DC Servomotor Controller

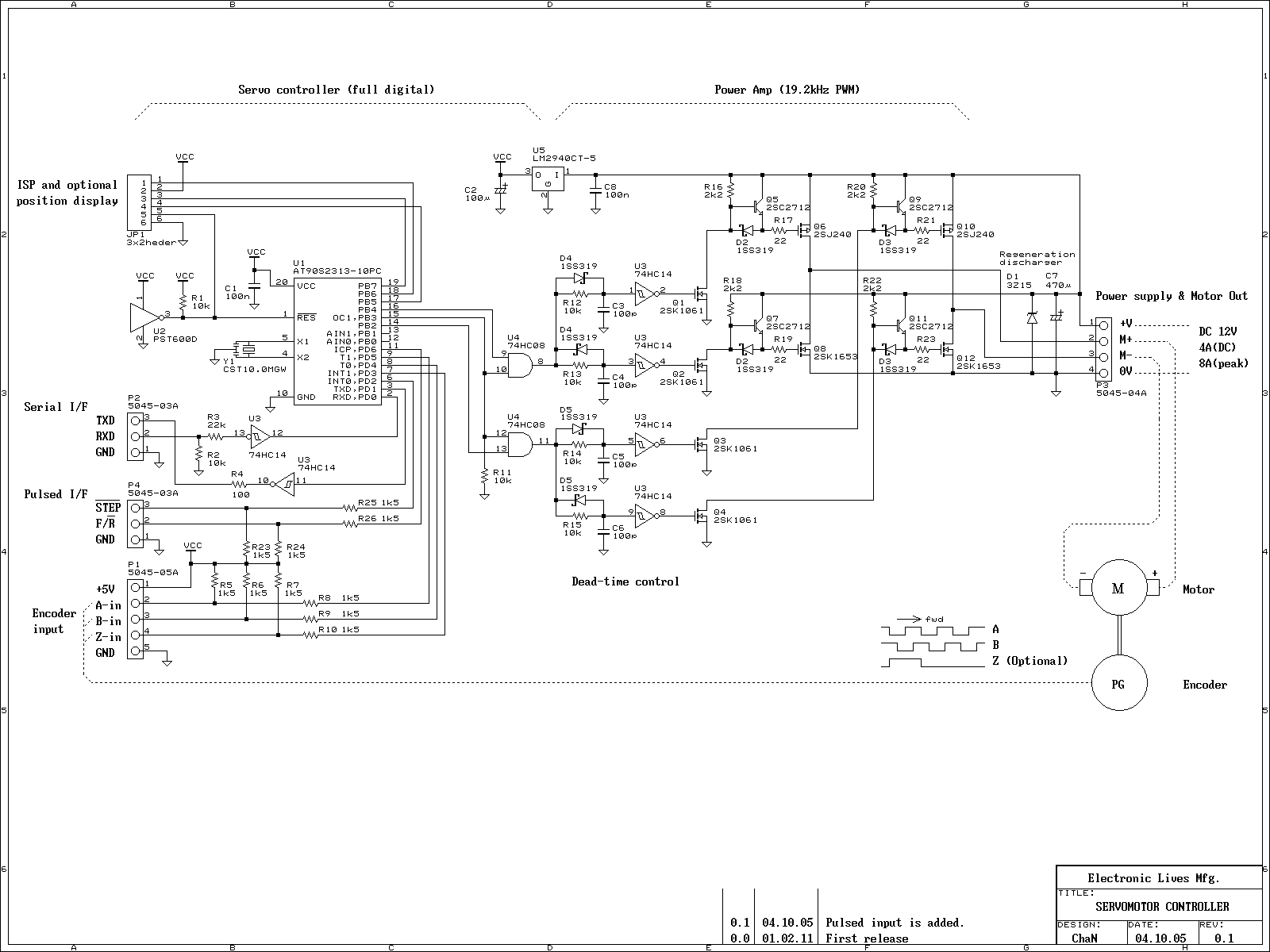

This is an experiment on the closed loop DC servomotor control system (SMC). It will be able to be used for practical use with/without some modifications. The closed loop servo mechanism requires real-time servo operations, such as position control, velocity control, and torque control. It will be suitable for implementation to any embedded 32-bit RISC processors as middleware. In this project, these operations are processed with only a cheap 8-bit microcontroller.

