Irons intelligent control circuit

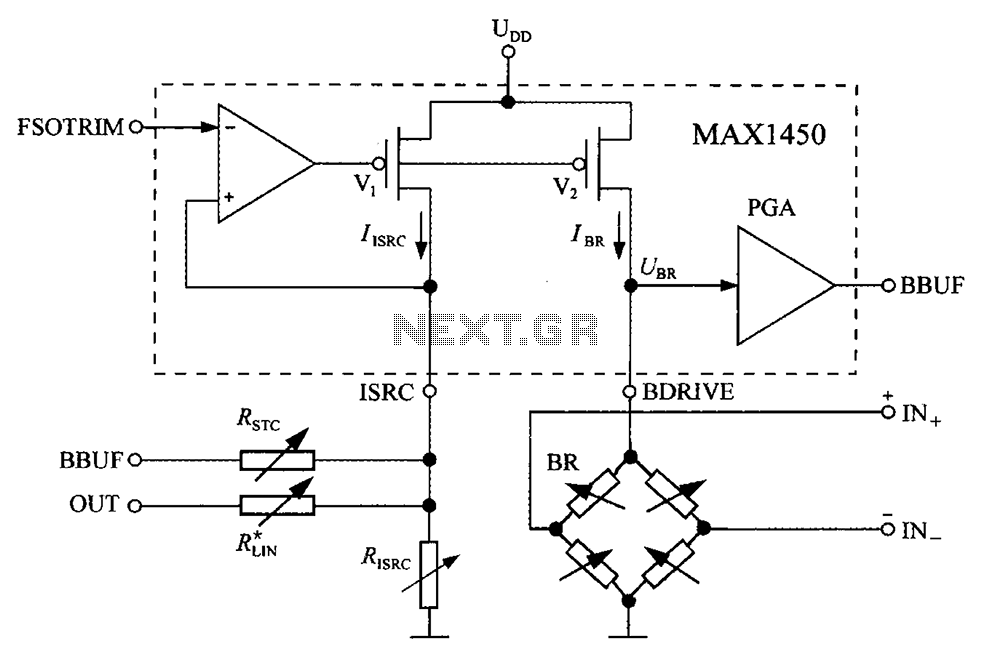

The intelligent control circuit for the iron is presented. This circuit utilizes the integrated circuit PT8A351X to manage functions such as direction detection, relay control, and LED indication. When the iron is positioned horizontally, it will power off after 30 seconds. Conversely, when the iron is held vertically, the pin is grounded, and the iron will automatically turn off after approximately 10 minutes.

The intelligent control circuit for the iron employs the PT8A351X integrated circuit, which serves as the core component for managing the operational features of the device. The circuit is designed to enhance user safety and energy efficiency by integrating direction detection and automatic shut-off functionalities.

The direction detection is achieved through a switch that identifies the orientation of the iron. When the iron is placed horizontally, the circuit triggers a timer that counts down from 30 seconds. If the iron remains in this position without any user intervention, the relay is activated to cut off power to the heating element, thereby preventing overheating and potential hazards.

In the vertical position, the control circuit operates differently. The grounding of a specific pin indicates that the iron is upright. In this state, the circuit is designed to remain operational for an extended period, specifically about 10 minutes, before automatically shutting off. This feature is particularly useful for users who may need to pause briefly while using the iron without the immediate risk of it becoming a fire hazard.

Additionally, the LED control integrated into the circuit provides visual feedback to the user regarding the status of the iron. It can indicate when the iron is heating, when it has powered off, and if there are any operational errors. This user-friendly feature enhances the overall usability of the iron, making it safer and more efficient.

In summary, the intelligent control circuit for the iron, powered by the PT8A351X, incorporates advanced features such as orientation detection, automatic shut-off after specified time intervals, and LED status indication, all contributing to a safer and more efficient ironing experience.The iron intelligent control circuit shown. In this circuit, the integrated circuit PT8A351X, irons by placing direction detection identification switch, relay and LED control, when the iron horizontally, @ feet high, iron after 30 seconds from Power Off ; when the iron vertically, @ pin is low (ground), iron about 10 minutes off automatically.

The intelligent control circuit for the iron employs the PT8A351X integrated circuit, which serves as the core component for managing the operational features of the device. The circuit is designed to enhance user safety and energy efficiency by integrating direction detection and automatic shut-off functionalities.

The direction detection is achieved through a switch that identifies the orientation of the iron. When the iron is placed horizontally, the circuit triggers a timer that counts down from 30 seconds. If the iron remains in this position without any user intervention, the relay is activated to cut off power to the heating element, thereby preventing overheating and potential hazards.

In the vertical position, the control circuit operates differently. The grounding of a specific pin indicates that the iron is upright. In this state, the circuit is designed to remain operational for an extended period, specifically about 10 minutes, before automatically shutting off. This feature is particularly useful for users who may need to pause briefly while using the iron without the immediate risk of it becoming a fire hazard.

Additionally, the LED control integrated into the circuit provides visual feedback to the user regarding the status of the iron. It can indicate when the iron is heating, when it has powered off, and if there are any operational errors. This user-friendly feature enhances the overall usability of the iron, making it safer and more efficient.

In summary, the intelligent control circuit for the iron, powered by the PT8A351X, incorporates advanced features such as orientation detection, automatic shut-off after specified time intervals, and LED status indication, all contributing to a safer and more efficient ironing experience.The iron intelligent control circuit shown. In this circuit, the integrated circuit PT8A351X, irons by placing direction detection identification switch, relay and LED control, when the iron horizontally, @ feet high, iron after 30 seconds from Power Off ; when the iron vertically, @ pin is low (ground), iron about 10 minutes off automatically.