Current amplification for driving stepper motor

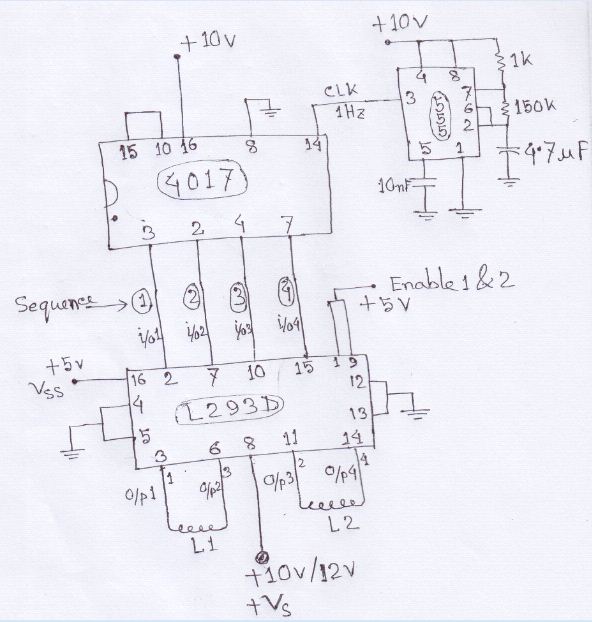

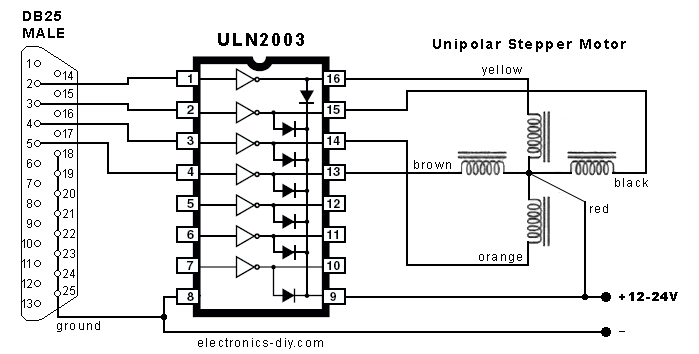

In the search for stepper drivers, the ULN2003 chip was discovered, which facilitates motor operation with minimal circuitry through the parallel port of a PC. However, the current output from the ULN2003 is limited to 500mA, resulting in low torque, making it easy to stop the motor manually. An alternative chip, the LMD18200, offers a current output of 3A, which could potentially drive the motor more effectively. The design employs the parallel port to control each phase of the stepper motor, which may result in slow performance, especially with three axes. It is suggested that using MOSFETs eliminates the need for a buffer chip and that a dedicated stepper driver chip could be a more practical solution for powering MOSFETs or Darlington transistors. Unless budget constraints are severe, investing in a better drive system is advisable. A discrete driver utilizing logic ICs for full stepping would significantly outperform the current setup. The initial design was chosen due to inexperience in electronics, with the aim of simply verifying motor functionality. In an attempt to increase current capacity, multiple ULN2003 chips were connected in parallel, although concerns remain about the feasibility of achieving 1.5A from a power adapter limited to 500mA.

The ULN2003 is a popular Darlington transistor array used for driving inductive loads such as stepper motors. Its limitation of 500mA output per channel can lead to insufficient torque for applications requiring higher performance. When considering alternatives like the LMD18200, which can handle up to 3A, it is crucial to evaluate the motor's specifications and the system's overall design to ensure compatibility and efficiency.

The use of a parallel port for controlling the stepper motor phases introduces a bottleneck in speed, particularly when managing multiple axes. This approach may not be suitable for applications demanding rapid and precise movements. Transitioning to a dedicated stepper driver IC, such as the A4988 or DRV8825, would provide improved control and current handling capabilities, allowing for smoother and more responsive motor operation.

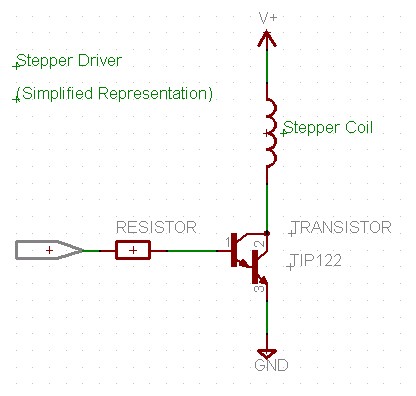

For a more robust design, incorporating MOSFETs as switches can enhance performance. In this case, a dedicated driver IC can effectively drive the MOSFETs, eliminating the need for additional buffer stages. Furthermore, implementing full-stepping control through logic ICs provides a reliable means of driving the stepper motor without the complexities associated with using multiple ULN2003 chips in parallel.

In terms of power supply considerations, connecting multiple ULN2003 chips in parallel does not increase the current output beyond the power adapter's limit. Therefore, if the power adapter is rated for only 500mA, achieving a total of 1.5A is not feasible without upgrading the power supply. Additional components, such as ceramic power resistors and large capacitors, may be required to stabilize the circuit and improve performance, particularly when using MOSFETs. Overall, a comprehensive redesign focusing on a dedicated driver solution, appropriate power supply, and optimized control logic will yield significantly better results for driving stepper motors in multi-axis applications.Looking for Stepper drivers i came across ULN2003 chip which allowed me to run the motor with minimum circuitry through the parallel port on my PC( I`m not an electronics person, hence searched for the simplest option out there). But the problem is the current output from ULN2003 is only 500mA. and hence the torque from the motor is very low ( i can stop it very easily using my hand) (if its of any help i came across this chip LMD18200 with current output of 3A. if its possible to drive the motor with any such chip that wud be wonderful) your design uses the parallel port to control each phase of the stepper. this is bound to be very slow! with 3 axis doing this, you are probably going to have trouble. if you want to use mosfets, you do not need the buffer chip. a better choice would be to look for a dedicated stepper driver chip to power the mosfets, or darlington transistors, as they may prove more practical.

