Controller keeps circuits cool

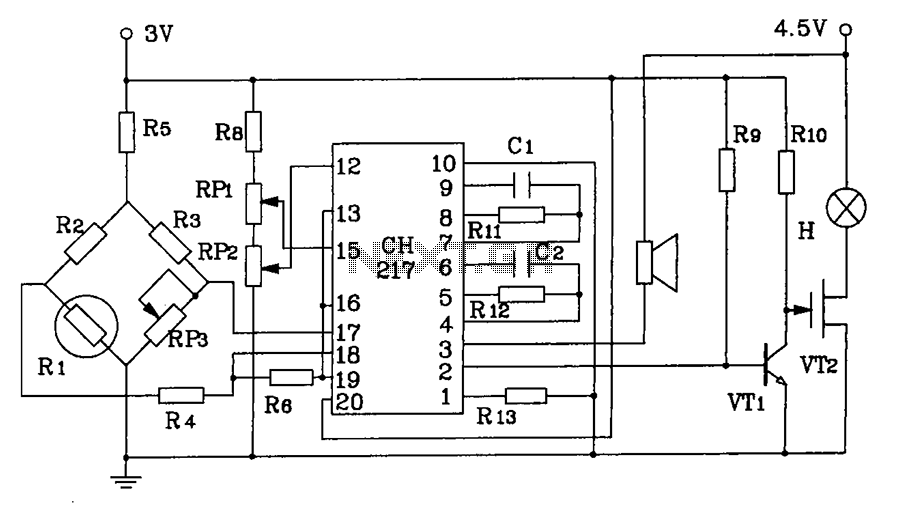

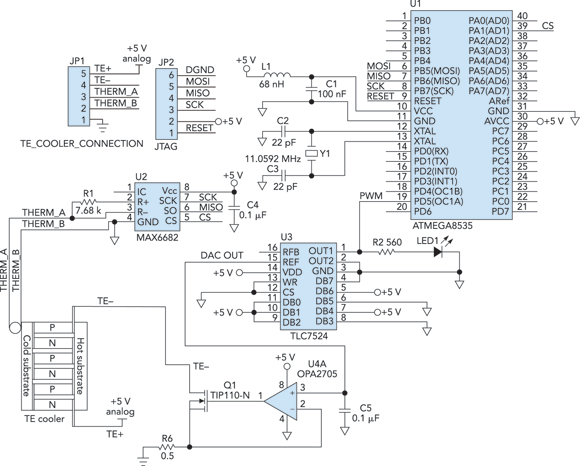

Cooling an instrument or device can enhance the signal-to-noise ratio (SNR) and extend the product's lifespan. For instance, the dark-and-noise signal of an infrared detector's output at room temperature can be significantly reduced when cooled. A custom cooling device was developed as part of a semiconductor study. Figure 1 illustrates the system's block diagram. Figure 2 displays the circuit schematic. The design utilizes a temperature feedback signal to optimize the system's performance. Central to the design is an ATmega8535 microcontroller, which generates a pulse-width modulation (PWM) signal based on temperature measurements. A thermistor-to-digital converter provides a digital output via a three-wire SPI (serial peripheral interface), transmitting data to the microcontroller. A TLC7524 digital-to-analog converter (DAC) produces a control voltage from the PWM signal. This voltage regulates the cooling device through an operational amplifier and a MOSFET (Q1), capable of delivering up to 2 A of control current. The Timer1 code processes the temperature data, averaging 50 measurements, while the Timer2 code compares the measured temperature to the desired temperature setting, adjusting the current to the cooling controller via the microcontroller's PWM output signal.

The cooling system described integrates several key components to achieve effective temperature regulation for sensitive electronic devices. The ATmega8535 microcontroller serves as the central processing unit, executing control algorithms to maintain optimal operating conditions. The PWM signal generated by the microcontroller is critical for modulating the cooling device's power, allowing for fine-tuned adjustments based on real-time temperature feedback.

The thermistor-to-digital converter plays a vital role in translating analog temperature readings into a digital format that the microcontroller can interpret. Utilizing a three-wire SPI interface facilitates efficient communication between the converter and the microcontroller, ensuring timely updates on temperature changes.

The TLC7524 DAC is responsible for converting the PWM signal into a corresponding analog voltage, which is essential for controlling the cooling device's operational state. The operational amplifier amplifies this control voltage, providing the necessary signal strength to drive the MOSFET (Q1). This MOSFET acts as a switch, allowing for the delivery of up to 2 A of current to the cooling system, thus enabling effective thermal management.

