Arduino How to control a Servo

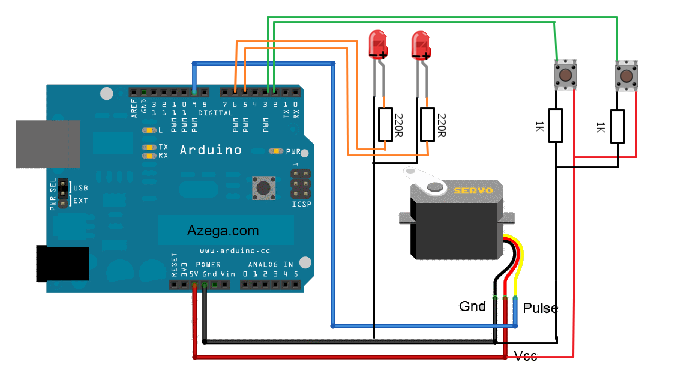

A servo motor is programmed to be controlled by two buttons; one button rotates the servo to the left and the other button rotates it to the right. When the servo is in motion, an LED corresponding to the direction of movement will illuminate to indicate the operation. The built-in library for controlling servos in Arduino simplifies the implementation of this project. Additionally, a servo will be utilized to continuously rotate an infrared (IR) sensor.

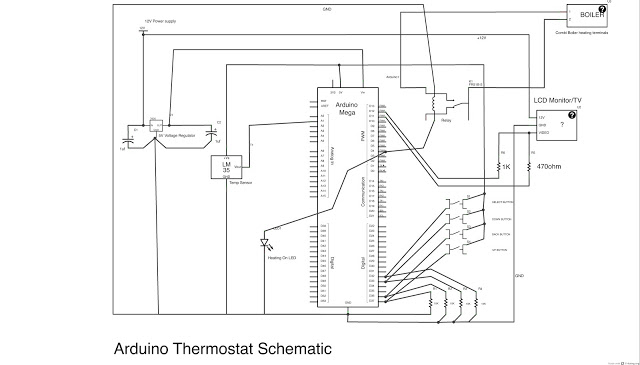

In this circuit design, the primary components include an Arduino microcontroller, a servo motor, two momentary push buttons, an LED indicator, and an IR sensor. The Arduino serves as the control unit, executing the logic for button presses and managing the servo's position.

The circuit configuration involves connecting the two push buttons to digital input pins on the Arduino. When a button is pressed, it sends a signal to the Arduino, which then determines the direction of the servo's rotation. The left button is connected to one digital pin, while the right button is connected to another. Each button should also have a pull-down resistor to ensure a stable low signal when the button is not pressed.

The servo motor is connected to a PWM-capable pin on the Arduino. The Arduino's servo library allows for easy control of the motor's angle, typically ranging from 0 to 180 degrees. The corresponding LED indicators are connected to separate digital output pins, and their state is controlled by the Arduino based on the button pressed.

The IR sensor, which is also connected to the Arduino, can be powered through one of the Arduino's output pins. This sensor will be mounted on the servo, allowing it to sweep continuously as the servo rotates. The data from the IR sensor can be processed to detect obstacles or measure distance, depending on the application.

This circuit design not only demonstrates basic control of a servo motor but also integrates sensor functionality, showcasing the versatility of Arduino in handling multiple input and output devices simultaneously. The use of LED indicators provides visual feedback, enhancing the user experience by clearly showing the direction of the servo's movement. Careful attention should be paid to the power requirements of the servo and the IR sensor to ensure stable operation within the circuit.In this one, servo is programmed to be controlled by two buttons, one turns servo to the left and the other one turns it to the right. When the servo is turning, corresponding LED will be switched on to indicate the operation. Because Arduino has built-in library for controlling servo, which makes servo a really easy kit to use.

In this project, I will be using a servo to turn the IR sensor around constantly. 🔗 External reference

In this circuit design, the primary components include an Arduino microcontroller, a servo motor, two momentary push buttons, an LED indicator, and an IR sensor. The Arduino serves as the control unit, executing the logic for button presses and managing the servo's position.

The circuit configuration involves connecting the two push buttons to digital input pins on the Arduino. When a button is pressed, it sends a signal to the Arduino, which then determines the direction of the servo's rotation. The left button is connected to one digital pin, while the right button is connected to another. Each button should also have a pull-down resistor to ensure a stable low signal when the button is not pressed.

The servo motor is connected to a PWM-capable pin on the Arduino. The Arduino's servo library allows for easy control of the motor's angle, typically ranging from 0 to 180 degrees. The corresponding LED indicators are connected to separate digital output pins, and their state is controlled by the Arduino based on the button pressed.

The IR sensor, which is also connected to the Arduino, can be powered through one of the Arduino's output pins. This sensor will be mounted on the servo, allowing it to sweep continuously as the servo rotates. The data from the IR sensor can be processed to detect obstacles or measure distance, depending on the application.

This circuit design not only demonstrates basic control of a servo motor but also integrates sensor functionality, showcasing the versatility of Arduino in handling multiple input and output devices simultaneously. The use of LED indicators provides visual feedback, enhancing the user experience by clearly showing the direction of the servo's movement. Careful attention should be paid to the power requirements of the servo and the IR sensor to ensure stable operation within the circuit.In this one, servo is programmed to be controlled by two buttons, one turns servo to the left and the other one turns it to the right. When the servo is turning, corresponding LED will be switched on to indicate the operation. Because Arduino has built-in library for controlling servo, which makes servo a really easy kit to use.

In this project, I will be using a servo to turn the IR sensor around constantly. 🔗 External reference