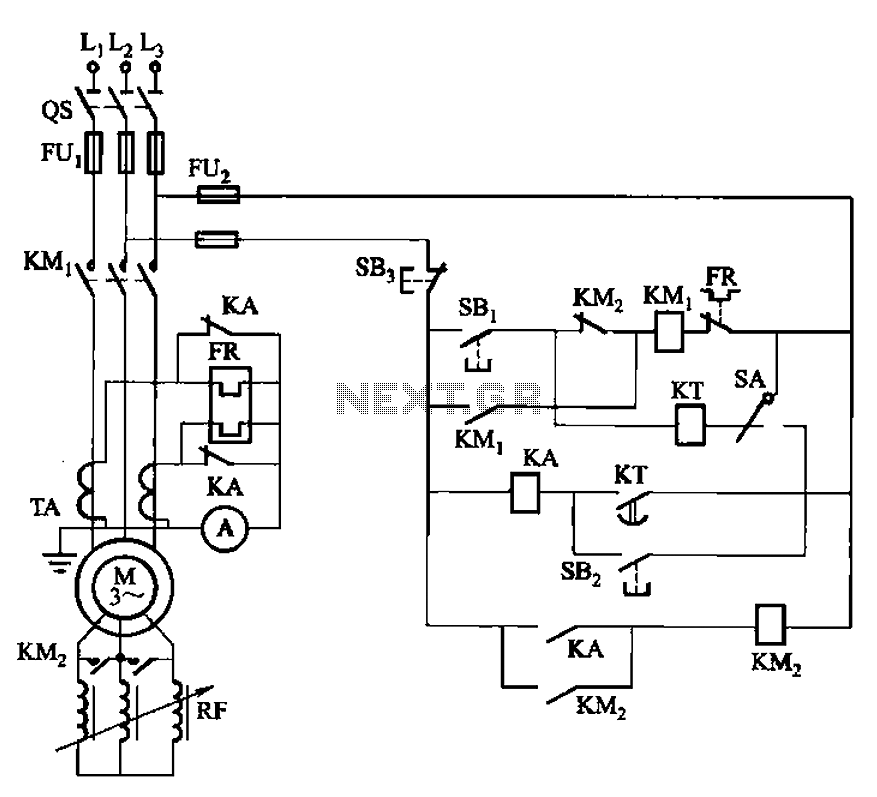

Frequency sensitive rheostat for manual and automatic way starting circuit

The circuit shown in Figure 3-164 can operate in both manual and automatic modes. During startup, the normally closed contact of relay KA is shorted, which affects the heating element to avoid prolonged startup times that could lead to thermal relay malfunctions and impact the boot process.

The circuit operates by utilizing a relay (KA) that has a normally closed contact configuration. In the manual mode, the user can initiate the heating element directly, while in the automatic mode, the circuit is designed to manage the heating element's operation based on predefined conditions.

At startup, the relay KA's normally closed contact ensures that the heating element is engaged immediately. This design choice is critical as it minimizes the startup time, which is essential for preventing the thermal relay from overheating or malfunctioning. The thermal relay is responsible for monitoring the temperature of the heating element and protecting the system from overheating. If the startup time is excessive, the thermal relay may trip, leading to a failure in the boot process.

In the circuit, various components work together to ensure safe and efficient operation. The relay KA is activated by a control signal that determines whether the circuit is in manual or automatic mode. Additional components may include fuses for overcurrent protection, temperature sensors for real-time monitoring, and control logic to switch between manual and automatic operations.

Overall, the design emphasizes reliability and efficiency, ensuring that the heating element operates within safe temperature limits while providing flexibility for user control. Proper implementation of this circuit can enhance the performance of heating applications, making it suitable for various industrial and commercial uses. Circuit shown in Figure 3-164. The circuit can be manual and automatic two ways. During startup, KA normally closed contact relay FR hot heating element shorted, in order to av oid start-up time is longer cause thermal relay malfunction affect the boot.

The circuit operates by utilizing a relay (KA) that has a normally closed contact configuration. In the manual mode, the user can initiate the heating element directly, while in the automatic mode, the circuit is designed to manage the heating element's operation based on predefined conditions.

At startup, the relay KA's normally closed contact ensures that the heating element is engaged immediately. This design choice is critical as it minimizes the startup time, which is essential for preventing the thermal relay from overheating or malfunctioning. The thermal relay is responsible for monitoring the temperature of the heating element and protecting the system from overheating. If the startup time is excessive, the thermal relay may trip, leading to a failure in the boot process.

In the circuit, various components work together to ensure safe and efficient operation. The relay KA is activated by a control signal that determines whether the circuit is in manual or automatic mode. Additional components may include fuses for overcurrent protection, temperature sensors for real-time monitoring, and control logic to switch between manual and automatic operations.

Overall, the design emphasizes reliability and efficiency, ensuring that the heating element operates within safe temperature limits while providing flexibility for user control. Proper implementation of this circuit can enhance the performance of heating applications, making it suitable for various industrial and commercial uses. Circuit shown in Figure 3-164. The circuit can be manual and automatic two ways. During startup, KA normally closed contact relay FR hot heating element shorted, in order to av oid start-up time is longer cause thermal relay malfunction affect the boot.