Design of the electrical machinery umbilical low-powered stabilized voltage supply

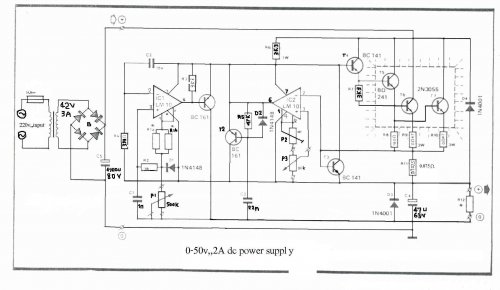

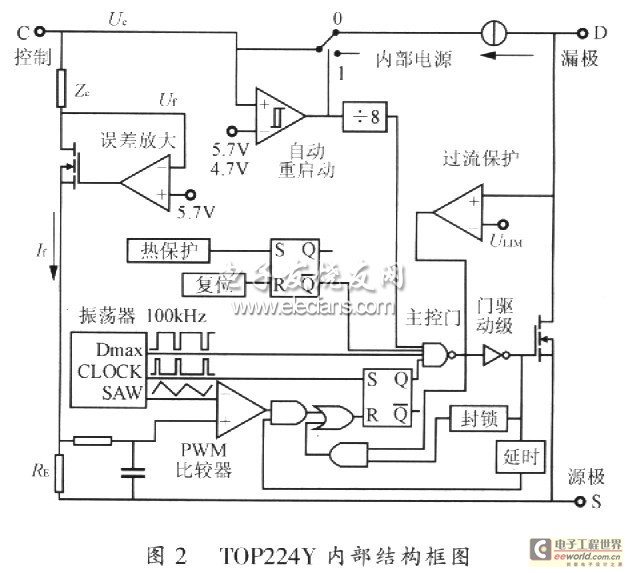

The Brushless DC motor with permanent magnetism is an advanced electrical machine characterized by innovative principles and technology. It consists of three main components: the Brushless DC motor body (BLDCM), a trochanter position transducer (RPS), and a control unit (CU), forming an integrated electromechanical system. This machinery has addressed many drawbacks associated with traditional brush motors, leading to rapid development and widespread application across various fields. The umbilical power supply primarily provides electrical energy to the control device's various chips, utilizing multi-channel voltage output through high-frequency DC/DC converters and isolated switch-mode power supplies. The main input for the umbilical is minimal but must be simple, reliable, and stable. Traditional switching power supplies, which rely on discrete components, often suffer from circuit complexity, inefficiency, and reliability issues. The TOPSwitch series integrated chips from PI Power Integration effectively solve these problems by operating at a frequency of 100 kHz, resulting in a simplified peripheral circuit, reduced electromagnetic interference, lower costs, and decreased volume and weight of the control device, thereby enhancing system reliability. The design incorporates the TOP224Y chip to create a single-ended, anti-exciting type switching power supply for the control device. This type of converter, also known as an energy-storing inductive converter, simultaneously stores energy in the voltage transformer while providing electrical isolation. The schematic circuit diagram illustrates that when the high-voltage gas switching tube (S1) is activated, the direct input voltage (V1) is applied across the primary winding (Lp) of the transformer, storing energy in the inductance. When S1 is turned off, the polarity of the primary voltage reverses, causing the secondary voltage to also reverse, which activates the diode (D) and allows the stored energy to be transferred to the output capacitance (C). This process repeats as the switching tube is cycled. The TOP224Y chip is a typical three-terminal device, featuring control, source, and drain pins, with an internal MOSFET rated for 700V. It supports a wide input voltage range of 85-265V and achieves an AC/DC conversion efficiency of up to 90%. The chip integrates the power switching tube and its control circuitry on a single chip, with built-in features for automatic resetting, overheat protection, and overcurrent protection, contributing to a high level of integration.

The Brushless DC motor (BLDCM) represents a significant advancement in electrical machinery, leveraging permanent magnetism for improved performance and efficiency. The integration of the RPS and CU into a cohesive system allows for precise control and feedback, enhancing the operational capabilities of the motor. The umbilical power supply plays a critical role in powering the control unit, ensuring that it operates reliably in various conditions. The use of high-frequency DC/DC converters facilitates efficient power management, allowing for the conversion of external input voltages into the necessary levels for the control device.

The design of the power supply utilizing the TOP224Y chip exemplifies modern approaches to power management, addressing the limitations of traditional switching power supplies. By minimizing component count and complexity, the system not only reduces manufacturing costs but also enhances reliability and performance. The anti-exciting type converter effectively manages energy transfer, ensuring that the system operates smoothly during switching cycles.

