Fluorescent light circuits at low temperature and pressure

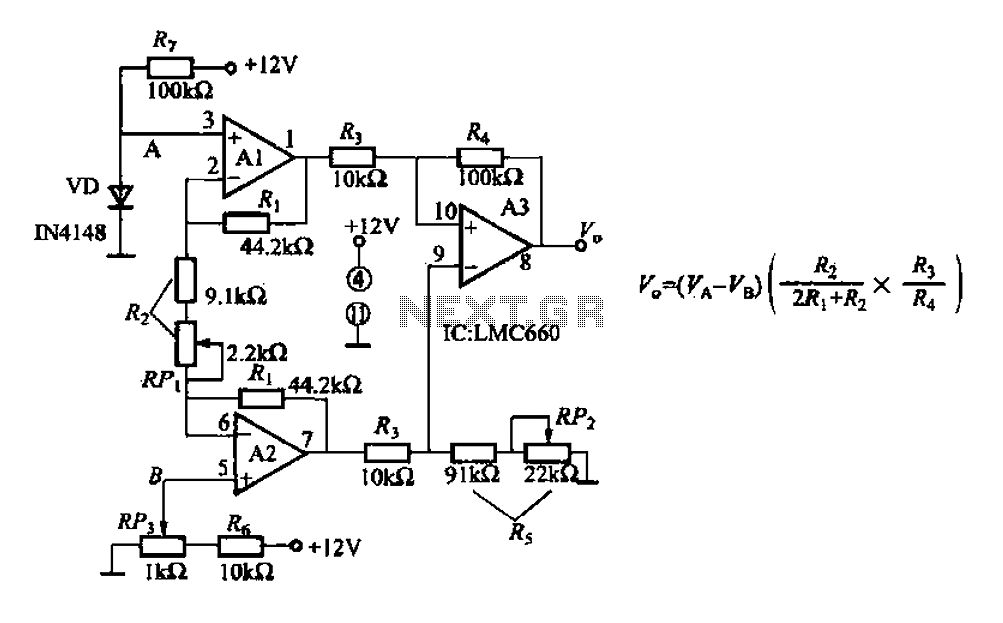

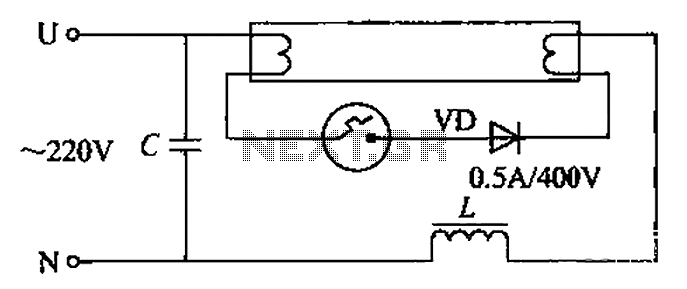

By incorporating a second pull tube into the circuit during the starter ionization phase, the positive half-cycle diode conduction results in an approximate DC current flow. This current is rectified, and due to the small ballast impedance, the instantaneous current flowing through the filament increases significantly, enhancing electron transmission capability. Additionally, the high current in the ballast leads to substantial stored magnetic energy. When the circuit is disconnected at the starting instant, the self-inductance generates a higher electric potential, facilitating easier lamp ignition. If the diode lamp still struggles to start, reversing the connections may be necessary. This method can expedite lamp ignition and prolong lamp life. For optimal performance, any tube selected should withstand a reverse voltage of 400V and a rectified current of 500mA. This circuit can effectively ignite 8W and 20W fluorescent lamps quickly at -10V to 180V.

The circuit described utilizes a dual pull tube configuration to enhance the ionization process during lamp startup. The addition of a second pull tube improves the overall efficiency of the circuit by allowing for more effective current flow during the positive half-cycle of the AC signal. The diode conducts during this phase, converting the AC input into a rectified DC output, which is crucial for the operation of fluorescent lamps.

