Generators

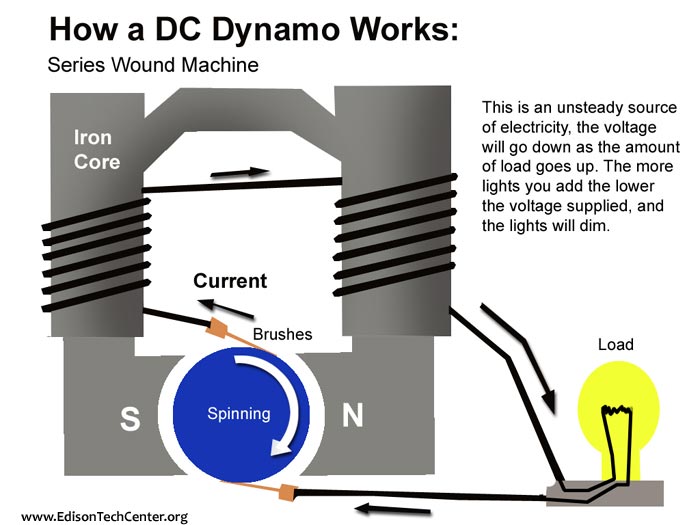

A mechanical power source is required, such as a turbine powered by falling water, a wind turbine, a gas turbine, or a steam turbine. A shaft from one of these devices is connected to a generator to produce power. Dynamos and generators operate based on the complex phenomena of electromagnetism. Understanding electromagnetism, its fields, and effects is a broad area of study. It took 60 years after Volta's first battery for a powerful dynamo to be developed. To simplify the introduction to power generation, a generator or dynamo can be understood as a magnet rotating within the influence of another magnet's magnetic field. A magnetic field is not visible but is often represented by lines of flux. A typical generator or dynamo consists of stationary magnets (the stator) that create a strong magnetic field and a rotating magnet (the rotor) that disturbs and intersects the magnetic lines of flux from the stator. When the rotor cuts through these lines, it generates electricity. According to Faraday's Law of Induction, moving a wire back and forth in a magnetic field induces a flow of electrons in the metal. Copper, which has 27 electrons, allows the last two in the outer orbit to be easily displaced to adjacent atoms, creating electrical flow. Utilizing a coil of wire enhances this flow. The generator's strength relies on the type of magnets used; typically, they are not made of natural magnetite or permanent magnets (except in small generators), but instead consist of copper or aluminum wire coiled around an iron core. Each coil must be energized to function as a magnet, forming a solenoid, which is significantly more powerful than natural magnetite. Small solenoids can generate strong magnetic fields. The coils in generators must be insulated to prevent failure due to excessive heat, which can lead to insulation breakdown and short circuits between parallel wires. The term "dynamo" refers to an older type of generator that produces direct current (DC) power, where electrons flow in one direction. A challenge with simple generators is that when the rotor completes a rotation, the current reverses. Early inventors faced difficulties with alternating current (AC), which is more complex to manage for motors and lighting. To capture only the positive energy from the generator, they invented a commutator, a switch that allows current to flow in one direction. Brushes, part of the commutator, must conduct electricity while maintaining contact with the rotating armature. Initially, these brushes were made of fine wire, which wore out quickly, leading to the development of graphite blocks for the same purpose. The stator is a fixed structure that generates the magnetic field; small dynamos can use permanent magnets, while larger ones require electromagnets. The armature consists of coiled copper windings that rotate within the magnetic field created by the stator. As the windings move, they intersect the magnetic field lines, producing pulses of electric power. The commutator is essential for generating direct current. In direct current systems, power flows in one direction through a wire. However, since the rotating armature in a dynamo reverses current every half-turn, the commutator acts as a rotary switch, disconnecting power during the reversed current phase. The magnets in a dynamo, being solenoids, require power to operate.

A generator or dynamo system is essential for converting mechanical energy into electrical energy. The mechanical power source, whether it be a turbine or another device, initiates the process by rotating a shaft that is mechanically linked to the generator. The generator's design is crucial for efficiency and effectiveness in power generation, utilizing principles of electromagnetism to induce electric current.