The TOP224Y chip's features, including its high voltage tolerance and efficiency, make it an ideal choice for applications requiring robust power management solutions. Its integration of essential protective functions further enhances the system's reliability, making it suitable for various applications in demanding environments. Overall, the combination of the Brushless DC motor, advanced control systems, and efficient power supply design represents a significant step forward in the field of electrical engineering, paving the way for future innovations in motor technology and control systems.The Brusless DC motor of permanent magnetism is a new electrical machinery with new principle, innovative technology, new method at present, it is by the Brusless DC motor body of permanent magnetism BLDCM, trochanter position transducer RPS And control device CU Three parts of constituent electromechanics` integrated systems. This electrical mac hinery has overcome a great deal of drawbacks of the brush motor, so, develop quickly in recent years, have already applied to a lot of fields. The umbilical power mainly provides the electric energy for various chips of the control device, adopt, give control device chip to power after the multi-channel voltage output through high-frequency the intersection of DC/DC and isolated the intersection of switch and source transformations the intersection of system and external input voltage generally.

Umbilical main input is minor, but require simple and reliable, good stability. The traditional switching power supply adopts the discrete components and parts, shortcoming of it is bad to store in circuit complicatedness, inefficiency, reliabilitying etc. U. S. A. PI Power Integration The specialized integrated chip of TOPSwitch series switching power supply that the company introduces can well solve these problems, make frequency as 100kHz on it, the peripheral circuit is simple, electromagnetic disturbance is small, the cost is cheap, can reduce volume and weight of the control device effectively, and strengthen the reliability of system work.

Originally design choosing TOP224Y chip among themming forms the anti exciting type switching power supply of single-end as the control device power. The anti exciting type converter of single-end is also called the energy-storing type converter of the inductance, its voltage transformer has stored energy concurrently, isolates and does Sichuan doubly.

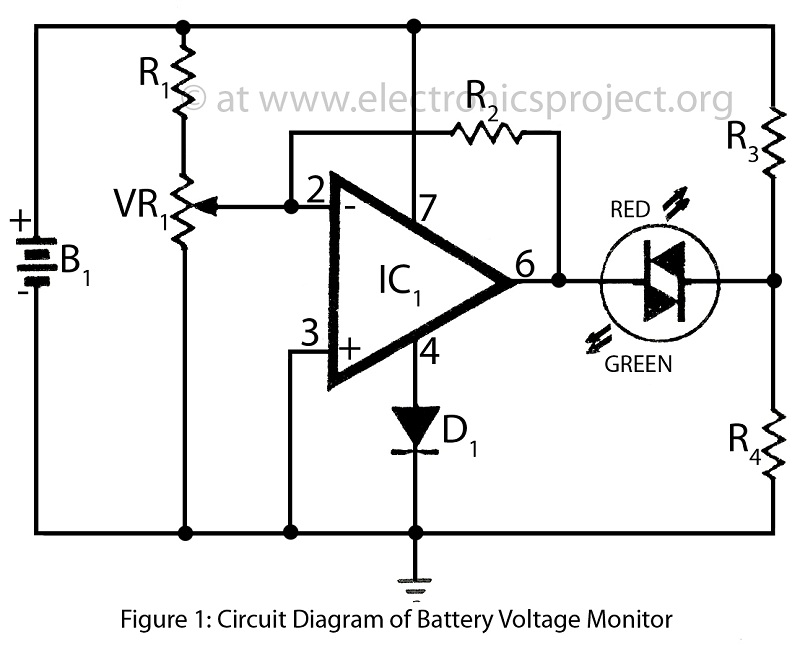

Fig. l is their schematic circuit diagrams. The so-called single-end, mean the magnetic core of the voltage transformer only works on its collinear side of magnetic Hysteresis. When the high-pressure gas switching tube S1 is turned on, the direct-flow input voltage V1 is added at first rear axle winding Lp both ends, it is at voltage transformer in primary side inductance coil stored energy, because secondary coil phase place for at if you can`t shoulder, down, make the diode D reversal of biasing end, the secondary loop does not have electric current that flow through, power energy is turned into magnetic energy and stored in the inductance at this moment.

When S1 ends, the polarity reversal of the primary side voltage, make the polarity reversal of the secondary voltage come over, thus the diode D is turned on, the energy stored in the voltage transformer is transmitted to supporting, charge output capacitance C at the same time, magnetic energy is turned into the electric energy and released out at this moment. When the gas switching tube is turned on again, the load current is offered by the electric capacity C, the stored energy again of primary side of the voltage transformer at the same time, so repeated.

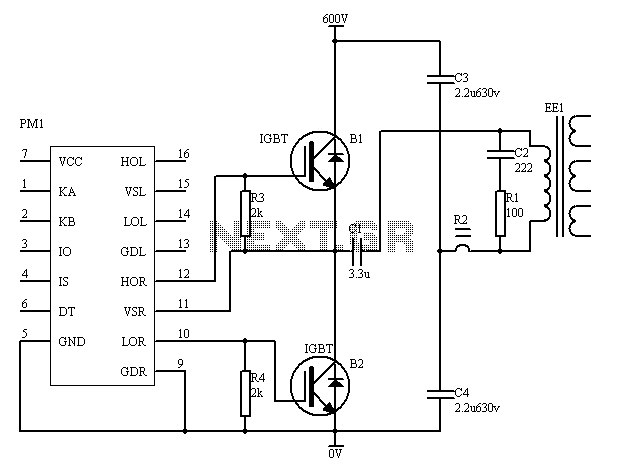

Can be found out from the above-mentioned circuit analysis, when S1 turns on, there is not electric current in the secondary loop; When S1 ends, there is electric current in the secondary loop, this is calling it anti exciting ly Meaning. TOP224Y is one kind of TOPSwitch series integrated chip, it is a typical three terminal device, three base pins are control pole C source S and drain D respectively, its internal MOSFET withstand voltage value is up to 700V.

