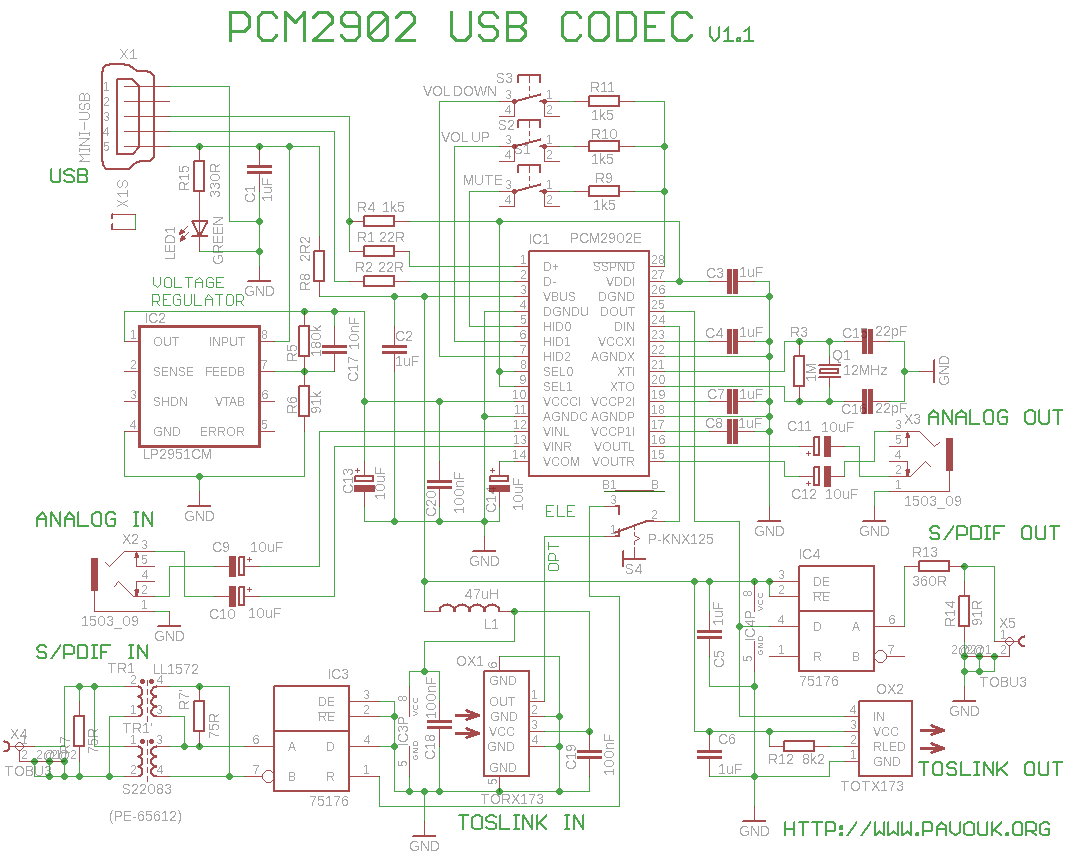

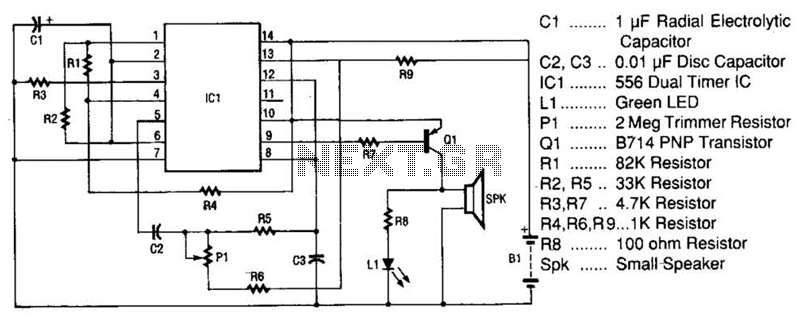

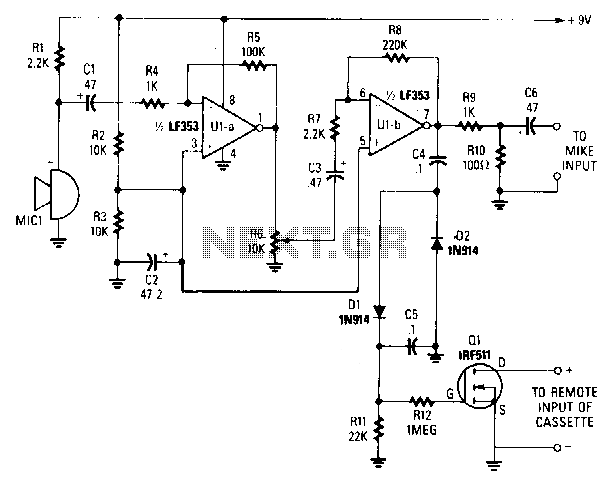

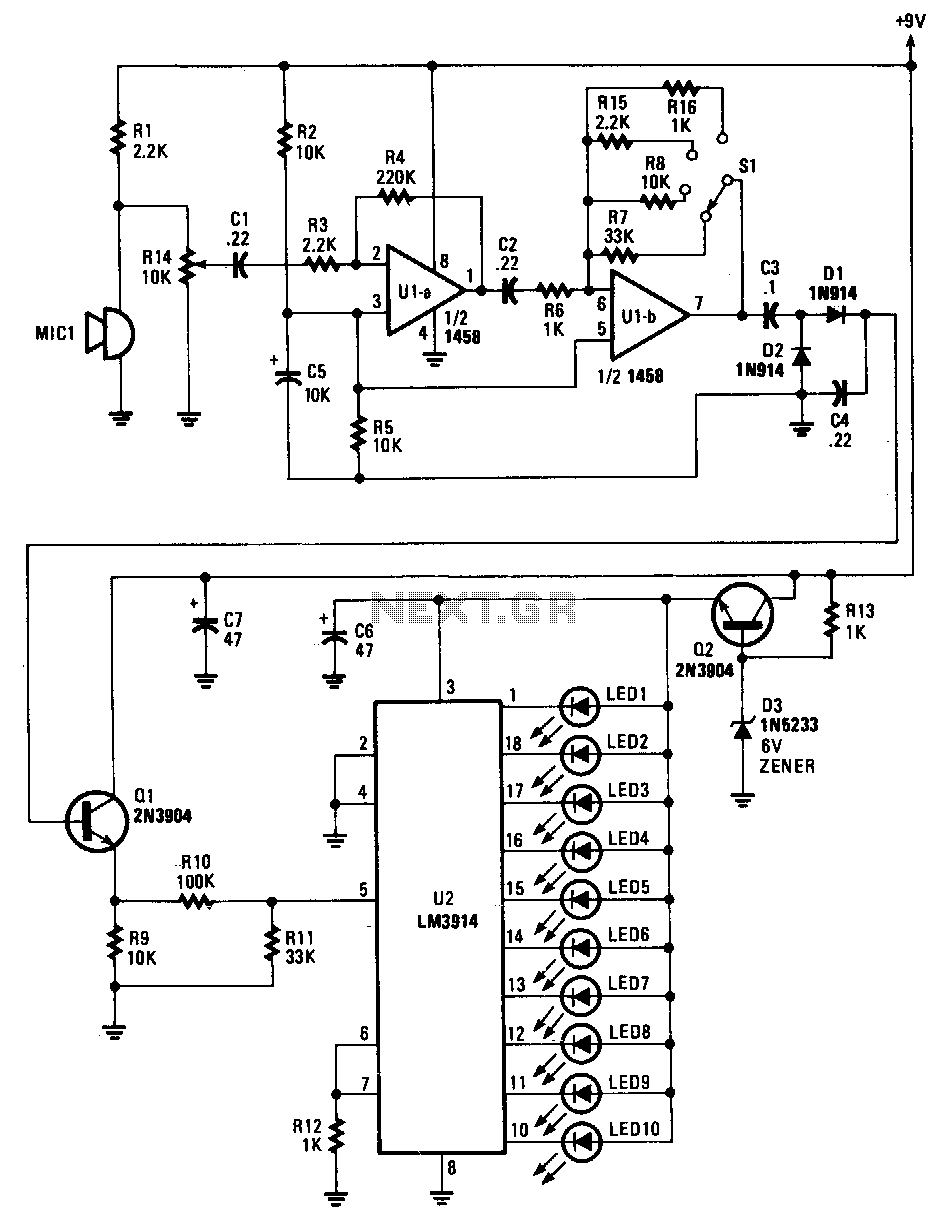

This document is a revised version of an article titled "Better Bachmann Sound For Under A Buck," which was published in the February 1998 issue of Garden Railways Magazine. It does not include editorial changes or additional artwork that may have been added by Garden Railways. The Bachmann Big Hauler locomotive has seen significant improvements in appearance, reliability, and noise levels over the years. However, the basic sound system remains unchanged. The system produces a poor imitation of exhaust sound, represented by a "chuff" synchronized with the engine drivers. Although it cannot match the quality of modern digital sound systems, enhancements can be made for less than a dollar in parts and a few minutes of labor. The unmodified sound system has a sharp exhaust sound profile. By adding one resistor and one capacitor to the sound board in the tender, the attack and delay of the exhaust beat can be softened. The system's frequency response results in a tinny sound, which can be improved with two additional components to enhance the low-frequency response. The sound system generates only two beats per driver revolution, while real steam locomotives produce four. Adding two short wires or resistors to the sound drum on the front axle of the locomotive can provide the additional beats. The system sometimes produces a continuous hiss when it stops with the sound contacts closed. A simple track power sensor can be used to disable the sound when track power is