Good vibrations for energy harvesting

A wide range of low-power industrial sensors and controllers are turning to alternative sources of energy as the primary or supplemental means of supplying power. Ideally, such harvested energy will eliminate the need for wired power or batteries altogether. Transducers that generate electricity from readily available physical sources such as temperature differentials (thermoelectric generators or thermopiles), mechanical vibration or strain (piezoelectric or electromechanical devices), and light (photovoltaic devices) are becoming viable power sources for many applications. Numerous wireless sensors, remote monitors, and other low-power applications are on track to become near-zero-power devices using harvested energy only (commonly referred to as nanopower). Although energy harvesting has been emerging since the early 2000s, recent technological developments have pushed it to the point of commercial viability. In 2010, the field is at an inflection point and poised for growth. Building-automation sensor applications using energy-harvesting techniques have already been deployed in Europe, indicating that the growth stage may already be underway. Even though the concept of energy harvesting has existed for several years, implementing a system in a real-world environment has been cumbersome, complex, and costly. Markets where energy-harvesting approaches have been utilized include transportation infrastructure, wireless medical devices, tire pressure sensing, and building automation. In building automation, systems such as occupancy sensors, thermostats, and light switches can eliminate the power or control wiring typically required and instead use a mechanical or energy-harvesting system. Similarly, a wireless network employing energy-harvesting techniques can link multiple sensors within a building, reducing heating, ventilation, and air-conditioning (HVAC) and lighting costs by turning off power to non-essential areas when the building is unoccupied. Furthermore, the cost of energy-harvesting electronics is often lower than that of running supply wires, presenting a clear economic advantage for adopting harvested power techniques. A typical energy scavenging configuration usually consists of a free energy source, such as a piezoelectric transducer attached to a vibrating mechanical source, like an HVAC duct or a window pane. These small piezoelectric devices can convert small vibrations or strain differences into electrical energy. This electrical energy can then be converted by an energy-harvesting circuit into a usable form to power downstream circuits. These downstream electronics typically consist of some kind of sensor, an analog-to-digital converter, and an ultra-low-power microcontroller. These components can utilize the harvested energy to activate a sensor for data collection, which can then be transmitted using an ultra-low-power wireless transceiver. Each circuit block in this chain, with the possible exception of the energy source itself, has faced unique constraints that have hindered its economic viability until now. Low-cost and low-power sensors and microcontrollers have been available for several years; however, ultra-low-power transceivers have only recently become commercially available. The laggard in this chain has been the energy harvester, with existing implementations typically consisting of low-performing discrete configurations of 30 components or more. Such designs exhibit low conversion efficiency and high quiescent currents, which compromise end system performance. Low conversion efficiency increases the time required to power up a system, consequently extending the time interval between sensor readings and data transmission. High quiescent currents limit the output of the energy-harvesting source, as it must first supply the current needed for its operation before providing excess power. A highly integrated, high-efficiency DC/DC buck converter with a low-loss full-wave bridge rectifier that can harvest and manage piezoelectric energy from a vibration or strain source has been lacking. However, Linear Technology's LTC3588-1 piezoelectric energy-harvesting power supply significantly simplifies the task of harvesting surplus energy from such sources. The circuit employs a small piezoelectric transducer to convert mechanical vibration into an AC voltage source, which is fed into the LTC3588-1's internal bridge rectifier. This device can harvest small vibration sources and generate system power instead of relying on traditional battery power. The LTC3588-1 is an ultra-low-quiescent-current power supply designed specifically for energy-harvesting and low-current step-down applications. It can interface directly with a piezoelectric or alternative AC power source, rectify the voltage waveform, and store harvested energy in an external capacitor, while managing excess power through an internal shunt regulator and maintaining a regulated output voltage via a nanopower high-efficiency buck regulator. The internal full-wave bridge rectifier is accessible through two differential inputs, PZ1 and PZ2, which rectify AC inputs. The rectified output is then stored on a capacitor at the VIN pin, serving as an energy reservoir for the buck converter. The low-loss bridge rectifier has a total voltage drop of approximately 400 mV with typical piezo-generated currents around 10 µA, and it can handle currents up to 50 mA. The buck regulator is activated once sufficient voltage is present on VIN to produce a regulated output. It employs a hysteretic voltage algorithm for output control through internal feedback from the VOUT sense pin. The buck converter charges an output capacitor through an inductor to a value slightly above the regulation point by ramping the inductor current to 260 mA through an internal PMOS switch and then ramping it down to 0 mA through an internal NMOS switch, efficiently delivering energy to the output capacitor. Its hysteretic method reduces losses associated with FET switching and maintains output at light loads. The buck converter provides a minimum of 100 mA of average load current during switching. The introduction of the LTC3588-1 piezoelectric energy-harvesting power supply, featuring an integrated low-loss full-wave bridge rectifier, marks a significant advancement in the design of effective energy-harvesting systems. This device can extract energy from nearly any source of mechanical vibration or strain, simplifying the power conversion design aspects of an energy-harvesting chain. This development offers an advantageous solution for system designers, enabling the utilization of mechanical vibrations to power energy-harvesting systems without the traditional configuration challenges.A wide range of low-power industrial sensors and controllers are turning to alternative sources of energy as the primary or supplemental means of supplying power. Ideally, such harvested energy will eliminate the need for wired power or batteries altogether. Transducers that create electricity from readily available physical sources such as temper ature differentials (thermoelectric generators or thermopiles), mechanical vibration or strain (piezoelectric or electromechanical devices) and light (photovoltaic devices) are becoming viable sources of power for many applications. Numerous wireless sensors, remote monitors, and other low-power applications are on track to become near-zero-power devices using harvested energy only (commonly referred to by some as nanopower).