Recently, most servo systems are using brushless motors called "AC servo motor" to reduce maintenance cost. The AC servo motor with PM rotor is a kind of

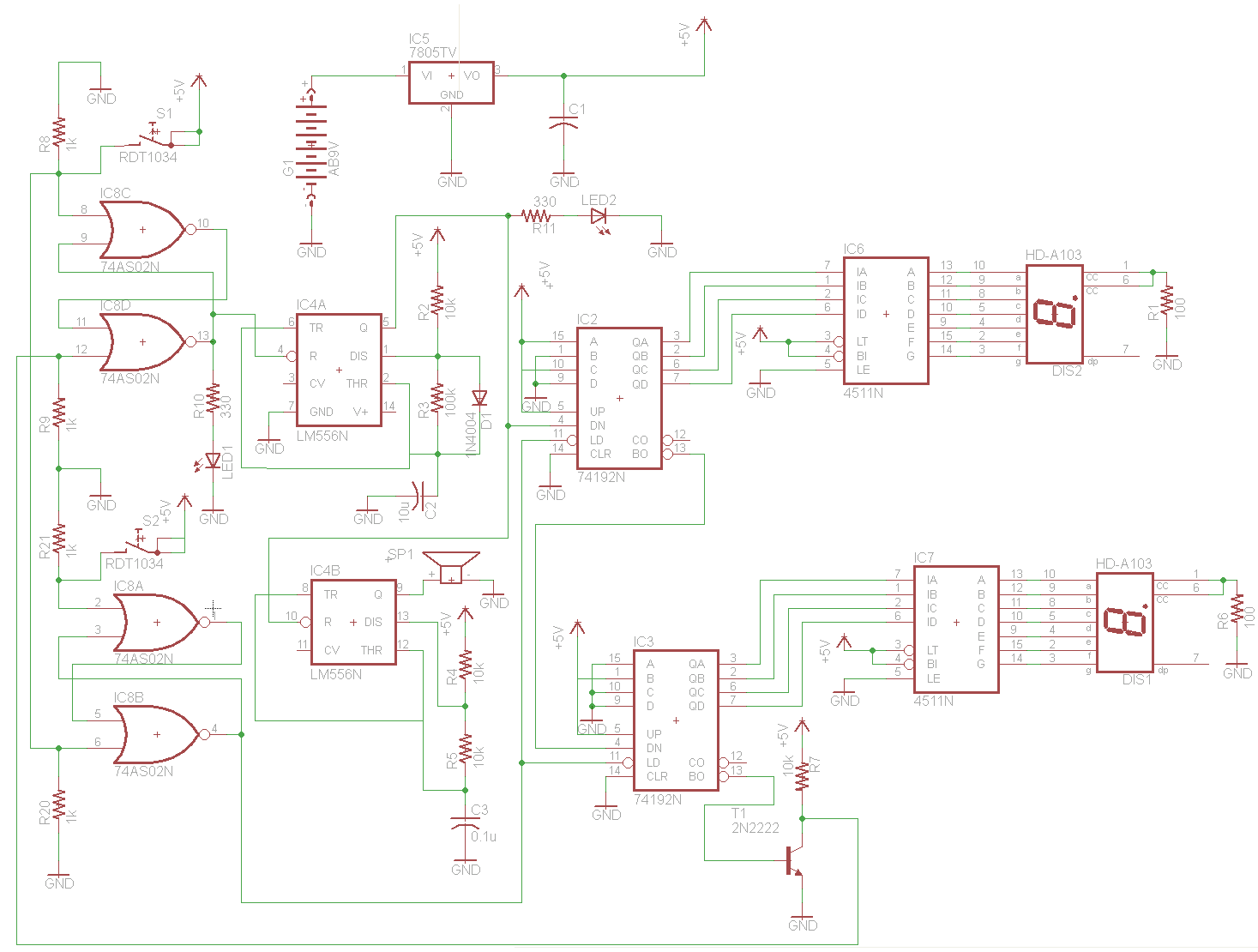

The closed-loop DC servomotor control system (SMC) is designed to enhance precision in various applications by continuously monitoring and adjusting the motor's performance based on feedback from sensors. This system typically employs a combination of position, velocity, and torque control strategies to achieve the desired operational parameters.