lost. Each of these modifications can be made independently and are completely reversible. These enhancements significantly improve the Bachmann Big Hauler, and such modifications should be considered for future models. Real steam locomotives often produce beats of varying amplitude during forward and backward piston strokes. This can result from the engineer adjusting valve timing or from worn valves and other issues, leading to a "CHUFF CHUFF chuff chuff" sound sequence. While this variable exhaust sound is not constant, it adds interest compared to steady exhaust sounds. Such sound sequences, or any repeating four-pulse beat, can also be achieved through simple and reversible modifications to the sound drum. The sound generator circuit board is located in the tender of the locomotive. A schematic diagram of the circuit is provided. The circuit features a noise diode and a high-gain amplifier to drive the speaker. The sound system is activated and deactivated by the sound drum in the locomotive, which connects or disconnects a tender-mounted 9-volt battery. For RC Big Haulers, the switched 9-volt power is sourced from the locomotive battery. The described modifications are applicable to both versions. In the RC Big Hauler, the sound circuit is integrated into the motor controller board located in the engine smokebox. The circuit is identical and occupies the rear third of the circuit board. Access to the sound board can be obtained by removing the four screws on the bottom of the tender that secure the tender body, followed by removing the two screws that attach the coal load, which can be set aside for later reinstallation. The coal load will remain in place when the tender body is reattached. The modifications are easier to perform with the tender body installed, as it also serves as the battery holder. The black wire leading to the locomotive should be located; it connects to a pad on the board that also has a white wire leading to the battery. Unsolder the black wire and install one end of a 10 to 22-ohm resistor.

The circuit modifications proposed for the Bachmann Big Hauler sound system focus on enhancing the audio output quality and functionality. The addition of a resistor and capacitor to the sound board in the tender will significantly alter the characteristics of the exhaust sound, making it more realistic by softening the initial attack and extending the decay of the sound. This modification addresses the sharpness of the unmodified sound profile.

Furthermore, the introduction of additional components aimed at improving the low-frequency response is essential for achieving a fuller sound. The original sound system's limitation of generating only two beats per driver revolution can be effectively remedied by connecting extra wires or resistors to the sound drum, allowing it to mimic the authentic four exhaust beats of actual steam locomotives. This not only enhances the auditory experience but also adds to the realism of the locomotive's operation.

To prevent the sound system from producing unwanted noise when the locomotive stops, the integration of a track power sensor is recommended. This sensor will automatically deactivate the sound system when power is lost, eliminating the persistent hiss that can occur with the sound contacts closed.