The arrangement of the stator and rotor is fundamental. The stator's magnetic field is created by either permanent magnets or electromagnets, depending on the size and application of the generator. A robust magnetic field enhances the efficiency of the energy conversion process. The rotor, equipped with coils of wire, is designed to rotate within this magnetic field, maximizing the interaction between the magnetic field and the coil windings.

Insulation of the wire coils is a critical aspect of generator design. High temperatures can lead to insulation breakdown, resulting in short circuits that can damage the generator and reduce its operational lifespan. Therefore, materials with high thermal resistance and electrical insulation properties are selected to ensure reliability.

The commutator and brushes play a vital role in converting the alternating current produced during the rotor's rotation into direct current. The design and materials used for brushes are selected to minimize wear and ensure a stable electrical connection throughout the operation. Advanced designs may employ modern materials and technologies to improve the longevity and performance of these components.

In summary, the generator or dynamo system is a sophisticated assembly that relies on the principles of electromagnetism to convert mechanical energy into electrical energy. The careful design of each component, from the power source to the stator, rotor, and commutator, ensures efficient and reliable power generation for various applications.First you need a mechanical power source like a turbine(powered by water falling), wind turbine, gas turbine or steam turbine. A shaft from one of these devices is connected to a generator to make power. Dynamos and generators work using the wild complex phenomena of electromagnetism. Understanding the behavior of electromagnetism, its fields and its effects is a large subject of study. There is a reason why it took 60 years AFTER Volta`s first battery to get a good powerful dynamo working. We will keep things simple to help introduce you to the interesting subject of power generation. In the most basic sense a generator/dynamo is one magnet rotating while inside the influence of another magnet`s magnetic field.

You cannot see a magnetic field, but it is often illustrated using lines of flux. In the illustration above lines of magnetic flux would follow the lines created by the iron filings. The generator/dynamo is made up of stationary magnets (stator) which create a powerful magnetic field, and a rotating magnet (rotor) which distorts and cuts through the magnetic lines of flux of the stator. When the rotor cuts through lines of magnetic flux it makes electricity. Due to Faraday`s Law of Induction if you take a wire and move it back and forth in a magnetic field, the field pushes on electrons in the metal.

Copper has 27 electrons, the last two in the orbit are easily pushed on to the next atom. This movement of electrons is electrical flow. If you take a lot of wire such as in a coil and move it in the field, you create a more powerful "flow" of electrons. The strength of your generator depends on: The magnets are usually not made of natural magnetite or a permanent magnet (unless it is a small generator), but they are copper or aluminum wire coiled around an iron core.

Each coil must be energized with some power to make it into a magnet. This coil around iron is called a solenoid. Solenoids are used instead of natural magnetite because the solenoid is MUCH more powerful. A small solenoid can create a very strong magnetic field. Above: The coils of wire in the generators must be insulated. Generator failure is caused by temperatures rising too high which results in a breakdown of insulation and a short between to parallel wires. Dynamo is an older term used to describe a generator that makes direct current power. DC power sends electrons in only one direction. The problem with a simple generator is that when the rotor rotates it eventually turns completely around, reversing the current.

Early inventors didn`t know what to do with this alternating current, alternating current is more complex to control and design motors and lights for. Early inventors had to figure a way to only capture the positive energy of the generator, so they invented a commutator.

The commutator is a switch that allows current to only flow in one direction. Brushes are part of the commutator, the brushes must conduct electricity as the keep contact with the rotating armature. The first brushes were actual wire "brushes" made of small wires. These wore out easily and they developed graphic blocks to do the same job. The stator is a fixed structure that makes magnetic field, you can do this in a small dynamo using a permanent magnet.

Large dynamos require an electromagnet. The armature is made of coiled copper windings which rotate inside the magnetic field made by the stator. When the windings move, they cut through the lines of magnetic field. This creates pulses of electric power. The commutator is needed to produce direct current. In direct current power flows in only one direction through a wire, the problem is that the rotating armature in a dynamo reverses current each half turn, so the commutator is a rotary switch that disconnects the power during the reversed current part of the cycle.

Since the magnets in an dynamo are solenoids, they must be powered to work. So in addition to bru 🔗 External reference

A generator or dynamo system is essential for converting mechanical energy into electrical energy. The mechanical power source, whether it be a turbine or another device, initiates the process by rotating a shaft that is mechanically linked to the generator. The generator's design is crucial for efficiency and effectiveness in power generation, utilizing principles of electromagnetism to induce electric current.