Although energy harvesting has been emerging since early 2000 (its embryonic phase), recent technology developments have pushed it to the point of commercial viability. In short, in 2010 we are at an inflection point and are poised for the commencement of the growth phase.

Building-automation sensor applications using energy-harvesting techniques have already been deployed in Europe, illustrating that the growth stage may already be underway. Even though the The concept of energy harvesting has been around for a number of years, the implementation of a system in a real world environment has been cumbersome, complex and costly.

Nevertheless, examples of markets where an energy-harvesting approach has been used include transportation infrastructure, wireless medical devices, tire pressure sensing, and the largest so far, building automation. In the case of building automation, systems such as occupancy sensors, thermostats and light switches can eliminate the power or control wiring normally required and use a mechanical or energy-harvesting system instead.

Similarly, a wireless network using an energy-harvesting technique can link any number of sensors together in a building to reduce heating, ventilation, and air-conditioning (HVAC) and lighting costs by turning off power to non-essential areas when the building has no occupants. Furthermore, the cost of energy-harvesting electronics is often lower than running supply wires, so there is clearly an economic gain to be had by adopting a harvested power technique.

A typical energy scavenging configuration or system, (represented by the four main circuit system blocks shown in Fig. 1), usually consists of a free energy source such as a piezoelectric transducer attached to a vibrating mechanical source such as an HVAC duct or a window pane.

These small piezoelectric devices can convert small vibrations or strain differences into electrical energy. This electrical energy can then be converted by an energy-harvesting circuit (the second block in Fig.

1) and modified into a usable form to power downstream circuits. These downstream electronics will usually consist of some kind of sensor, analog-to-digital converter and an ultra-low-power microcontroller (the third block in Fig. 1). These components can take this harvested energy, now in the form of an electric current, and wake up a sensor to take a reading or a measurement then make this data available for transmission via an ultra-low-power wireless transceiver represented by the fourth block in the circuit chain shown in Fig.

1. Each circuit system block in this chain, with the possible exception of the energy source itself has had its own unique set of constraints that have impaired its economical viability until now. Low cost and low power sensors and microcontrollers have been available for a couple of years or so; however, it is only recently that ultra-low-power transceivers have become commercially available.

Nevertheless, the laggard in this chain has been the energy harvester. Existing implementations of the energy harvester block typically consist of low performing discrete configurations, usually comprising of 30 components or more. Such designs have low conversion efficiency and high quiescent currents. Both of these deficiencies result in compromised performance in an end system. The low conversion efficiency will increase the amount of time required to power up a system, which in turn increases the time interval between taking a sensor reading and transmitting this data.

A high quiescent current limits how low the output of the energy-harvesting source can be, since it must first overcome the current level needed for its own operation before it can supply any excess power to the output. What has been missing until now has been a highly integrated, high-efficiency dc/dc buck converter with low-loss full-wave bridge rectifier that can both harvest and manage the piezoelectric energy from a vibration or strain source.

