Car & Motorcycle Battery Tester

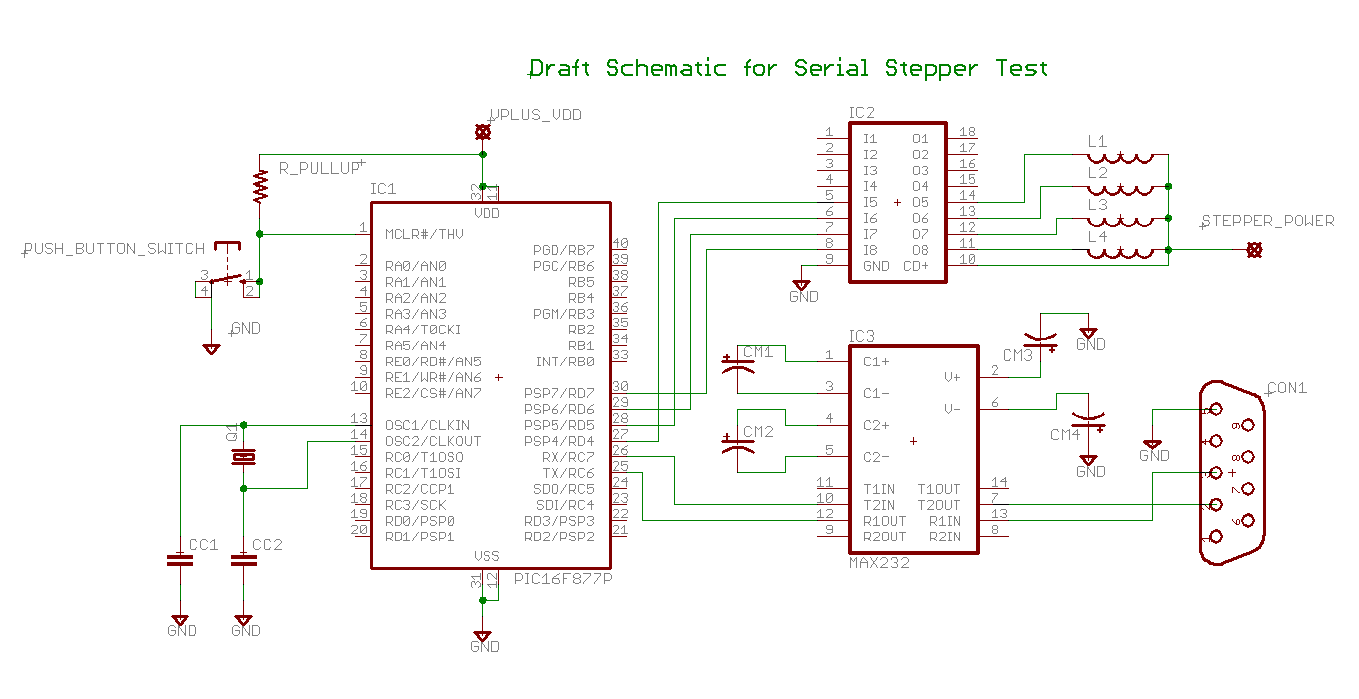

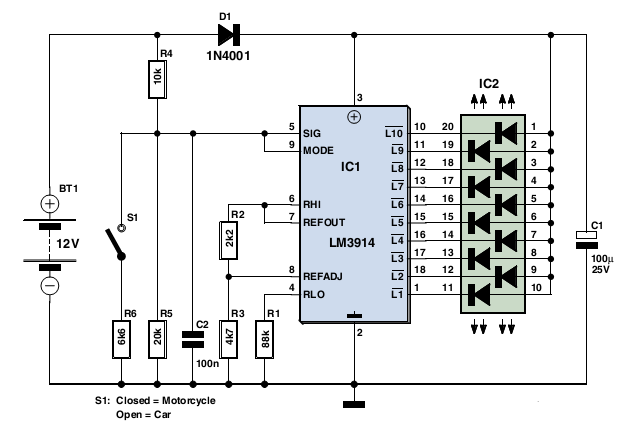

Typically, a charged lead-acid battery and a power inverter are utilized to ensure a well-organized holiday where family members can enjoy their electric and electronic devices. With rechargeable lead-acid batteries, it is often beneficial, if not essential, to determine whether the power source being transported during travels is losing capacity and requires recharging. Additionally, the same circuit can be useful for checking the status of a 12 V (car) or a 6 V (motorcycle) battery during car or motorbike trips. The circuit draws minimal power, ensuring it does not significantly load the battery under test, although it should not be left connected permanently. The circuit utilizes the LM3914 (IC1) to display the voltage level, providing a battery status readout: when the top LED lights up, the battery is fully charged, and when the bottom LED lights up, the battery requires immediate charging. A switch (S1) allows selection between 12 V and 6 V operation. A series diode (D1) safeguards the bargraph driver from reverse supply voltage. For improved indication of the battery's state, a color-coded display with individual LEDs could be employed instead of the common anode bargraph display.

