Small Stepper Motor

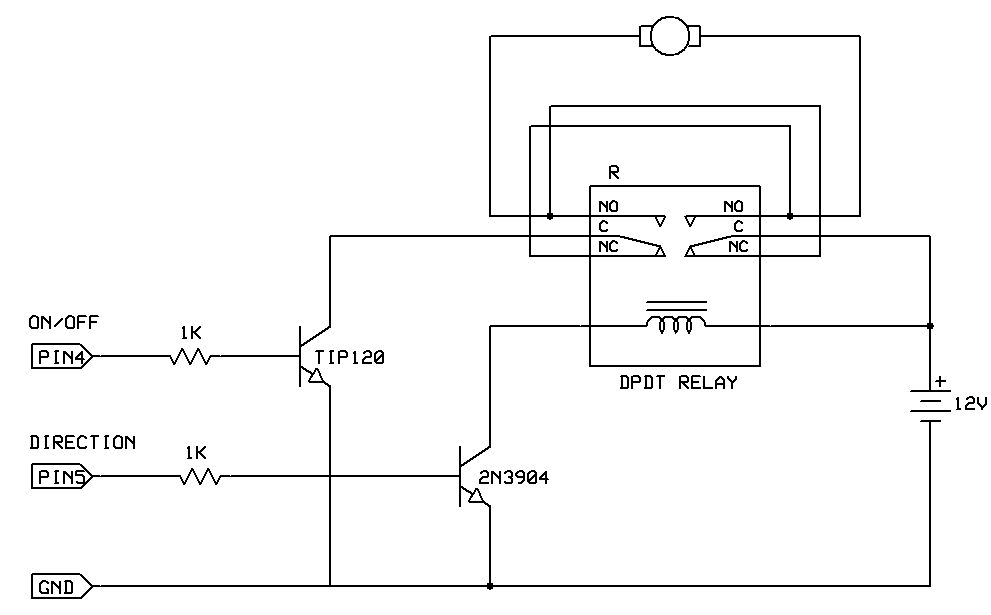

The objective is to operate a motor using an L293D Motor Drive Shield, which can handle 600mA per coil. The motor consumes 400mA per coil, suggesting compatibility. However, the datasheet does not clearly indicate the pinouts, only labeling them as coil A and coil B without specifying which wires correspond to each coil. The truth table is confusing, but it has been inferred that the yellow and orange wires represent one coil, while the brown and black wires represent another coil. There is unexpected connectivity/resistance between the orange and brown wires, which raises concerns when attempting to connect them according to the presumed pinout (Yellow/Orange as coil B and Brown/Black as coil A). The motor is programmed for one full rotation (48 pulses, calculated as 360/7.5) at a speed setting of 10, but it only achieves a quarter rotation, and the H-bridge chip overheats rapidly.

The L293D Motor Drive Shield is designed to control DC motors and stepper motors, providing the necessary current and voltage levels for effective operation. It can drive up to two DC motors simultaneously, with each output capable of supplying up to 600mA. In this case, the motor in question draws 400mA per coil, which is within the shield's specifications, allowing for safe operation under normal conditions.

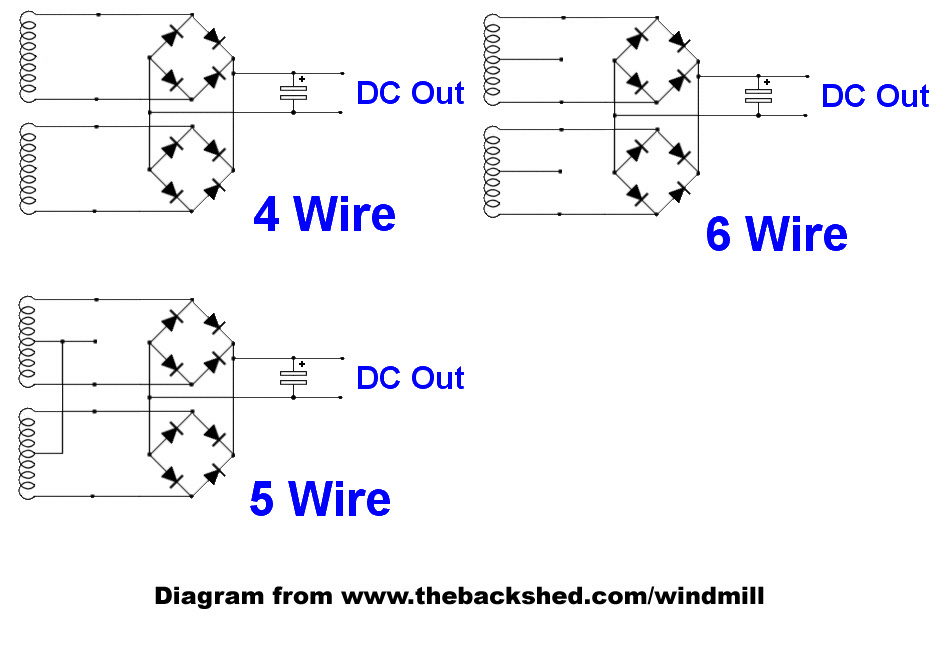

The confusion with the pinouts is a common issue when dealing with motors and motor drivers. Typically, stepper motors consist of two coils, each requiring a specific sequence of energization to achieve rotation. The L293D shield requires the correct identification of these coils to ensure proper functionality. The yellow and orange wires are likely connected to one coil, while the brown and black wires are connected to the other. It is crucial to ensure that these connections are made correctly to prevent unexpected behavior.

