Fogger controller

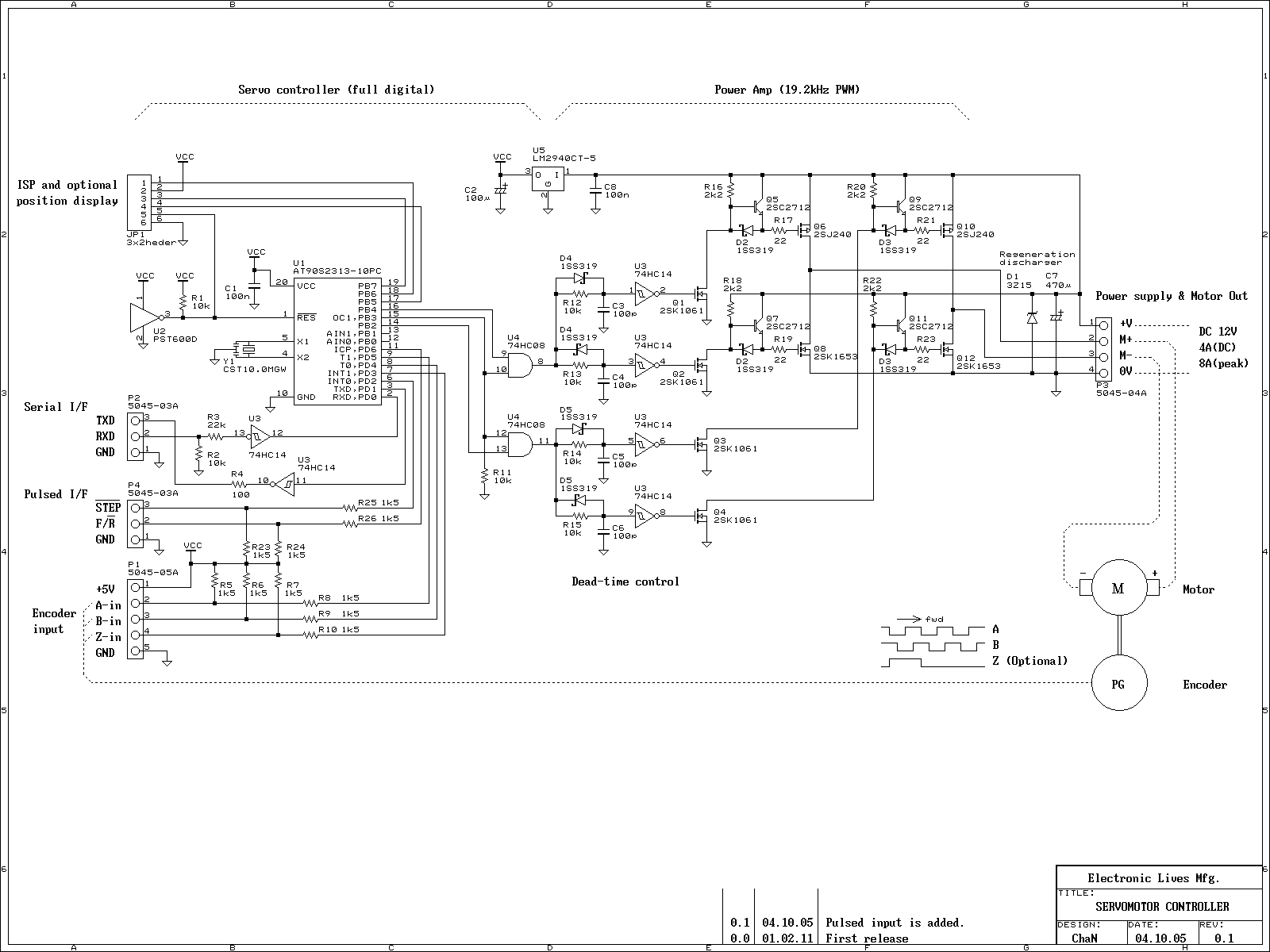

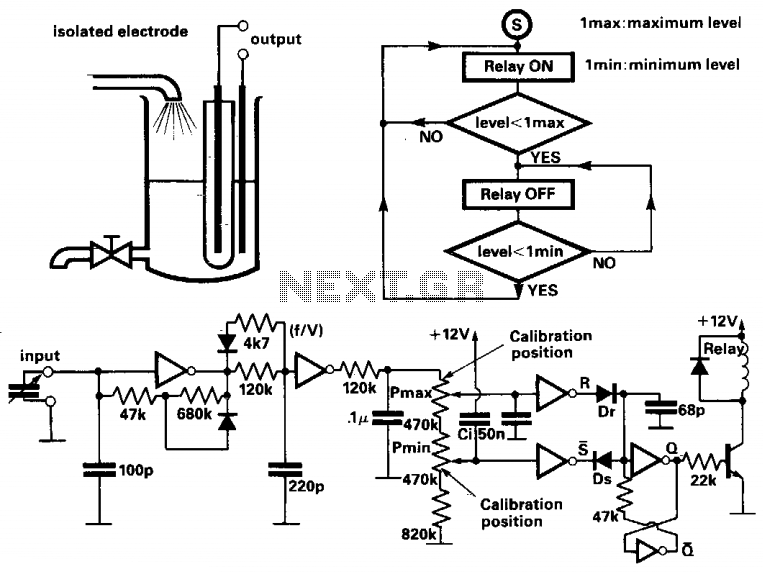

Foggers used to generate fog and smoke effects operate by heating a special fogger fluid. They consist of a heating element that is maintained at the correct temperature using a thermostat. When the operator wants to generate smoke, they press the controller button, which activates the pump to deliver fog fluid to the heating element. Upon entering the heating element, the fog fluid begins to evaporate and produce smoke. Inexpensive foggers typically feature a basic one-button controller, which is functional for initiating smoke effects but lacks the capability to maintain a constant fog level in a room. More advanced foggers are equipped with controllers that allow for adjustable, continuous fog generation at a slow rate. For those who own a budget smoke machine but desire the functionality found in higher-end models, the circuit presented on this webpage may prove beneficial. The SUPERSTAR FZ-920 SMOKE MACHINE utilizes a 3-pin IEC connector for the fogger remote controller, a type commonly used in computer equipment for grounded power connections. This application, however, employs the connector in a non-traditional manner. The following circuit diagram illustrates the remote controller circuit that accompanies the fogger. To enhance remote control capabilities, a relay was added in parallel with the existing button on the controller, along with a circuit to control that relay. It is important to note that the wiring of smoke machine controllers can differ significantly among manufacturers, and the controller for a specific smoke machine may have entirely different wiring and connector types. When power is supplied to the circuit by activating SW2, RELAY1 is energized for the duration required to charge capacitor C3 through resistors R1 and R3. Once charged, the relay de-energizes, and C3 discharges through resistors R2 and R4. The resistance of R2 determines the discharge time, which can extend up to one minute. After C3 discharges, the relay is activated again, and the charging process for C3 restarts, taking approximately 2 seconds. Following this, the relay de-energizes, and C3 begins to discharge once more. Each time the relay is energized, the smoke machine releases smoke for about 2 seconds, which is sufficient to emit a brief burst of fog fluid. The interval between smoke outputs can be adjusted, ranging from a nearly continuous output to a one-minute pause between bursts.

The circuit components are as follows:

- R1: 2.2 kΩ

- R2: 220 kΩ potentiometer

- R3: 4.7 kΩ

- R4: 820 Ω

- R5: 470 Ω

- D1: 1N4007

- D2: 1N4148

- D3: 1N4007

- D4: RED LED

- C2: 220 µF, 25V