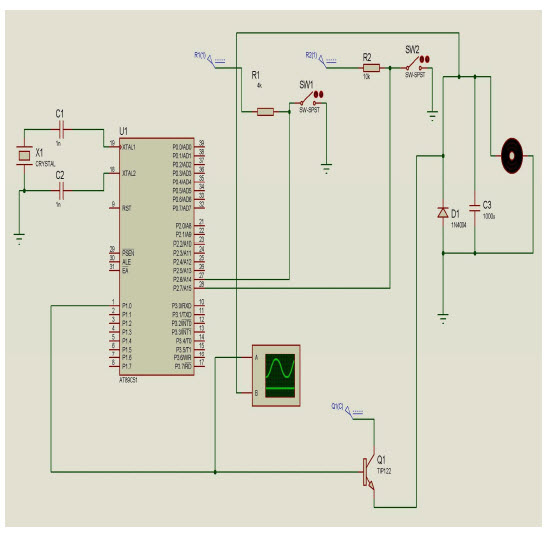

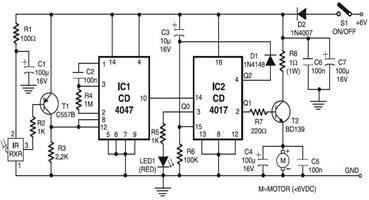

The core of the closed-loop system consists of a DC servomotor, which is driven by a power amplifier that receives commands from a microcontroller. The microcontroller processes input from sensors, such as encoders or potentiometers, which provide real-time data on the motor's position and speed. The control algorithms implemented in the microcontroller can be designed using various techniques, including PID (Proportional-Integral-Derivative) control, which is effective in minimizing the error between the desired and actual motor performance.

