control relay with infrared circuit

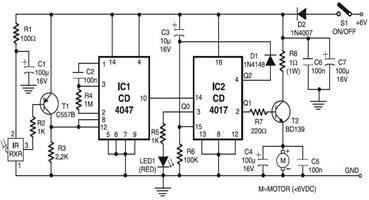

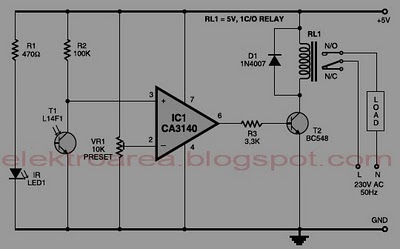

Typically, home appliances are controlled using switches, sensors, and similar devices. However, physical interaction with switches can pose safety risks in the event of a short circuit. The circuit outlined here eliminates the need for physical contact to operate appliances. It operates by detecting hand movement between an infrared LED (IR LED1) and a phototransistor (T1). The infrared rays emitted by IR LED1 are detected by the phototransistor, which activates devices such as hidden locks, flush systems, or hand dryers. This circuit is notably stable and sensitive when compared to other AC appliance control circuits. It is designed to be simple, compact, and cost-effective, with low current consumption in the milliamperes range. The circuit comprises an IC CA3140, IR LED1, a phototransistor, and various discrete components. When a regulated 5V power supply is connected, IR LED1 emits infrared rays that are received by phototransistor T1, provided they are properly aligned. The collector of T1 connects to the non-inverting pin (pin 3) of IC1. The inverting pin (pin 2) of IC1 is linked to a voltage-divider preset (VR1), allowing for adjustment of the reference voltage at pin 2, which in turn influences the sensitivity of the phototransistor. The operational amplifier IC1 amplifies the signal received from the phototransistor. A resistor (R3) is used to control the base current of transistor BC548 (T2). The high output from IC1 at pin 6 activates transistor T2, which energizes relay RL1 to turn on the appliance, such as a hand dryer, through the relay contacts. The operation of the circuit is straightforward.

The circuit operates on the principle of infrared light detection, providing a touchless control mechanism for various appliances. The IR LED1 continuously emits infrared light, which is typically invisible to the human eye. When a hand moves within the detection range, it interrupts the infrared beam, causing a change in the light intensity received by the phototransistor T1. This change is detected and processed by the operational amplifier (IC1), which is configured as a comparator. The output from IC1 is determined by the voltage levels at its inverting and non-inverting inputs.

The sensitivity of the circuit can be fine-tuned using the voltage-divider preset (VR1). Adjusting VR1 modifies the reference voltage at pin 2 of IC1, allowing for calibration based on environmental conditions or specific application requirements. This feature ensures that the circuit can adapt to varying levels of ambient light or distance of the hand from the IR LED1.

The transistor BC548 (T2) acts as a switch that controls the relay (RL1). When the output from IC1 goes high, it turns on T2, allowing current to flow through the relay coil. This energizes the relay, which closes its contacts and completes the circuit to the connected appliance. The relay serves as an isolating mechanism, ensuring that the low-power control circuit does not directly handle the high voltage of the appliance.

Overall, this circuit design provides a safe, efficient, and user-friendly solution for operating home appliances without the need for direct contact, significantly reducing the risk of electrical hazards.Normally, home appliances are controlled by means of switches, sensors, etc. However, physical contact with switches may be dangerous if there is any shorting. The circuit described here requires no physical contact for operating the appliance. You just need to move your hand between the infrared LED (IR LED1) and the phototransistor (T1). The inf rared rays transmitted by IR LED1 is detected by the phototransistor to activate the hidden lock, flush system, hand dryer or else. This circuit is very stable and sensitive compared to other AC appliance control circuits. It is simple, compact and cheap. Current consumption is low in milliamperes. The circuit is built around an IC CA3140, IRLED1, phototransistor and other discrete components. When regu lated 5V is connected to the circuit, IR LED1 emits infrared rays, which are received by phototransistor T1 if it is properly aligned.

The collector of T1 is connected to non-inverting pin 3 of IC1. Inverting pin 2 of IC1 is connected to voltage-divider preset VR1. Using preset VR1 you can vary the reference voltage at pin 2, which also affects sensitivity of the phototransistor. Op-amp IC1 amplifies the signal received from the phototransistor. Resistor R3 controls the base current of transistor BC548 (T2). The high output of IC1 at pin 6 drives transistor T2 to energise relay RL1 and switch on the appliance, say, hand dryer, through the relay contacts.

The working of the circuit is simple. 🔗 External reference

The circuit operates on the principle of infrared light detection, providing a touchless control mechanism for various appliances. The IR LED1 continuously emits infrared light, which is typically invisible to the human eye. When a hand moves within the detection range, it interrupts the infrared beam, causing a change in the light intensity received by the phototransistor T1. This change is detected and processed by the operational amplifier (IC1), which is configured as a comparator. The output from IC1 is determined by the voltage levels at its inverting and non-inverting inputs.

The sensitivity of the circuit can be fine-tuned using the voltage-divider preset (VR1). Adjusting VR1 modifies the reference voltage at pin 2 of IC1, allowing for calibration based on environmental conditions or specific application requirements. This feature ensures that the circuit can adapt to varying levels of ambient light or distance of the hand from the IR LED1.

The transistor BC548 (T2) acts as a switch that controls the relay (RL1). When the output from IC1 goes high, it turns on T2, allowing current to flow through the relay coil. This energizes the relay, which closes its contacts and completes the circuit to the connected appliance. The relay serves as an isolating mechanism, ensuring that the low-power control circuit does not directly handle the high voltage of the appliance.

Overall, this circuit design provides a safe, efficient, and user-friendly solution for operating home appliances without the need for direct contact, significantly reducing the risk of electrical hazards.Normally, home appliances are controlled by means of switches, sensors, etc. However, physical contact with switches may be dangerous if there is any shorting. The circuit described here requires no physical contact for operating the appliance. You just need to move your hand between the infrared LED (IR LED1) and the phototransistor (T1). The inf rared rays transmitted by IR LED1 is detected by the phototransistor to activate the hidden lock, flush system, hand dryer or else. This circuit is very stable and sensitive compared to other AC appliance control circuits. It is simple, compact and cheap. Current consumption is low in milliamperes. The circuit is built around an IC CA3140, IRLED1, phototransistor and other discrete components. When regu lated 5V is connected to the circuit, IR LED1 emits infrared rays, which are received by phototransistor T1 if it is properly aligned.

The collector of T1 is connected to non-inverting pin 3 of IC1. Inverting pin 2 of IC1 is connected to voltage-divider preset VR1. Using preset VR1 you can vary the reference voltage at pin 2, which also affects sensitivity of the phototransistor. Op-amp IC1 amplifies the signal received from the phototransistor. Resistor R3 controls the base current of transistor BC548 (T2). The high output of IC1 at pin 6 drives transistor T2 to energise relay RL1 and switch on the appliance, say, hand dryer, through the relay contacts.

The working of the circuit is simple. 🔗 External reference