- C3: 470 µF, 16V

- C4: 22 nF

- IC1: LM555 timer

- RELAY1: Relay with 12V coil and 250V, 4A contacts

- SW1: 250V, 4A switch

- SW2: General purpose low voltage switch, rated for at least 1A current

- GLIMM: GLIMM lamp with internal current limiting resistor (Rx) for 230V (panel light)

- CON: Male 3-pin IEC mains connector

This circuit design allows for effective control of fog generation, providing a versatile solution for users seeking to enhance their fog machine's functionality.Foggers used to generate fog and smoke effects operate by heating a special fogger fluid. They consist of a heting element which is kept in the right temperature using a thermostat. When the operator want to generate smoke, he/she presses the controller button which starts the pump which pumps fog fluid to the heating element. When smoke fluid ent ers the heating element, in starts to evaporate and produce smoke. Cheap foggers usually come with only a simple one button controller. This controller is useful for smoke starting smoke effects on user request, but is not very useful if you want to keep up a constant level of fog on the room. This is where more expensive foggers come to play, because they come usually with a controller which allows you to generate fog at some slow constant adjustable rate.

If you happen to own a cheap smoke machine and happen to want this kind of functionally only found on expensive models, the circuit shown on this web page might turn to be useful to you. SUPERSTAR FZ-920 SMOKE MACHINE uses 3 pin IEC connector for the fogger remote controller. This kind of connector is used on many computer equipments for connecting grounded power to the equipment.

In this application this connector is used in quite nin-traditional way. The following circuit diagram shows the circuit diagram of the remote controller which came with the fogger: But anyway that was ho the original product was designed. If I were the redigned of the smoke machine, I would have done the thing a little bit differently. If you want more information on the insides of the Superstar FZ-920 smoke machine, take a look at my crude drawing of the circuits inside FX-920 smoke machine.

To make this circuit remotely controllable, all I had to do was to add relay on parallel with the existing button on the controller and make a circuit which controls that relay. NOTE: The wiring of the controllers of the smoke machines can vary from manufacturer to manufacturer.

The controller of your smoke machine might be entirely differently wired and might even use different type of connector. When the power is connected to the circuit by turning on SW2, RELAY1 get energized for the time it get for it to load C3 through R1 and R3.

