charging circuit

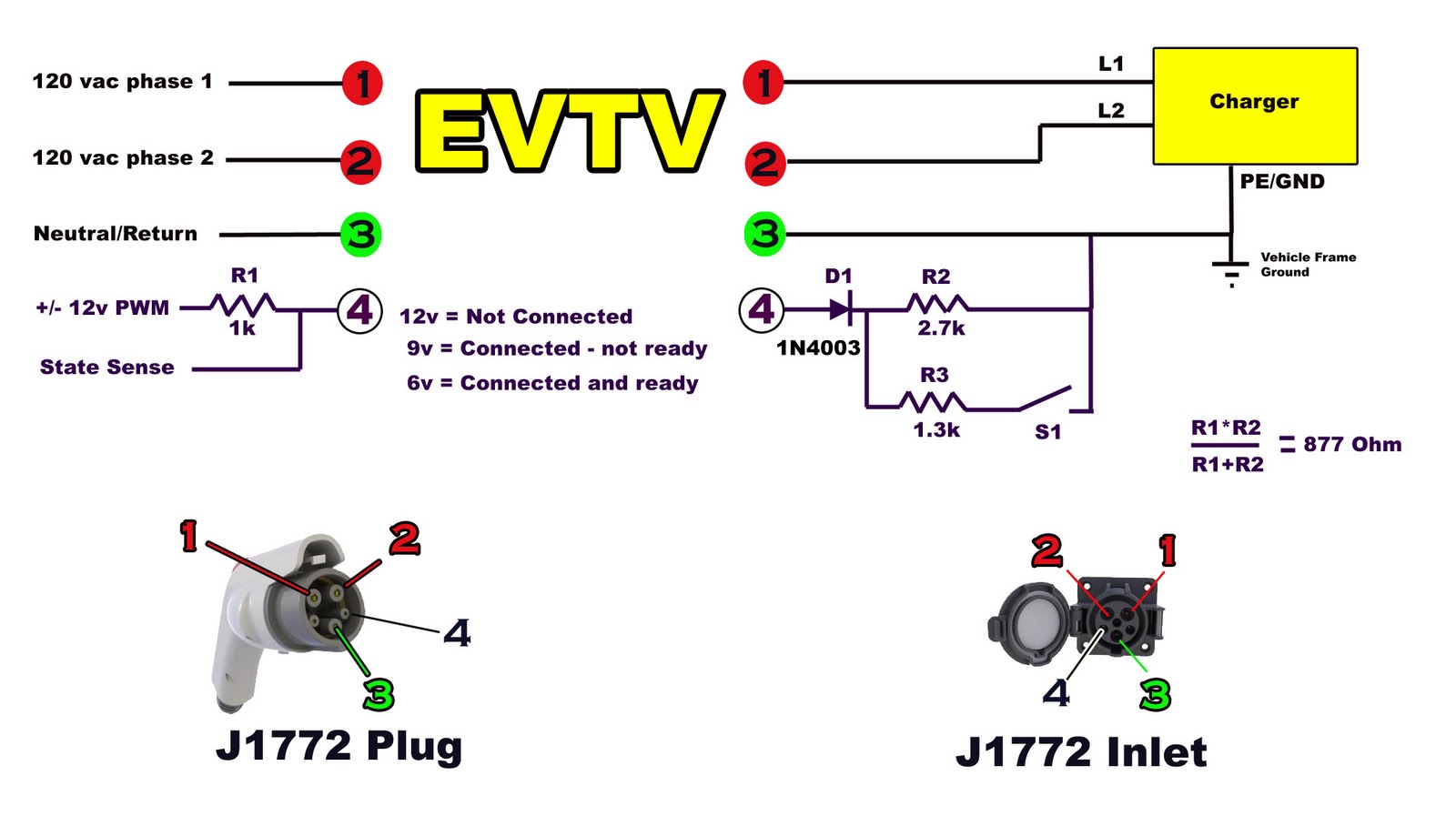

Building battery boxes for the Speedster. Although this topic may not seem thrilling, builders converting vehicles to electric drive often discover that the process of making a car run on battery power is relatively straightforward. However, about 50% of the effort is focused on positioning the batteries and constructing the necessary support structures. To make this discussion more engaging, the focus will shift to a useful aspect promised nearly a year ago during an episode on the J1772-2009 standard, plugs, and connectors. This involves wiring the car for J1772 charging. With the Chevy Volt and Nissan Leaf now available, the appearance of J1772 charging stations is anticipated. The vehicles are designed to charge automatically from either 120VAC single-phase or 240VAC two-phase power. Typically, a NEMA 5-15 recessed male connector is utilized on the vehicle to enable universal connectivity with standard household extension cables, although a heavy-duty cable is recommended. This practice is technically illegal, as the NEMA 5-15 connector is intended for 120VAC operation at 15 amperes or less. In reality, the Speedsters are charged at approximately 25 amperes and 240VAC. An adapter is often created with a NEMA L6-30 or NEMA 14-50 connector on one end and a standard NEMA 5-15 female connector on the other. While this approach is convenient, it poses safety concerns. When J1772 charging stations become more prevalent, there will be a disadvantage for those not equipped with the standard. The exclusivity surrounding the "standard" raises questions, particularly as charging station vendors seek to maintain high profit margins, with prices reaching as high as $5000 for what is essentially an AC receptacle. The standard does incorporate safety features to ensure the cord remains inactive until properly connected, and the quality of the plugs and connectors is commendable. However, the basic connector hardware remains elusive nearly a year post-adoption. The SAE has also been criticized for its restrictive practices concerning the J1772-2009 PDF, which is only available for purchase on their website with stringent copyright warnings. This situation reflects a broader