The modifications are designed to be independent and reversible, allowing for easy implementation without permanent alterations to the original circuit. This flexibility is crucial for hobbyists who may wish to restore the system to its original state. The overall aim of these enhancements is to provide an improved auditory experience for users of the Bachmann Big Hauler, making it a more enjoyable model for enthusiasts and collectors alike. The detailed schematic diagram, which includes the noise diode and high-gain amplifier, serves as a guide for those undertaking these modifications, ensuring that the installation process is straightforward and effective.This page is a revised version of the original submission of an article entitled "Better Bachmann Sound For Under A Buck" published in the Feb. 1998 issue of Garden Railways Magazine. Editorial changes and additional artwork that might have been added by Garden Railways are not included in this document.

The Bachmann Big Hauler locomotive has impr oved greatly over the last few years in appearance, reliability and noise level. However one thing that hasn`t improved is the very basic sound system. The system provides a pretty poor facsimile of an exhaust sound in the form of a "chuff" that is synchronized to the engine drivers. The system can`t provide anything near the pleasing sound of new digital sound systems, but for less than a dollar`s worth of parts and a few minutes labor, the sound can be materially improved.

The "profile" of the exhaust sound is much too sharp in an unmodified sound system. Addition of one resistor and one capacitor to the sound board in the tender will soften the attack and delay of the exhaust beat. The frequency response of the system leads to a tinny sound, two more parts can improve the low frequency response.

The sound system generates only two beats per driver revolution while real steam locomotives have four exhaust beats per revolution. Addition of two short wires or resistors to the sound drum on the front axle in the locomotive adds the other two beats.

The system has the annoying tendency to sometimes hiss continuously when it stops with the sound contacts closed. A simple track power sensor can shut it off when the track power goes away. Each of these changes can be made independently and all are completely reversible. I find that the addition of these simple modifications makes a material improvement to the Bachmann Big Hauler, ones that Bachmann should incorporate in some future model.

Often real steam locomotives will generate beats of different amplitude on the forward and backward piston strokes. This is sometimes caused by the engineer adjusting the valve timing to modify locomotive performance, especially at low speeds, but more often it is caused by a tired and worn valves or a number of other problems.

This can result in a "CHUFF CHUFF chuff chuff" sound sequence. While this variable exhaust sound usually doesn`t happen all the time, it is more interesting than steady and unchanging exhaust sounds. This sound sequence, or any other repeating four pulse beat can also be accommodated by simple and reversible modifications to the sound drum.

The sound generator circuit board sits in the tender of the locomotive. A schematic diagram of the circuit is shown below. The circuit consists of a noise diode and a high gain amplifier to drive the speaker. The sound system is switched on and off by the sound drum in the locomotive which either connects or disconnects a tender mounted 9 volt battery. On RC Big Haulers, switched 9 volt power comes from the locomotive battery. The modifications described here will work for either version. In the RC Big Hauler, the sound circuit is part of the motor controller board in the engine smokebox.

The circuit is the same and it occupies the rearmost third of the circuit board. Gain access the sound board by removing the four screws on the bottom of the tender that hold on the tender body and then remove the body. Remove the two screws that attach the coal load and drop the screws into your junk box. The coal load will stay in place by itself when you reinstall it later. Reinstall the tender body and work through the hole exposed by the removed coal load. Its actually easier to do this mod with the tender body installed because the tender body is the battery holder too.

Locate the black wire that leads to the locomotive as shown in the photo. It should go a pad on the board that also has a white wire leading to the battery. Unsolder the black wire. Install one end of a 10 to 22 ohm resistor a 🔗 External reference

The circuit modifications proposed for the Bachmann Big Hauler sound system focus on enhancing the audio output quality and functionality. The addition of a resistor and capacitor to the sound board in the tender will significantly alter the characteristics of the exhaust sound, making it more realistic by softening the initial attack and extending the decay of the sound. This modification addresses the sharpness of the unmodified sound profile.