The described circuit serves as a voltage monitoring system for lead-acid batteries, specifically designed for portable applications such as holiday trips or vehicle excursions. The use of the LM3914 integrated circuit enables a straightforward visual representation of battery voltage levels through a series of LED indicators.

The circuit operates by connecting the battery under test to the appropriate input terminals, which are determined by the position of switch S1. This switch allows the user to toggle between the 12 V and 6 V settings, accommodating different battery types commonly found in vehicles. When the circuit is powered, the LM3914 reads the input voltage and activates the corresponding number of LEDs based on the voltage level detected. The top LED indicates a fully charged battery, while the bottom LED signals that the battery is critically low and needs charging.

Incorporating diode D1 into the design is crucial for protecting the LM3914 from potential damage due to reverse polarity connections, which can occur if the battery is connected incorrectly. This safeguard ensures the longevity and reliability of the circuit.

For enhanced functionality, the circuit could be modified to incorporate a color-coded LED array, where each LED represents a specific voltage range. This would provide users with a more intuitive understanding of the battery's status at a glance, rather than relying solely on the position of the lit LED in a bargraph format.

Overall, this battery status monitoring circuit is a practical solution for anyone relying on lead-acid batteries during travel, ensuring that users can easily ascertain the battery's condition and take necessary actions to maintain their power supply.Most of the time a charged lead-acid battery and a power inverter would be used to ensure a smoothly organised holiday where ideally the missus and the children cheerfully use their electric and electronic gear! With rechargeable lead-acid batteries it`s invariably useful if not essential to determine whether the power source you`re hauling along on your travels is losing capacity and needs to be topped up.

The same circuit would also come in handy when going on a car or motorbike trip as it can check the status of a 12 V (car) or a 6 V (motorcycle) battery. Although the circuit draws so little power that it will not notice-ably load the battery under test, it should not be left connected permanently.

The circuit employs the familiar LM3914 (IC1) to display the voltage level. The LED readout creates a battery status readout: when the top LED lights, the battery is fully charged. When the bottom LED lights, the battery needs imminent charging! Switch S1 selects between 12 V and 6 V operation. A series diode, D1, protects the bargraph driver from reverse supply volt-age. A colour coded display with individual LEDs could be used instead of the common anode bargraph display for better indication of the state of the battery.

🔗 External reference

The described circuit serves as a voltage monitoring system for lead-acid batteries, specifically designed for portable applications such as holiday trips or vehicle excursions. The use of the LM3914 integrated circuit enables a straightforward visual representation of battery voltage levels through a series of LED indicators.

The circuit operates by connecting the battery under test to the appropriate input terminals, which are determined by the position of switch S1. This switch allows the user to toggle between the 12 V and 6 V settings, accommodating different battery types commonly found in vehicles. When the circuit is powered, the LM3914 reads the input voltage and activates the corresponding number of LEDs based on the voltage level detected. The top LED indicates a fully charged battery, while the bottom LED signals that the battery is critically low and needs charging.

Incorporating diode D1 into the design is crucial for protecting the LM3914 from potential damage due to reverse polarity connections, which can occur if the battery is connected incorrectly. This safeguard ensures the longevity and reliability of the circuit.

For enhanced functionality, the circuit could be modified to incorporate a color-coded LED array, where each LED represents a specific voltage range. This would provide users with a more intuitive understanding of the battery's status at a glance, rather than relying solely on the position of the lit LED in a bargraph format.

Overall, this battery status monitoring circuit is a practical solution for anyone relying on lead-acid batteries during travel, ensuring that users can easily ascertain the battery's condition and take necessary actions to maintain their power supply.Most of the time a charged lead-acid battery and a power inverter would be used to ensure a smoothly organised holiday where ideally the missus and the children cheerfully use their electric and electronic gear! With rechargeable lead-acid batteries it`s invariably useful if not essential to determine whether the power source you`re hauling along on your travels is losing capacity and needs to be topped up.

The same circuit would also come in handy when going on a car or motorbike trip as it can check the status of a 12 V (car) or a 6 V (motorcycle) battery. Although the circuit draws so little power that it will not notice-ably load the battery under test, it should not be left connected permanently.

The circuit employs the familiar LM3914 (IC1) to display the voltage level. The LED readout creates a battery status readout: when the top LED lights, the battery is fully charged. When the bottom LED lights, the battery needs imminent charging! Switch S1 selects between 12 V and 6 V operation. A series diode, D1, protects the bargraph driver from reverse supply volt-age. A colour coded display with individual LEDs could be used instead of the common anode bargraph display for better indication of the state of the battery.

🔗 External reference