After that the relay get de-energized, C3 gets discharged through R2 and R4. The setting of R2 determines the discharge time which can be up to 1 minute. After C3 is discharged, the releay is activated. C3 charging starts again. The charging of C3 take around 2 seconds. After that relay is de-energized and C3 discharge starts again. Every time the relay is energised, the smoke machine is set to push out smoke. The time it puts out smoke is around 2 seconds, which was adequate to put out enough smoke fluid that the smoke machine puts out smoke for a brief amount. The iime between the smoke output is adjustable from practically constant smoke output to one minute pause between brief bursts of smoke.

R1 2. 2 kohm R2 220 kohm potentiometer R3 4. 7 kohm R4 820 ohms R5 470 ohms D1 1N4007 D3 1N4148 D3 1N4007 D4 RED LED C2 220 uF 25V C3 470 uF 16V C4 22 nF IC1 LM555 RELAY1 Relay with 12V coil and 250V 4A contacts SW1 250V 4A switch SW2 General purpose low voltag switch, at least 1A current rating GLIMM GLIMM lamp with internal current limiting resistor (Rx) for 230V (panel light) CON Male 3 pin IEC mains connector 🔗 External reference

The circuit components are as follows:

- R1: 2.2 kΩ

- R2: 220 kΩ potentiometer

- R3: 4.7 kΩ

- R4: 820 Ω

- R5: 470 Ω

- D1: 1N4007

- D2: 1N4148

- D3: 1N4007

- D4: RED LED

- C2: 220 µF, 25V

- C3: 470 µF, 16V

- C4: 22 nF

- IC1: LM555 timer

- RELAY1: Relay with 12V coil and 250V, 4A contacts

- SW1: 250V, 4A switch

- SW2: General purpose low voltage switch, rated for at least 1A current

- GLIMM: GLIMM lamp with internal current limiting resistor (Rx) for 230V (panel light)

- CON: Male 3-pin IEC mains connector

This circuit design allows for effective control of fog generation, providing a versatile solution for users seeking to enhance their fog machine's functionality.Foggers used to generate fog and smoke effects operate by heating a special fogger fluid. They consist of a heting element which is kept in the right temperature using a thermostat. When the operator want to generate smoke, he/she presses the controller button which starts the pump which pumps fog fluid to the heating element. When smoke fluid ent ers the heating element, in starts to evaporate and produce smoke. Cheap foggers usually come with only a simple one button controller. This controller is useful for smoke starting smoke effects on user request, but is not very useful if you want to keep up a constant level of fog on the room. This is where more expensive foggers come to play, because they come usually with a controller which allows you to generate fog at some slow constant adjustable rate.

If you happen to own a cheap smoke machine and happen to want this kind of functionally only found on expensive models, the circuit shown on this web page might turn to be useful to you. SUPERSTAR FZ-920 SMOKE MACHINE uses 3 pin IEC connector for the fogger remote controller. This kind of connector is used on many computer equipments for connecting grounded power to the equipment.

In this application this connector is used in quite nin-traditional way. The following circuit diagram shows the circuit diagram of the remote controller which came with the fogger: But anyway that was ho the original product was designed. If I were the redigned of the smoke machine, I would have done the thing a little bit differently. If you want more information on the insides of the Superstar FZ-920 smoke machine, take a look at my crude drawing of the circuits inside FX-920 smoke machine.

To make this circuit remotely controllable, all I had to do was to add relay on parallel with the existing button on the controller and make a circuit which controls that relay. NOTE: The wiring of the controllers of the smoke machines can vary from manufacturer to manufacturer.

The controller of your smoke machine might be entirely differently wired and might even use different type of connector. When the power is connected to the circuit by turning on SW2, RELAY1 get energized for the time it get for it to load C3 through R1 and R3.

After that the relay get de-energized, C3 gets discharged through R2 and R4. The setting of R2 determines the discharge time which can be up to 1 minute. After C3 is discharged, the releay is activated. C3 charging starts again. The charging of C3 take around 2 seconds. After that relay is de-energized and C3 discharge starts again. Every time the relay is energised, the smoke machine is set to push out smoke. The time it puts out smoke is around 2 seconds, which was adequate to put out enough smoke fluid that the smoke machine puts out smoke for a brief amount. The iime between the smoke output is adjustable from practically constant smoke output to one minute pause between brief bursts of smoke.

R1 2. 2 kohm R2 220 kohm potentiometer R3 4. 7 kohm R4 820 ohms R5 470 ohms D1 1N4007 D3 1N4148 D3 1N4007 D4 RED LED C2 220 uF 25V C3 470 uF 16V C4 22 nF IC1 LM555 RELAY1 Relay with 12V coil and 250V 4A contacts SW1 250V 4A switch SW2 General purpose low voltag switch, at least 1A current rating GLIMM GLIMM lamp with internal current limiting resistor (Rx) for 230V (panel light) CON Male 3 pin IEC mains connector 🔗 External reference