The arrangement of the stator and rotor is fundamental. The stator's magnetic field is created by either permanent magnets or electromagnets, depending on the size and application of the generator. A robust magnetic field enhances the efficiency of the energy conversion process. The rotor, equipped with coils of wire, is designed to rotate within this magnetic field, maximizing the interaction between the magnetic field and the coil windings.

Insulation of the wire coils is a critical aspect of generator design. High temperatures can lead to insulation breakdown, resulting in short circuits that can damage the generator and reduce its operational lifespan. Therefore, materials with high thermal resistance and electrical insulation properties are selected to ensure reliability.

The commutator and brushes play a vital role in converting the alternating current produced during the rotor's rotation into direct current. The design and materials used for brushes are selected to minimize wear and ensure a stable electrical connection throughout the operation. Advanced designs may employ modern materials and technologies to improve the longevity and performance of these components.

In summary, the generator or dynamo system is a sophisticated assembly that relies on the principles of electromagnetism to convert mechanical energy into electrical energy. The careful design of each component, from the power source to the stator, rotor, and commutator, ensures efficient and reliable power generation for various applications.First you need a mechanical power source like a turbine(powered by water falling), wind turbine, gas turbine or steam turbine. A shaft from one of these devices is connected to a generator to make power. Dynamos and generators work using the wild complex phenomena of electromagnetism. Understanding the behavior of electromagnetism, its fields and its effects is a large subject of study. There is a reason why it took 60 years AFTER Volta`s first battery to get a good powerful dynamo working. We will keep things simple to help introduce you to the interesting subject of power generation. In the most basic sense a generator/dynamo is one magnet rotating while inside the influence of another magnet`s magnetic field.

You cannot see a magnetic field, but it is often illustrated using lines of flux. In the illustration above lines of magnetic flux would follow the lines created by the iron filings. The generator/dynamo is made up of stationary magnets (stator) which create a powerful magnetic field, and a rotating magnet (rotor) which distorts and cuts through the magnetic lines of flux of the stator. When the rotor cuts through lines of magnetic flux it makes electricity. Due to Faraday`s Law of Induction if you take a wire and move it back and forth in a magnetic field, the field pushes on electrons in the metal.

Copper has 27 electrons, the last two in the orbit are easily pushed on to the next atom. This movement of electrons is electrical flow. If you take a lot of wire such as in a coil and move it in the field, you create a more powerful "flow" of electrons. The strength of your generator depends on: The magnets are usually not made of natural magnetite or a permanent magnet (unless it is a small generator), but they are copper or aluminum wire coiled around an iron core.

Each coil must be energized with some power to make it into a magnet. This coil around iron is called a solenoid. Solenoids are used instead of natural magnetite because the solenoid is MUCH more powerful. A small solenoid can create a very strong magnetic field. Above: The coils of wire in the generators must be insulated. Generator failure is caused by temperatures rising too high which results in a breakdown of insulation and a short between to parallel wires. Dynamo is an older term used to describe a generator that makes direct current power. DC power sends electrons in only one direction. The problem with a simple generator is that when the rotor rotates it eventually turns completely around, reversing the current.

Early inventors didn`t know what to do with this alternating current, alternating current is more complex to control and design motors and lights for. Early inventors had to figure a way to only capture the positive energy of the generator, so they invented a commutator.

The commutator is a switch that allows current to only flow in one direction. Brushes are part of the commutator, the brushes must conduct electricity as the keep contact with the rotating armature. The first brushes were actual wire "brushes" made of small wires. These wore out easily and they developed graphic blocks to do the same job. The stator is a fixed structure that makes magnetic field, you can do this in a small dynamo using a permanent magnet.

Large dynamos require an electromagnet. The armature is made of coiled copper windings which rotate inside the magnetic field made by the stator. When the windings move, they cut through the lines of magnetic field. This creates pulses of electric power. The commutator is needed to produce direct current. In direct current power flows in only one direction through a wire, the problem is that the rotating armature in a dynamo reverses current each half turn, so the commutator is a rotary switch that disconnects the power during the reversed current part of the cycle.

Since the magnets in an dynamo are solenoids, they must be powered to work. So in addition to bru 🔗 External reference