The observation of resistance between the orange and brown wires is concerning, as it suggests a possible short circuit or incorrect wiring. This condition can lead to excessive current draw, causing the H-bridge to overheat, which may explain the rapid temperature increase during operation. It is advisable to double-check all connections and ensure that the motor is wired in accordance with the intended configuration.

When programming the motor to perform a full rotation, the calculation for the number of pulses (48) is based on the step angle of 7.5 degrees per step. However, if the motor is only completing a quarter rotation, it may indicate an issue with the control signals or the wiring configuration. Adjustments to the pulse sequence, timing, or speed settings may be necessary to achieve the desired full rotation.

In summary, careful attention to the wiring configuration, verification of connections, and proper programming of the control signals are essential for the successful operation of the motor with the L293D Motor Drive Shield. Addressing the resistance issue and ensuring correct coil identification will help prevent overheating and achieve the intended motor performance.Trying to get this motor to work with a L293D Motor Drive Shield the shield is capable of handling 600mA per coil, this motor according to the data here takes 400mA (presumable per coil) so should be good there. However the data sheet here does not relay explain the pin outs only coil A and coil B but not which wires are which coil, the truth t

able is also a bit confusing, I am a programmer and i cant read it. i tried to do my own truth table and it seems to confirm my guess that yellow and orange is one coil, and brown and black is another coil, . however I am also showing connectivity/resistance between orange and brown, . that should not happen correct when i hook it up in what should be (as far as i can tell) the correct pin out, (Yellow/Orange as coil B) and (Brown/Black as coil A).

and setting full rotation to 48 (360/7. 5=48) then tell the motor to do one full rotation (48 pulses) (speed 10). All i get is a quarter rotation and a Hbridge chip that`s getting way to hot very quickly, 🔗 External reference

The L293D Motor Drive Shield is designed to control DC motors and stepper motors, providing the necessary current and voltage levels for effective operation. It can drive up to two DC motors simultaneously, with each output capable of supplying up to 600mA. In this case, the motor in question draws 400mA per coil, which is within the shield's specifications, allowing for safe operation under normal conditions.

The confusion with the pinouts is a common issue when dealing with motors and motor drivers. Typically, stepper motors consist of two coils, each requiring a specific sequence of energization to achieve rotation. The L293D shield requires the correct identification of these coils to ensure proper functionality. The yellow and orange wires are likely connected to one coil, while the brown and black wires are connected to the other. It is crucial to ensure that these connections are made correctly to prevent unexpected behavior.

The observation of resistance between the orange and brown wires is concerning, as it suggests a possible short circuit or incorrect wiring. This condition can lead to excessive current draw, causing the H-bridge to overheat, which may explain the rapid temperature increase during operation. It is advisable to double-check all connections and ensure that the motor is wired in accordance with the intended configuration.

When programming the motor to perform a full rotation, the calculation for the number of pulses (48) is based on the step angle of 7.5 degrees per step. However, if the motor is only completing a quarter rotation, it may indicate an issue with the control signals or the wiring configuration. Adjustments to the pulse sequence, timing, or speed settings may be necessary to achieve the desired full rotation.

In summary, careful attention to the wiring configuration, verification of connections, and proper programming of the control signals are essential for the successful operation of the motor with the L293D Motor Drive Shield. Addressing the resistance issue and ensuring correct coil identification will help prevent overheating and achieve the intended motor performance.Trying to get this motor to work with a L293D Motor Drive Shield the shield is capable of handling 600mA per coil, this motor according to the data here takes 400mA (presumable per coil) so should be good there. However the data sheet here does not relay explain the pin outs only coil A and coil B but not which wires are which coil, the truth t

able is also a bit confusing, I am a programmer and i cant read it. i tried to do my own truth table and it seems to confirm my guess that yellow and orange is one coil, and brown and black is another coil, . however I am also showing connectivity/resistance between orange and brown, . that should not happen correct when i hook it up in what should be (as far as i can tell) the correct pin out, (Yellow/Orange as coil B) and (Brown/Black as coil A).

and setting full rotation to 48 (360/7. 5=48) then tell the motor to do one full rotation (48 pulses) (speed 10). All i get is a quarter rotation and a Hbridge chip that`s getting way to hot very quickly, 🔗 External reference