issue of control over charging stations and inflated profit margins. The cost of connectors can range from a couple of hundred dollars depending on the cable type and length, yet the pricing for installation remains unjustifiable. The requirement for licensed electricians and permits for installation is often seen as excessive, especially since some systems simply plug into existing NEMA receptacles, similar to the DIY approach. For those willing to undertake the task, adding a 60-amp or 100-amp circuit breaker to a home panel and running AWG10 orange 3-wire plus ground to a garage is a feasible and safe project. Many resources are available for home wiring at local hardware stores, including wire, NEMA receptacles, and circuit breakers. In most jurisdictions, individuals can legally perform such wiring in their residences without needing a license or permit. Regarding the vehicle, installing a J1772-2009 inlet connector on the car and connecting the two-phase pins along with the ground pin is the next step.

The construction of battery boxes for electric vehicles, such as the Speedster, is a crucial aspect of the conversion process. These battery boxes must be designed to securely hold the batteries in place while also allowing for efficient thermal management and accessibility for maintenance. The design considerations include the material selection for the boxes, which should be lightweight yet sturdy enough to withstand vibrations and impacts during vehicle operation. Common materials used for battery enclosures include aluminum, steel, or high-strength plastics, each offering different benefits in terms of weight, cost, and durability.

The layout of the battery boxes must also account for the weight distribution of the vehicle to ensure optimal handling and stability. Proper placement of the batteries can significantly influence the center of gravity, which is particularly important for electric vehicles that may have a different weight distribution compared to their internal combustion counterparts. Additionally, the boxes should include provisions for securing the batteries to prevent movement during operation, as well as features for ventilation to manage heat generated during charging and discharging cycles.

