l293d interfacing with microcontroller

DC motor interfacing with a microcontroller using the L293D H-bridge and a transistor-based H-bridge. DC motor speed control is achieved through PWM. The DC motor is interfaced with 8051, AVR, and PIC microcontrollers.

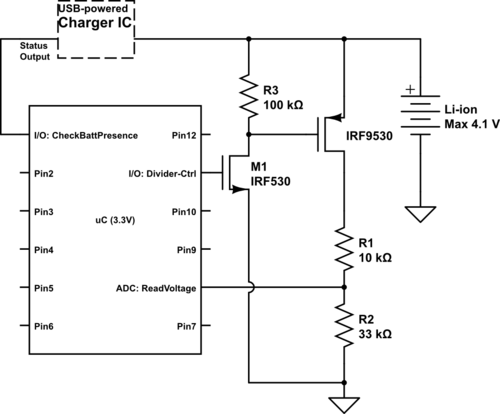

The circuit design for interfacing a DC motor with microcontrollers utilizes the L293D H-bridge, which allows for bidirectional control of the motor. The L293D is a dual H-bridge driver capable of controlling the direction and speed of two DC motors. It operates by receiving control signals from the microcontroller, which can be programmed to vary the duty cycle of the PWM signal. This modulation of the PWM signal effectively adjusts the average voltage supplied to the motor, thereby controlling its speed.

In addition to the L293D, a transistor-based H-bridge can also be employed for applications requiring higher current ratings or more robust control. This configuration typically consists of four transistors arranged in an H-bridge topology, allowing the current to flow in either direction through the motor based on the microcontroller's output signals.

The interfacing process with microcontrollers such as the 8051, AVR, or PIC involves connecting the control pins of the H-bridge to the respective GPIO pins of the microcontroller. The microcontroller is programmed to output PWM signals on these pins, which dictate the motor's speed and rotation direction. The PWM frequency can be adjusted according to the specific application requirements, ensuring smooth operation of the DC motor.

This setup is widely used in robotics and automation projects, where precise control of motor speed and direction is essential. Proper selection of components, including the H-bridge, microcontroller, and additional protective elements like diodes to prevent back EMF, is crucial for the reliability and efficiency of the circuit.DC motor interfacing with microcontroller with the help of L293D H-bridge and trasistor based H-bridge. DC motor speed control using PWM. Interfacing DC motor with 8051, AVR, PIC microcontroller.. 🔗 External reference

The circuit design for interfacing a DC motor with microcontrollers utilizes the L293D H-bridge, which allows for bidirectional control of the motor. The L293D is a dual H-bridge driver capable of controlling the direction and speed of two DC motors. It operates by receiving control signals from the microcontroller, which can be programmed to vary the duty cycle of the PWM signal. This modulation of the PWM signal effectively adjusts the average voltage supplied to the motor, thereby controlling its speed.

In addition to the L293D, a transistor-based H-bridge can also be employed for applications requiring higher current ratings or more robust control. This configuration typically consists of four transistors arranged in an H-bridge topology, allowing the current to flow in either direction through the motor based on the microcontroller's output signals.

The interfacing process with microcontrollers such as the 8051, AVR, or PIC involves connecting the control pins of the H-bridge to the respective GPIO pins of the microcontroller. The microcontroller is programmed to output PWM signals on these pins, which dictate the motor's speed and rotation direction. The PWM frequency can be adjusted according to the specific application requirements, ensuring smooth operation of the DC motor.

This setup is widely used in robotics and automation projects, where precise control of motor speed and direction is essential. Proper selection of components, including the H-bridge, microcontroller, and additional protective elements like diodes to prevent back EMF, is crucial for the reliability and efficiency of the circuit.DC motor interfacing with microcontroller with the help of L293D H-bridge and trasistor based H-bridge. DC motor speed control using PWM. Interfacing DC motor with 8051, AVR, PIC microcontroller.. 🔗 External reference