It have the intersection of wide-voltage and input span exchange input voltage to be reachable 85- 265V, AC/DC conversion efficiency is reachable 90%. It integrates power gas switching tube and its controlling circuit in on-chip one, and have function of resetting automatically, overheat protective and overcurrent protection, etc.

Because it have very high integrated level an 🔗 External reference

The Brushless DC motor (BLDCM) represents a significant advancement in electrical machinery, leveraging permanent magnetism for improved performance and efficiency. The integration of the RPS and CU into a cohesive system allows for precise control and feedback, enhancing the operational capabilities of the motor. The umbilical power supply plays a critical role in powering the control unit, ensuring that it operates reliably in various conditions. The use of high-frequency DC/DC converters facilitates efficient power management, allowing for the conversion of external input voltages into the necessary levels for the control device.

The design of the power supply utilizing the TOP224Y chip exemplifies modern approaches to power management, addressing the limitations of traditional switching power supplies. By minimizing component count and complexity, the system not only reduces manufacturing costs but also enhances reliability and performance. The anti-exciting type converter effectively manages energy transfer, ensuring that the system operates smoothly during switching cycles.

The TOP224Y chip's features, including its high voltage tolerance and efficiency, make it an ideal choice for applications requiring robust power management solutions. Its integration of essential protective functions further enhances the system's reliability, making it suitable for various applications in demanding environments. Overall, the combination of the Brushless DC motor, advanced control systems, and efficient power supply design represents a significant step forward in the field of electrical engineering, paving the way for future innovations in motor technology and control systems.The Brusless DC motor of permanent magnetism is a new electrical machinery with new principle, innovative technology, new method at present, it is by the Brusless DC motor body of permanent magnetism BLDCM, trochanter position transducer RPS And control device CU Three parts of constituent electromechanics` integrated systems. This electrical mac hinery has overcome a great deal of drawbacks of the brush motor, so, develop quickly in recent years, have already applied to a lot of fields. The umbilical power mainly provides the electric energy for various chips of the control device, adopt, give control device chip to power after the multi-channel voltage output through high-frequency the intersection of DC/DC and isolated the intersection of switch and source transformations the intersection of system and external input voltage generally.

Umbilical main input is minor, but require simple and reliable, good stability. The traditional switching power supply adopts the discrete components and parts, shortcoming of it is bad to store in circuit complicatedness, inefficiency, reliabilitying etc. U. S. A. PI Power Integration The specialized integrated chip of TOPSwitch series switching power supply that the company introduces can well solve these problems, make frequency as 100kHz on it, the peripheral circuit is simple, electromagnetic disturbance is small, the cost is cheap, can reduce volume and weight of the control device effectively, and strengthen the reliability of system work.

Originally design choosing TOP224Y chip among themming forms the anti exciting type switching power supply of single-end as the control device power. The anti exciting type converter of single-end is also called the energy-storing type converter of the inductance, its voltage transformer has stored energy concurrently, isolates and does Sichuan doubly.

Fig. l is their schematic circuit diagrams. The so-called single-end, mean the magnetic core of the voltage transformer only works on its collinear side of magnetic Hysteresis. When the high-pressure gas switching tube S1 is turned on, the direct-flow input voltage V1 is added at first rear axle winding Lp both ends, it is at voltage transformer in primary side inductance coil stored energy, because secondary coil phase place for at if you can`t shoulder, down, make the diode D reversal of biasing end, the secondary loop does not have electric current that flow through, power energy is turned into magnetic energy and stored in the inductance at this moment.

When S1 ends, the polarity reversal of the primary side voltage, make the polarity reversal of the secondary voltage come over, thus the diode D is turned on, the energy stored in the voltage transformer is transmitted to supporting, charge output capacitance C at the same time, magnetic energy is turned into the electric energy and released out at this moment. When the gas switching tube is turned on again, the load current is offered by the electric capacity C, the stored energy again of primary side of the voltage transformer at the same time, so repeated.

Can be found out from the above-mentioned circuit analysis, when S1 turns on, there is not electric current in the secondary loop; When S1 ends, there is electric current in the secondary loop, this is calling it anti exciting ly Meaning. TOP224Y is one kind of TOPSwitch series integrated chip, it is a typical three terminal device, three base pins are control pole C source S and drain D respectively, its internal MOSFET withstand voltage value is up to 700V.

It have the intersection of wide-voltage and input span exchange input voltage to be reachable 85- 265V, AC/DC conversion efficiency is reachable 90%. It integrates power gas switching tube and its controlling circuit in on-chip one, and have function of resetting automatically, overheat protective and overcurrent protection, etc.

Because it have very high integrated level an 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713