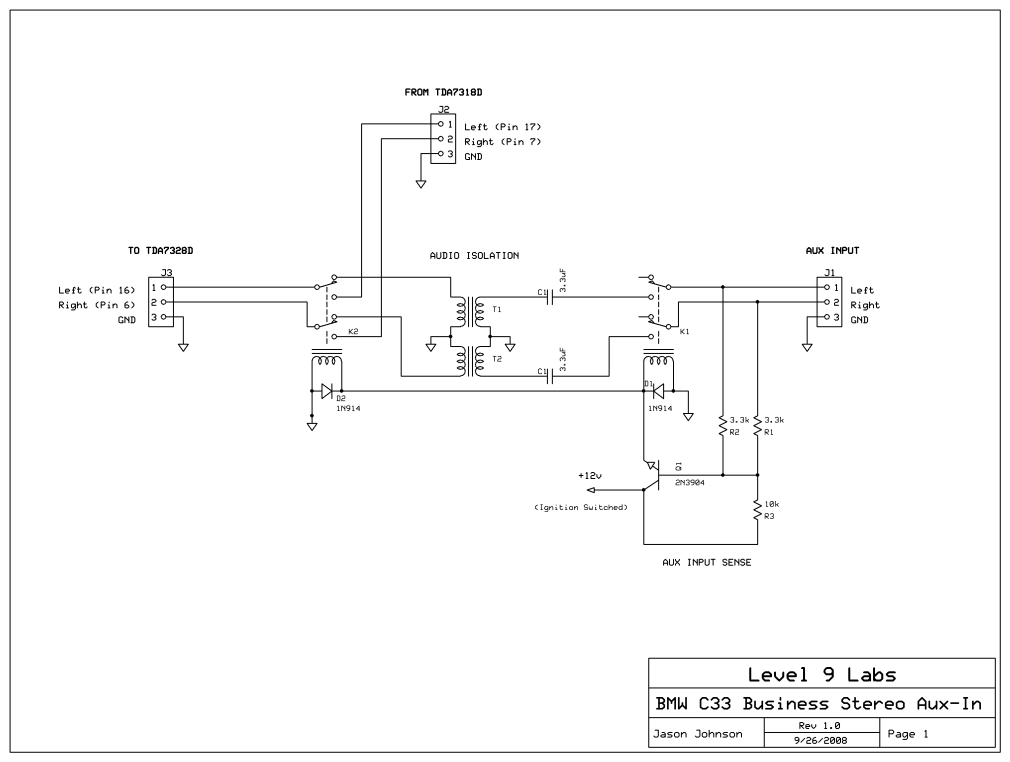

The integration of J1772 charging capabilities into the vehicle's design necessitates careful planning of the electrical system. The J1772 connector serves as the interface between the electric vehicle and the charging station, and it is essential to ensure that the wiring and components used in this system are rated for the expected current and voltage levels. The incorporation of a J1772 inlet connector requires the use of appropriate gauge wiring to handle the charging current safely, along with circuit protection devices such as fuses or circuit breakers to prevent overload conditions.

Furthermore, the charging system should be equipped with safety features that comply with the J1772 standard, including ground fault protection and interlock mechanisms that prevent the vehicle from charging unless the connector is securely attached. These safety measures are critical not only for the protection of the vehicle's electrical system but also for the safety of users and the public.

In summary, the construction of battery boxes for electric vehicles involves a multifaceted approach that encompasses structural integrity, weight distribution, thermal management, and compliance with charging standards. By addressing these considerations, builders can create a robust and functional electric vehicle capable of efficient operation and safe charging.Building battery boxes for the Speedster. While not an exciting topic, in converting almost any car to electric drive, most new builders are surprised to learn that making the car run on battery power is almost trivial. But 50% of the work centers on placing batteries and building structures to hold them. So to avoid making this episode a total yawnfest, we`ve decided to tackle a probably useful element we

promised almost a year ago when we did our episode on the new J1772-2009 standard/plugs/connectors. That is, how to wire your car to actually do J1772 charging. With the Chevy Volt and the Nissan Leaf finally shipping. er. more or less shipping. we think you`ll finally begin to see some J1772 charging stations begin to appear. We build our cars to charge quite automatically from either 120VAC single phase or 240vac two phase power. And we almost always use a NEMA 5-15 recessed male connector on the car so that we can universally connect the car anywhere and to virtually any ordinary household extension cable - albeit you do generally want to use a heavy one.

This is mildly illegal in most respects. First, NEMA5-15 is entirely meant for 120vac operation at 15 amperes or less. In practice, we charge the Speedsters at about 25 amperes and 240vac. We simply make up a cord or "adapter" with a NEMA L6-30 or NEMA 14-50 connector on one end, and the usual NEMA 5-15 female on the other. This is not good frankly. But it is very convenient. If you go to gramma`s house, you can still plug in and get a toke on her good juice, even though there`s no charge station there.

We buy the best cables and connectors we can find, and while they get warm, so far no incidents. But it isn`t really kosher. And soon it will even be a disadvantage. As J1772 charge stations start to appear, at the least in the garages of friends with Nissan Leaf or Chevy Volts, and potentially public charge stations as well, we would be left out of the party. For a "standard" I am perplexed by how "closed" all this is. The greed is palpable as the charge station vendors strive to "protect" their ground so they get prices as high as $5000 for what is little more than an AC receptacle.

The "standard" does provide some safety features to keep the cord dead until it is connected (which I put in our Texaco Fire Chief charge station nearly two years ago). And the plug and connector ARE kind of quality. But it is amazing how difficult it is to find the basic connector hardware - nearly a year after adoption.

Indeed, SAE itself has been piggishly greedy - you can`t find an SAE J1772-2009 PDF online anywhere. They are "selling it" on their web site with digital rights management and dire warnings about copyright infringement. Copyright infringement on a public standards body This is just inexcusable. In any event, there IS a conspiracy to control these charging stations and maintain high profit margins on the charge stations.

The connectors are a couple of hundred dollars each depending on how long and what kind of cable. None of it warrants $5000 or even $2500, I don`t care how many approvals it carries. And the whole concept of having a licensed electrician and permit to install it is laughable. Some of them actually just plug into an existing NEMA receptacle just as we do with our cords. In any event, adding a 60amp or 100 amp circuit breaker to your panel, and running a piece of AWG10 orange 3-wire plus ground to a convenient place in your garage, is work ANYONE can do AND SAFELY. There are numerous home wiring books at the local hardware store, the wire, the NEMA receptacles, and the circuit breakers.

And in almost all localities you are entirely legal to do such wiring ON YOUR OWN RESIDENCE without license or permit. But back to the car. If you buy a J1772-2009 inlet connector and mount it on your car, and connect the two phase pins and the ground pin to your

🔗 External reference

The construction of battery boxes for electric vehicles, such as the Speedster, is a crucial aspect of the conversion process. These battery boxes must be designed to securely hold the batteries in place while also allowing for efficient thermal management and accessibility for maintenance. The design considerations include the material selection for the boxes, which should be lightweight yet sturdy enough to withstand vibrations and impacts during vehicle operation. Common materials used for battery enclosures include aluminum, steel, or high-strength plastics, each offering different benefits in terms of weight, cost, and durability.