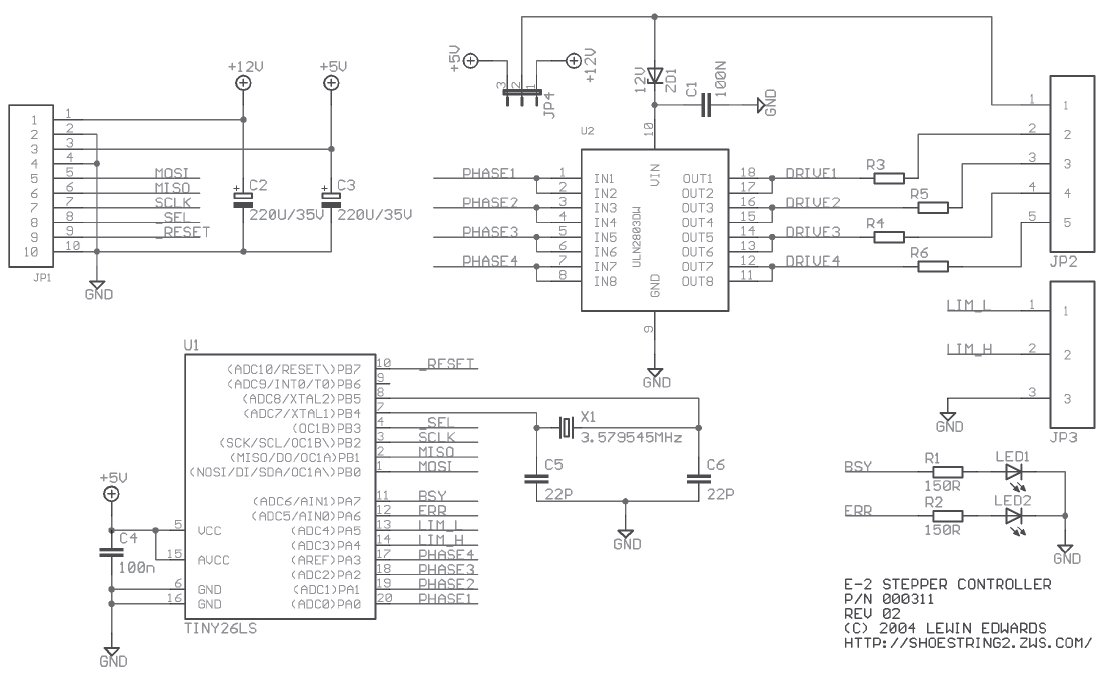

In this specific project, a cost-effective 8-bit microcontroller is utilized to manage the control logic, making it accessible for practical applications without the need for high-end processing capabilities. The microcontroller interfaces with the motor driver circuit, which may include H-bridge configurations to allow for bidirectional control of the motor.

The system's adaptability to 32-bit RISC processors as middleware indicates that it can be scaled or modified for more complex applications, such as robotics or automation systems, where enhanced processing power and additional functionalities may be required.

Furthermore, the trend towards utilizing brushless motors, particularly AC servo motors, is noteworthy. These motors offer advantages such as higher efficiency, reduced maintenance due to the absence of brushes, and better performance characteristics. The integration of Permanent Magnet (PM) rotors in AC servo motors contributes to their effectiveness in various applications, providing smooth operation and improved torque-to-weight ratios.

Overall, the closed-loop DC servomotor control system serves as a foundational technology for a wide range of automated systems, providing essential features that can be tailored to meet specific operational requirements.This is an experiment on the closed loop DC servomotor control system (SMC). It will able to be used for practical use with/without some modifications. The closed loop servo mechanism requires real-time servo operations, such as position control, velocity control and torque control. It will be suitable for implementation to any embedded 32 bit RISC processors as a middleware. In this project, these operations are processed with only a cheap 8 bit microcontroller. Recently, most servo systems are using brushless motors called "AC servo motor" to reduce maintanance cost. The AC servo motor with PM rotor is a kind of 🔗 External reference

Recently, most servo systems are using brushless motors called "AC servo motor" to reduce maintenance cost. The AC servo motor with PM rotor is a kind of

The closed-loop DC servomotor control system (SMC) is designed to enhance precision in various applications by continuously monitoring and adjusting the motor's performance based on feedback from sensors. This system typically employs a combination of position, velocity, and torque control strategies to achieve the desired operational parameters.

The core of the closed-loop system consists of a DC servomotor, which is driven by a power amplifier that receives commands from a microcontroller. The microcontroller processes input from sensors, such as encoders or potentiometers, which provide real-time data on the motor's position and speed. The control algorithms implemented in the microcontroller can be designed using various techniques, including PID (Proportional-Integral-Derivative) control, which is effective in minimizing the error between the desired and actual motor performance.

In this specific project, a cost-effective 8-bit microcontroller is utilized to manage the control logic, making it accessible for practical applications without the need for high-end processing capabilities. The microcontroller interfaces with the motor driver circuit, which may include H-bridge configurations to allow for bidirectional control of the motor.

The system's adaptability to 32-bit RISC processors as middleware indicates that it can be scaled or modified for more complex applications, such as robotics or automation systems, where enhanced processing power and additional functionalities may be required.

Furthermore, the trend towards utilizing brushless motors, particularly AC servo motors, is noteworthy. These motors offer advantages such as higher efficiency, reduced maintenance due to the absence of brushes, and better performance characteristics. The integration of Permanent Magnet (PM) rotors in AC servo motors contributes to their effectiveness in various applications, providing smooth operation and improved torque-to-weight ratios.

Overall, the closed-loop DC servomotor control system serves as a foundational technology for a wide range of automated systems, providing essential features that can be tailored to meet specific operational requirements.This is an experiment on the closed loop DC servomotor control system (SMC). It will able to be used for practical use with/without some modifications. The closed loop servo mechanism requires real-time servo operations, such as position control, velocity control and torque control. It will be suitable for implementation to any embedded 32 bit RISC processors as a middleware. In this project, these operations are processed with only a cheap 8 bit microcontroller. Recently, most servo systems are using brushless motors called "AC servo motor" to reduce maintanance cost. The AC servo motor with PM rotor is a kind of 🔗 External reference