The ballast in this circuit is designed with low impedance, which minimizes resistance and allows for a significant instantaneous current to pass through the filament. This increased current is vital for the initial heating of the filament, which in turn facilitates the emission of electrons necessary for lamp ignition. The high current flowing through the ballast also stores magnetic energy, which is released when the circuit is interrupted, creating a high electric potential due to the self-inductance of the ballast. This phenomenon is critical in ensuring that the lamp can ignite with minimal delay.

In cases where the lamp fails to start, reversing the connections may resolve the issue, indicating that the circuit's design is sensitive to the orientation of the components. The outlined method not only aids in faster lamp ignition but also contributes to extending the operational life of the lamp by optimizing the startup conditions.

For practical implementation, it is recommended that any selected tube should have a reverse voltage rating of 400V and be capable of handling a rectified current of 500mA. This specification ensures that the circuit can operate efficiently across a range of voltages, specifically from -10V to 180V, making it suitable for quickly igniting both 8W and 20W fluorescent lamps. The overall design emphasizes reliability and efficiency, making it a valuable solution for fluorescent lamp applications. By adding a second pull tube in the circuit, when the starter ionization. In the positive half cycle diode conduction, from the whole flow effect, the current in the circuit is approximately DC. This current is rectified, the ballast impedance is small, so that the instantaneous current flowing through the filament plus large, enhancing the ability to transmit electrons. On the other hand, the current flowing in the ballast is large, the stored magnetic energy is large, the start instant is disconnected, the self-inductance of the electric potential is higher.

Therefore, the lamp is easy to start to ignite. If trespassing on the diode lamp is still not easy to start, you should start the feet were reversed. The above-described method can accelerate the lamp start, Ai extend lamp life. Second board any type of tube should be selected reverse voltage 400fr, rectified current of 500mA diode tube.

Such a circuit can be at -10, 180V voltage, 8w and 20W fluorescent lamp lit fast start.

The circuit described utilizes a dual pull tube configuration to enhance the ionization process during lamp startup. The addition of a second pull tube improves the overall efficiency of the circuit by allowing for more effective current flow during the positive half-cycle of the AC signal. The diode conducts during this phase, converting the AC input into a rectified DC output, which is crucial for the operation of fluorescent lamps.

The ballast in this circuit is designed with low impedance, which minimizes resistance and allows for a significant instantaneous current to pass through the filament. This increased current is vital for the initial heating of the filament, which in turn facilitates the emission of electrons necessary for lamp ignition. The high current flowing through the ballast also stores magnetic energy, which is released when the circuit is interrupted, creating a high electric potential due to the self-inductance of the ballast. This phenomenon is critical in ensuring that the lamp can ignite with minimal delay.

In cases where the lamp fails to start, reversing the connections may resolve the issue, indicating that the circuit's design is sensitive to the orientation of the components. The outlined method not only aids in faster lamp ignition but also contributes to extending the operational life of the lamp by optimizing the startup conditions.

For practical implementation, it is recommended that any selected tube should have a reverse voltage rating of 400V and be capable of handling a rectified current of 500mA. This specification ensures that the circuit can operate efficiently across a range of voltages, specifically from -10V to 180V, making it suitable for quickly igniting both 8W and 20W fluorescent lamps. The overall design emphasizes reliability and efficiency, making it a valuable solution for fluorescent lamp applications. By adding a second pull tube in the circuit, when the starter ionization. In the positive half cycle diode conduction, from the whole flow effect, the current in the circuit is approximately DC. This current is rectified, the ballast impedance is small, so that the instantaneous current flowing through the filament plus large, enhancing the ability to transmit electrons. On the other hand, the current flowing in the ballast is large, the stored magnetic energy is large, the start instant is disconnected, the self-inductance of the electric potential is higher.

Therefore, the lamp is easy to start to ignite. If trespassing on the diode lamp is still not easy to start, you should start the feet were reversed. The above-described method can accelerate the lamp start, Ai extend lamp life. Second board any type of tube should be selected reverse voltage 400fr, rectified current of 500mA diode tube.

Such a circuit can be at -10, 180V voltage, 8w and 20W fluorescent lamp lit fast start.