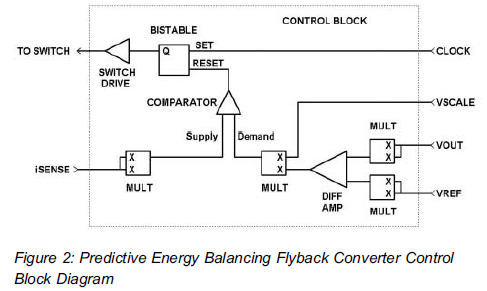

However, Linear Technology`s new LTC3588-1 piezoelectric energy-harvesting power supply greatly simplifies the task of harvesting surplus energy from such sources. The circuit shown in Fig. 2 uses a small piezoelectric transducer to convert mechanical vibration into an ac voltage source that is fed into the LTC3588-1`s internal bridge rectifier.

It can harvest small vibration sources and generate system power instead of using traditional battery power. The LTC3588-1 is an ultra-low-quiescent-current power supply designed specifically for energy-harvesting and/or low-current step-down applications.

It can interface directly to a piezoelectric or alternative ac power source, rectify the voltage waveform and store harvested energy on to an external capacitor, bleed off any excess power via an internal shunt regulator and maintain a regulated output voltage be means of a nanopower high-efficiency buck regulator. The LTC3588-1`s internal full-wave bridge rectifier is accessible via two differential inputs, PZ1 and PZ2 that rectifies ac inputs.

This rectified output is then stored on a capacitor at the VIN pin and can be used as an energy reservoir for the buck converter. The low-loss bridge rectifier has a total voltage drop of about 400 mV with typical Piezo generate currents, which are normally around 10 µA.

This bridge can carry up to 50-mA current. The buck regulator is enabled once there is sufficient voltage on VIN to produce a regulated output. The buck regulator uses a hysteretic voltage algorithm to control the output through internal feedback from the VOUT sense pin. The buck converter charges an output capacitor through an inductor to a value slightly higher than the regulation point.

It does this by ramping the inductor current to 260 mA through an internal PMOS switch and then ramping it down to 0 mA through an internal NMOS switch, thereby efficiently delivering energy to the output capacitor. Its hysteretic method of providing a regulated output reduces losses associated with FET switching and maintains an output at light loads.

The buck converter delivers a minimum of 100 mA of average load current when it is switching. With analog switch-mode power supply design expertise in short supply around the globe, it has been difficult to design an effective energy-harvesting system as illustrated in Fig. 1. However, with the introduction of the LTC3588-1 piezoelectric energy-harvesting power supply, with integrated low-loss full-wave bridge rectifier, that`s all about to change.

This revolutionary device can extract energy from almost any source of mechanical vibration or strain. Furthermore, with its comprehensive feature set and ease of design, it simplifies the hard-to-do power conversion design aspects of an energy-harvesting chain.

This is good news for the system designer because these good vibrations can be used to power the energy-harvesting system, instead of having to deal with the traditional configuration headaches. – 🔗 External reference

Although energy harvesting has been emerging since early 2000 (its embryonic phase), recent technology developments have pushed it to the point of commercial viability. In short, in 2010 we are at an inflection point and are poised for the commencement of the growth phase.

Building-automation sensor applications using energy-harvesting techniques have already been deployed in Europe, illustrating that the growth stage may already be underway. Even though the The concept of energy harvesting has been around for a number of years, the implementation of a system in a real world environment has been cumbersome, complex and costly.

Nevertheless, examples of markets where an energy-harvesting approach has been used include transportation infrastructure, wireless medical devices, tire pressure sensing, and the largest so far, building automation. In the case of building automation, systems such as occupancy sensors, thermostats and light switches can eliminate the power or control wiring normally required and use a mechanical or energy-harvesting system instead.

Similarly, a wireless network using an energy-harvesting technique can link any number of sensors together in a building to reduce heating, ventilation, and air-conditioning (HVAC) and lighting costs by turning off power to non-essential areas when the building has no occupants. Furthermore, the cost of energy-harvesting electronics is often lower than running supply wires, so there is clearly an economic gain to be had by adopting a harvested power technique.

