How to Make a 25 Amp 1500 watts Heater Controller Circuit

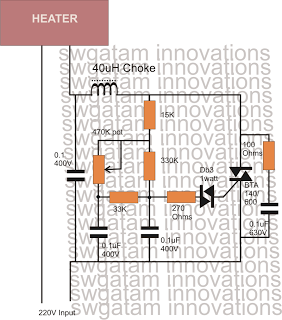

Controlling heaters rated up to 1500 watts requires stringent specifications for the controlling unit to ensure safe and effective operation. The introduction of advanced snubber-less Triacs and Diacs has made it relatively easier to implement heater controllers at high wattage levels. The circuit setup is standard, resembling the wiring typically used in conventional light dimmer switch circuits. The associated network of resistors and capacitors with the Diac is selected to ensure that the Diac only fires when the sine wave falls below a specific voltage level. This selective conduction of the Triac for a designated portion of the input sine voltage results in an output across the Triac that chops the AC waveform into smaller segments, effectively lowering the RMS value of the resultant voltage, depending on the values of the surrounding resistors and capacitors. The potentiometer shown in the circuit diagram is utilized to control the heater element, initiating the aforementioned process. A higher resistance value increases the time required for the capacitor to charge and discharge, thereby extending the firing duration of the Diac/Triac pair. This extension keeps the Triac and the load switched off for a longer duration of the AC sine wave, resulting in a lower average voltage supplied to the heater and consequently maintaining a cooler temperature. Conversely, adjusting the potentiometer to a lower resistance allows the capacitor to charge and discharge more rapidly, accelerating the cycle and increasing the average switching period of the Triac. This results in a higher average voltage across the heater, generating more heat.

The heater control circuit operates by utilizing a Triac and Diac in conjunction with a resistive-capacitive (RC) network. The RC network is crucial for timing the firing of the Diac, which in turn triggers the Triac. The Diac remains off until the voltage across it exceeds its breakover voltage, which is determined by the values of the resistors and capacitors in the network. When the Diac fires, it allows current to flow through the Triac, effectively turning on the heater.

The potentiometer serves as a variable resistor that adjusts the charging time of the capacitor in the RC network. By increasing the resistance, the charging time of the capacitor is prolonged, which delays the firing of the Diac. This results in a shorter conduction time for the Triac during each AC cycle, thereby reducing the average power delivered to the heater. The relationship between the potentiometer setting and the heater output is linear; as the resistance decreases, the capacitor charges faster, resulting in more frequent triggering of the Triac and a corresponding increase in the average voltage supplied to the heater.

This method of phase control allows for precise temperature regulation of the heating element, making it suitable for applications where temperature control is critical. The circuit can be designed to handle high power levels while maintaining safety standards, ensuring that the components can withstand the thermal and electrical stresses associated with high-wattage operation. Proper heat sinking for the Triac is also essential to prevent overheating during operation.Controlling heaters rated as high as 1500 watt requires stringent specifications with the controlling unit for safe and effective implementation of the intended operations. With the advent of advanced snubber-less Triacs and Diacs makingheatercontrollers at massive watt levels has become relatively easier today.

The set up of the circuit is pretty standard as the the wiring is very similar to the ones which are normally employed in ordinary light dimmer switch circuits. The following network resistors and capacitors associated with the diac are chosen such that they allow the diac to fire only as long as the sine curve remains below a certain voltage level.

The above conduction of the triac only for a specifiedsectionof the input sine voltage curve, results in an output across the triac which has the AC chopped into smaller sections, making the overall RMS of the resultant drop to a lower value, depending upon the values of the relevant resistors and capacitors around the diac. The pot which is shown in the figure is used forcontrollingthe heaterelementwhich initiates the above explained procedure.

The greater the resistance, the longer it takes or the capacitor to charge and discharge whih in turn prolongs the firing of the diac/triac pair. This prolongation keeps the triac and the load switched OFF for a longer section of the AC sine curve which results correspondingly lower average voltage to the heater, and the heatertemperatureremains at the cooler side.

Conversely when the pot is adjusted toward toproducea lower resistance, the capacitor charge and discharge at a faster rate making the abovecyclerapid which in turn keeps the average switching period of the triac at the higher side, resulting a higher average voltage to the heater. The heater now generates more heat due to the increased averagevoltagedevelopedacross it via the triac.

🔗 External reference

The heater control circuit operates by utilizing a Triac and Diac in conjunction with a resistive-capacitive (RC) network. The RC network is crucial for timing the firing of the Diac, which in turn triggers the Triac. The Diac remains off until the voltage across it exceeds its breakover voltage, which is determined by the values of the resistors and capacitors in the network. When the Diac fires, it allows current to flow through the Triac, effectively turning on the heater.

The potentiometer serves as a variable resistor that adjusts the charging time of the capacitor in the RC network. By increasing the resistance, the charging time of the capacitor is prolonged, which delays the firing of the Diac. This results in a shorter conduction time for the Triac during each AC cycle, thereby reducing the average power delivered to the heater. The relationship between the potentiometer setting and the heater output is linear; as the resistance decreases, the capacitor charges faster, resulting in more frequent triggering of the Triac and a corresponding increase in the average voltage supplied to the heater.

This method of phase control allows for precise temperature regulation of the heating element, making it suitable for applications where temperature control is critical. The circuit can be designed to handle high power levels while maintaining safety standards, ensuring that the components can withstand the thermal and electrical stresses associated with high-wattage operation. Proper heat sinking for the Triac is also essential to prevent overheating during operation.Controlling heaters rated as high as 1500 watt requires stringent specifications with the controlling unit for safe and effective implementation of the intended operations. With the advent of advanced snubber-less Triacs and Diacs makingheatercontrollers at massive watt levels has become relatively easier today.

The set up of the circuit is pretty standard as the the wiring is very similar to the ones which are normally employed in ordinary light dimmer switch circuits. The following network resistors and capacitors associated with the diac are chosen such that they allow the diac to fire only as long as the sine curve remains below a certain voltage level.

The above conduction of the triac only for a specifiedsectionof the input sine voltage curve, results in an output across the triac which has the AC chopped into smaller sections, making the overall RMS of the resultant drop to a lower value, depending upon the values of the relevant resistors and capacitors around the diac. The pot which is shown in the figure is used forcontrollingthe heaterelementwhich initiates the above explained procedure.

The greater the resistance, the longer it takes or the capacitor to charge and discharge whih in turn prolongs the firing of the diac/triac pair. This prolongation keeps the triac and the load switched OFF for a longer section of the AC sine curve which results correspondingly lower average voltage to the heater, and the heatertemperatureremains at the cooler side.

Conversely when the pot is adjusted toward toproducea lower resistance, the capacitor charge and discharge at a faster rate making the abovecyclerapid which in turn keeps the average switching period of the triac at the higher side, resulting a higher average voltage to the heater. The heater now generates more heat due to the increased averagevoltagedevelopedacross it via the triac.

🔗 External reference