unless your budget is very small, i would recommend looking at a better drive system. even a discrete driver using logic ICs to do `full stepping` will be significantly better than your current intentions. i used what you have on a 2D plotter device, and it sorta worked. You need o add in some more components to make just mosfets work relialably. i believe you will also need 1, 2, or more ceramic `power resistors`, a large capacitor. etc. your design uses the parallel port to control each phase of the stepper. this is bound to be very slow! with 3 axis doing this, you are probably going to have trouble. if you want to use mosfets, you do not need the buffer chip. a better choice would be to look for a dedicated stepper driver chip to power the mosfets, or darlington transistors, as they may prove more practical.

unless your budget is very small, i would recommend looking at a better drive system. even a discrete driver using logic ICs to do `full stepping` will be significantly better than your current intentions. i used what you have on a 2D plotter device, and it sorta worked. You need o add in some more components to make just mosfets work relialably. i believe you will also need 1, 2, or more ceramic `power resistors`, a large capacitor. etc. Abt th design. frankly i chose this one just because im a rookie in the field of electronics and at that time all i inetended to do was to check whether my motor was working or not.

So, in my desperation to get things moving i bought a few more ULN2003s since i had a faint recollection abt somebody telling me to connect these in parallel to get the required current. I know this isnt the best option but if this doesnt work out for me. but yes i had this question in my mind. if im using an adaptor with a current limit of 500mA to power the circuit is it possible to get 1. 5A current even after connecting 4 ULNs in parallel. 🔗 External reference

The ULN2003 is a popular Darlington transistor array used for driving inductive loads such as stepper motors. Its limitation of 500mA output per channel can lead to insufficient torque for applications requiring higher performance. When considering alternatives like the LMD18200, which can handle up to 3A, it is crucial to evaluate the motor's specifications and the system's overall design to ensure compatibility and efficiency.

The use of a parallel port for controlling the stepper motor phases introduces a bottleneck in speed, particularly when managing multiple axes. This approach may not be suitable for applications demanding rapid and precise movements. Transitioning to a dedicated stepper driver IC, such as the A4988 or DRV8825, would provide improved control and current handling capabilities, allowing for smoother and more responsive motor operation.

For a more robust design, incorporating MOSFETs as switches can enhance performance. In this case, a dedicated driver IC can effectively drive the MOSFETs, eliminating the need for additional buffer stages. Furthermore, implementing full-stepping control through logic ICs provides a reliable means of driving the stepper motor without the complexities associated with using multiple ULN2003 chips in parallel.

In terms of power supply considerations, connecting multiple ULN2003 chips in parallel does not increase the current output beyond the power adapter's limit. Therefore, if the power adapter is rated for only 500mA, achieving a total of 1.5A is not feasible without upgrading the power supply. Additional components, such as ceramic power resistors and large capacitors, may be required to stabilize the circuit and improve performance, particularly when using MOSFETs. Overall, a comprehensive redesign focusing on a dedicated driver solution, appropriate power supply, and optimized control logic will yield significantly better results for driving stepper motors in multi-axis applications.Looking for Stepper drivers i came across ULN2003 chip which allowed me to run the motor with minimum circuitry through the parallel port on my PC( I`m not an electronics person, hence searched for the simplest option out there). But the problem is the current output from ULN2003 is only 500mA. and hence the torque from the motor is very low ( i can stop it very easily using my hand) (if its of any help i came across this chip LMD18200 with current output of 3A. if its possible to drive the motor with any such chip that wud be wonderful) your design uses the parallel port to control each phase of the stepper. this is bound to be very slow! with 3 axis doing this, you are probably going to have trouble. if you want to use mosfets, you do not need the buffer chip. a better choice would be to look for a dedicated stepper driver chip to power the mosfets, or darlington transistors, as they may prove more practical.

unless your budget is very small, i would recommend looking at a better drive system. even a discrete driver using logic ICs to do `full stepping` will be significantly better than your current intentions. i used what you have on a 2D plotter device, and it sorta worked. You need o add in some more components to make just mosfets work relialably. i believe you will also need 1, 2, or more ceramic `power resistors`, a large capacitor. etc. your design uses the parallel port to control each phase of the stepper. this is bound to be very slow! with 3 axis doing this, you are probably going to have trouble. if you want to use mosfets, you do not need the buffer chip. a better choice would be to look for a dedicated stepper driver chip to power the mosfets, or darlington transistors, as they may prove more practical.

unless your budget is very small, i would recommend looking at a better drive system. even a discrete driver using logic ICs to do `full stepping` will be significantly better than your current intentions. i used what you have on a 2D plotter device, and it sorta worked. You need o add in some more components to make just mosfets work relialably. i believe you will also need 1, 2, or more ceramic `power resistors`, a large capacitor. etc. Abt th design. frankly i chose this one just because im a rookie in the field of electronics and at that time all i inetended to do was to check whether my motor was working or not.

So, in my desperation to get things moving i bought a few more ULN2003s since i had a faint recollection abt somebody telling me to connect these in parallel to get the required current. I know this isnt the best option but if this doesnt work out for me. but yes i had this question in my mind. if im using an adaptor with a current limit of 500mA to power the circuit is it possible to get 1. 5A current even after connecting 4 ULNs in parallel. 🔗 External reference