The layout of the battery boxes must also account for the weight distribution of the vehicle to ensure optimal handling and stability. Proper placement of the batteries can significantly influence the center of gravity, which is particularly important for electric vehicles that may have a different weight distribution compared to their internal combustion counterparts. Additionally, the boxes should include provisions for securing the batteries to prevent movement during operation, as well as features for ventilation to manage heat generated during charging and discharging cycles.

The integration of J1772 charging capabilities into the vehicle's design necessitates careful planning of the electrical system. The J1772 connector serves as the interface between the electric vehicle and the charging station, and it is essential to ensure that the wiring and components used in this system are rated for the expected current and voltage levels. The incorporation of a J1772 inlet connector requires the use of appropriate gauge wiring to handle the charging current safely, along with circuit protection devices such as fuses or circuit breakers to prevent overload conditions.

Furthermore, the charging system should be equipped with safety features that comply with the J1772 standard, including ground fault protection and interlock mechanisms that prevent the vehicle from charging unless the connector is securely attached. These safety measures are critical not only for the protection of the vehicle's electrical system but also for the safety of users and the public.

In summary, the construction of battery boxes for electric vehicles involves a multifaceted approach that encompasses structural integrity, weight distribution, thermal management, and compliance with charging standards. By addressing these considerations, builders can create a robust and functional electric vehicle capable of efficient operation and safe charging.Building battery boxes for the Speedster. While not an exciting topic, in converting almost any car to electric drive, most new builders are surprised to learn that making the car run on battery power is almost trivial. But 50% of the work centers on placing batteries and building structures to hold them. So to avoid making this episode a total yawnfest, we`ve decided to tackle a probably useful element we

promised almost a year ago when we did our episode on the new J1772-2009 standard/plugs/connectors. That is, how to wire your car to actually do J1772 charging. With the Chevy Volt and the Nissan Leaf finally shipping. er. more or less shipping. we think you`ll finally begin to see some J1772 charging stations begin to appear. We build our cars to charge quite automatically from either 120VAC single phase or 240vac two phase power. And we almost always use a NEMA 5-15 recessed male connector on the car so that we can universally connect the car anywhere and to virtually any ordinary household extension cable - albeit you do generally want to use a heavy one.

This is mildly illegal in most respects. First, NEMA5-15 is entirely meant for 120vac operation at 15 amperes or less. In practice, we charge the Speedsters at about 25 amperes and 240vac. We simply make up a cord or "adapter" with a NEMA L6-30 or NEMA 14-50 connector on one end, and the usual NEMA 5-15 female on the other. This is not good frankly. But it is very convenient. If you go to gramma`s house, you can still plug in and get a toke on her good juice, even though there`s no charge station there.

We buy the best cables and connectors we can find, and while they get warm, so far no incidents. But it isn`t really kosher. And soon it will even be a disadvantage. As J1772 charge stations start to appear, at the least in the garages of friends with Nissan Leaf or Chevy Volts, and potentially public charge stations as well, we would be left out of the party. For a "standard" I am perplexed by how "closed" all this is. The greed is palpable as the charge station vendors strive to "protect" their ground so they get prices as high as $5000 for what is little more than an AC receptacle.

The "standard" does provide some safety features to keep the cord dead until it is connected (which I put in our Texaco Fire Chief charge station nearly two years ago). And the plug and connector ARE kind of quality. But it is amazing how difficult it is to find the basic connector hardware - nearly a year after adoption.

Indeed, SAE itself has been piggishly greedy - you can`t find an SAE J1772-2009 PDF online anywhere. They are "selling it" on their web site with digital rights management and dire warnings about copyright infringement. Copyright infringement on a public standards body This is just inexcusable. In any event, there IS a conspiracy to control these charging stations and maintain high profit margins on the charge stations.

The connectors are a couple of hundred dollars each depending on how long and what kind of cable. None of it warrants $5000 or even $2500, I don`t care how many approvals it carries. And the whole concept of having a licensed electrician and permit to install it is laughable. Some of them actually just plug into an existing NEMA receptacle just as we do with our cords. In any event, adding a 60amp or 100 amp circuit breaker to your panel, and running a piece of AWG10 orange 3-wire plus ground to a convenient place in your garage, is work ANYONE can do AND SAFELY. There are numerous home wiring books at the local hardware store, the wire, the NEMA receptacles, and the circuit breakers.

And in almost all localities you are entirely legal to do such wiring ON YOUR OWN RESIDENCE without license or permit. But back to the car. If you buy a J1772-2009 inlet connector and mount it on your car, and connect the two phase pins and the ground pin to your

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713