A typical energy scavenging configuration or system, (represented by the four main circuit system blocks shown in Fig. 1), usually consists of a free energy source such as a piezoelectric transducer attached to a vibrating mechanical source such as an HVAC duct or a window pane.

These small piezoelectric devices can convert small vibrations or strain differences into electrical energy. This electrical energy can then be converted by an energy-harvesting circuit (the second block in Fig.

1) and modified into a usable form to power downstream circuits. These downstream electronics will usually consist of some kind of sensor, analog-to-digital converter and an ultra-low-power microcontroller (the third block in Fig. 1). These components can take this harvested energy, now in the form of an electric current, and wake up a sensor to take a reading or a measurement then make this data available for transmission via an ultra-low-power wireless transceiver represented by the fourth block in the circuit chain shown in Fig.

1. Each circuit system block in this chain, with the possible exception of the energy source itself has had its own unique set of constraints that have impaired its economical viability until now. Low cost and low power sensors and microcontrollers have been available for a couple of years or so; however, it is only recently that ultra-low-power transceivers have become commercially available.

Nevertheless, the laggard in this chain has been the energy harvester. Existing implementations of the energy harvester block typically consist of low performing discrete configurations, usually comprising of 30 components or more. Such designs have low conversion efficiency and high quiescent currents. Both of these deficiencies result in compromised performance in an end system. The low conversion efficiency will increase the amount of time required to power up a system, which in turn increases the time interval between taking a sensor reading and transmitting this data.

A high quiescent current limits how low the output of the energy-harvesting source can be, since it must first overcome the current level needed for its own operation before it can supply any excess power to the output. What has been missing until now has been a highly integrated, high-efficiency dc/dc buck converter with low-loss full-wave bridge rectifier that can both harvest and manage the piezoelectric energy from a vibration or strain source.

However, Linear Technology`s new LTC3588-1 piezoelectric energy-harvesting power supply greatly simplifies the task of harvesting surplus energy from such sources. The circuit shown in Fig. 2 uses a small piezoelectric transducer to convert mechanical vibration into an ac voltage source that is fed into the LTC3588-1`s internal bridge rectifier.

It can harvest small vibration sources and generate system power instead of using traditional battery power. The LTC3588-1 is an ultra-low-quiescent-current power supply designed specifically for energy-harvesting and/or low-current step-down applications.

It can interface directly to a piezoelectric or alternative ac power source, rectify the voltage waveform and store harvested energy on to an external capacitor, bleed off any excess power via an internal shunt regulator and maintain a regulated output voltage be means of a nanopower high-efficiency buck regulator. The LTC3588-1`s internal full-wave bridge rectifier is accessible via two differential inputs, PZ1 and PZ2 that rectifies ac inputs.

This rectified output is then stored on a capacitor at the VIN pin and can be used as an energy reservoir for the buck converter. The low-loss bridge rectifier has a total voltage drop of about 400 mV with typical Piezo generate currents, which are normally around 10 µA.

This bridge can carry up to 50-mA current. The buck regulator is enabled once there is sufficient voltage on VIN to produce a regulated output. The buck regulator uses a hysteretic voltage algorithm to control the output through internal feedback from the VOUT sense pin. The buck converter charges an output capacitor through an inductor to a value slightly higher than the regulation point.

It does this by ramping the inductor current to 260 mA through an internal PMOS switch and then ramping it down to 0 mA through an internal NMOS switch, thereby efficiently delivering energy to the output capacitor. Its hysteretic method of providing a regulated output reduces losses associated with FET switching and maintains an output at light loads.

The buck converter delivers a minimum of 100 mA of average load current when it is switching. With analog switch-mode power supply design expertise in short supply around the globe, it has been difficult to design an effective energy-harvesting system as illustrated in Fig. 1. However, with the introduction of the LTC3588-1 piezoelectric energy-harvesting power supply, with integrated low-loss full-wave bridge rectifier, that`s all about to change.

This revolutionary device can extract energy from almost any source of mechanical vibration or strain. Furthermore, with its comprehensive feature set and ease of design, it simplifies the hard-to-do power conversion design aspects of an energy-harvesting chain.

This is good news for the system designer because these good vibrations can be used to power the energy-harvesting system, instead of having to deal with the traditional configuration headaches. – 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713