Furthermore, the introduction of additional components aimed at improving the low-frequency response is essential for achieving a fuller sound. The original sound system's limitation of generating only two beats per driver revolution can be effectively remedied by connecting extra wires or resistors to the sound drum, allowing it to mimic the authentic four exhaust beats of actual steam locomotives. This not only enhances the auditory experience but also adds to the realism of the locomotive's operation.

To prevent the sound system from producing unwanted noise when the locomotive stops, the integration of a track power sensor is recommended. This sensor will automatically deactivate the sound system when power is lost, eliminating the persistent hiss that can occur with the sound contacts closed.

The modifications are designed to be independent and reversible, allowing for easy implementation without permanent alterations to the original circuit. This flexibility is crucial for hobbyists who may wish to restore the system to its original state. The overall aim of these enhancements is to provide an improved auditory experience for users of the Bachmann Big Hauler, making it a more enjoyable model for enthusiasts and collectors alike. The detailed schematic diagram, which includes the noise diode and high-gain amplifier, serves as a guide for those undertaking these modifications, ensuring that the installation process is straightforward and effective.This page is a revised version of the original submission of an article entitled "Better Bachmann Sound For Under A Buck" published in the Feb. 1998 issue of Garden Railways Magazine. Editorial changes and additional artwork that might have been added by Garden Railways are not included in this document.

The Bachmann Big Hauler locomotive has impr oved greatly over the last few years in appearance, reliability and noise level. However one thing that hasn`t improved is the very basic sound system. The system provides a pretty poor facsimile of an exhaust sound in the form of a "chuff" that is synchronized to the engine drivers. The system can`t provide anything near the pleasing sound of new digital sound systems, but for less than a dollar`s worth of parts and a few minutes labor, the sound can be materially improved.

The "profile" of the exhaust sound is much too sharp in an unmodified sound system. Addition of one resistor and one capacitor to the sound board in the tender will soften the attack and delay of the exhaust beat. The frequency response of the system leads to a tinny sound, two more parts can improve the low frequency response.

The sound system generates only two beats per driver revolution while real steam locomotives have four exhaust beats per revolution. Addition of two short wires or resistors to the sound drum on the front axle in the locomotive adds the other two beats.

The system has the annoying tendency to sometimes hiss continuously when it stops with the sound contacts closed. A simple track power sensor can shut it off when the track power goes away. Each of these changes can be made independently and all are completely reversible. I find that the addition of these simple modifications makes a material improvement to the Bachmann Big Hauler, ones that Bachmann should incorporate in some future model.

Often real steam locomotives will generate beats of different amplitude on the forward and backward piston strokes. This is sometimes caused by the engineer adjusting the valve timing to modify locomotive performance, especially at low speeds, but more often it is caused by a tired and worn valves or a number of other problems.

This can result in a "CHUFF CHUFF chuff chuff" sound sequence. While this variable exhaust sound usually doesn`t happen all the time, it is more interesting than steady and unchanging exhaust sounds. This sound sequence, or any other repeating four pulse beat can also be accommodated by simple and reversible modifications to the sound drum.

The sound generator circuit board sits in the tender of the locomotive. A schematic diagram of the circuit is shown below. The circuit consists of a noise diode and a high gain amplifier to drive the speaker. The sound system is switched on and off by the sound drum in the locomotive which either connects or disconnects a tender mounted 9 volt battery. On RC Big Haulers, switched 9 volt power comes from the locomotive battery. The modifications described here will work for either version. In the RC Big Hauler, the sound circuit is part of the motor controller board in the engine smokebox.

The circuit is the same and it occupies the rearmost third of the circuit board. Gain access the sound board by removing the four screws on the bottom of the tender that hold on the tender body and then remove the body. Remove the two screws that attach the coal load and drop the screws into your junk box. The coal load will stay in place by itself when you reinstall it later. Reinstall the tender body and work through the hole exposed by the removed coal load. Its actually easier to do this mod with the tender body installed because the tender body is the battery holder too.

Locate the black wire that leads to the locomotive as shown in the photo. It should go a pad on the board that also has a white wire leading to the battery. Unsolder the black wire. Install one end of a 10 to 22 ohm resistor a 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713