Timer1 and Timer2 are integral to the system's functionality. Timer1 is programmed to execute the temperature measurement routine, averaging multiple readings to provide a stable temperature value that mitigates the effects of transient fluctuations. Timer2 continuously monitors the average temperature against a predefined setpoint, dynamically adjusting the PWM output to regulate the cooling power applied to the device.

Overall, this cooling system design exemplifies an effective approach to enhancing the performance and longevity of sensitive electronic instruments through precise temperature control. The integration of microcontroller-based feedback mechanisms and efficient power management components ensures a reliable operation, crucial for applications involving infrared detection and other temperature-sensitive technologies.Cooling an instrument or a device can improve the SNR (signal-to-noise ratio), and it can also prolong product life. For example, the dark-and-noise signal of an infrared detector`s output at room temperature can be an order of magnitude smaller when cooled.

We used the cooling device we built as part of a study of semiconductors. Figure 1 shows the block diagram of the system; Figure 2 ( view Figure 2 ) shows the circuit schematic. The design uses the temperature feedback signal to optimize the system. The heart of the design is an ATmega8535 microcontroller. It produces a PWM (pulse-width modulation) signal based on a temperature measurement. A thermistor-to-digital converter produces a digital output on its three-wire SPI (serial peripheral interface), sending the data to the microcontroller. A TLC7524 DAC (digital-to-analog converter) generates a control voltage from the PWM signal. The voltage controls the cooling device through an op amp and MOSFET (Q1), which can produce up to 2 A of control current.

The Timer1 code reads the temperature data and computes an average value from 50 measurements. The Timer2 code compares the measured temperature to the temperature setting and adjusts the current to the cooling controller through the microcontroller`s PWM output signal. 🔗 External reference

The cooling system described integrates several key components to achieve effective temperature regulation for sensitive electronic devices. The ATmega8535 microcontroller serves as the central processing unit, executing control algorithms to maintain optimal operating conditions. The PWM signal generated by the microcontroller is critical for modulating the cooling device's power, allowing for fine-tuned adjustments based on real-time temperature feedback.

The thermistor-to-digital converter plays a vital role in translating analog temperature readings into a digital format that the microcontroller can interpret. Utilizing a three-wire SPI interface facilitates efficient communication between the converter and the microcontroller, ensuring timely updates on temperature changes.

The TLC7524 DAC is responsible for converting the PWM signal into a corresponding analog voltage, which is essential for controlling the cooling device's operational state. The operational amplifier amplifies this control voltage, providing the necessary signal strength to drive the MOSFET (Q1). This MOSFET acts as a switch, allowing for the delivery of up to 2 A of current to the cooling system, thus enabling effective thermal management.

Timer1 and Timer2 are integral to the system's functionality. Timer1 is programmed to execute the temperature measurement routine, averaging multiple readings to provide a stable temperature value that mitigates the effects of transient fluctuations. Timer2 continuously monitors the average temperature against a predefined setpoint, dynamically adjusting the PWM output to regulate the cooling power applied to the device.

Overall, this cooling system design exemplifies an effective approach to enhancing the performance and longevity of sensitive electronic instruments through precise temperature control. The integration of microcontroller-based feedback mechanisms and efficient power management components ensures a reliable operation, crucial for applications involving infrared detection and other temperature-sensitive technologies.Cooling an instrument or a device can improve the SNR (signal-to-noise ratio), and it can also prolong product life. For example, the dark-and-noise signal of an infrared detector`s output at room temperature can be an order of magnitude smaller when cooled.

We used the cooling device we built as part of a study of semiconductors. Figure 1 shows the block diagram of the system; Figure 2 ( view Figure 2 ) shows the circuit schematic. The design uses the temperature feedback signal to optimize the system. The heart of the design is an ATmega8535 microcontroller. It produces a PWM (pulse-width modulation) signal based on a temperature measurement. A thermistor-to-digital converter produces a digital output on its three-wire SPI (serial peripheral interface), sending the data to the microcontroller. A TLC7524 DAC (digital-to-analog converter) generates a control voltage from the PWM signal. The voltage controls the cooling device through an op amp and MOSFET (Q1), which can produce up to 2 A of control current.

The Timer1 code reads the temperature data and computes an average value from 50 measurements. The Timer2 code compares the measured temperature to the temperature setting and adjusts the current to the cooling controller through the microcontroller`s PWM output signal. 🔗 External reference