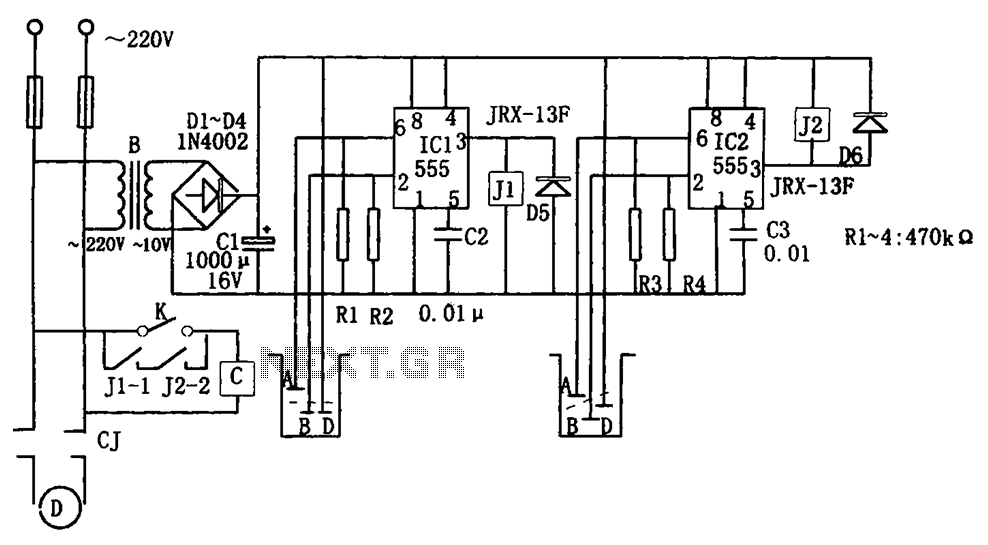

Level 555 a control circuit diagram

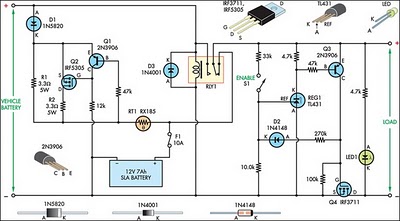

The level control circuit comprises a step-down rectifier circuit, a trigger circuit utilizing two 555 timer ICs (IC1 and IC2), and a relay control circuit. The rectifier circuit is responsible for providing the necessary DC voltage for the flip-flop IC1, which controls the water pump based on the water level in the tower. The triggering circuit IC2 operates in conjunction with high-water level sensors to manage the pumping process. When the water level in the tower reaches probe B or D, which are positioned above the water line, IC1 is grounded, causing IC1 to be set. This results in a high output from IC1, activating relay J1, which closes contact J1-1 and energizes the motor to commence pumping. As the water level rises to probe A, IC1 is reset, producing a low output that releases relay J1, opening contact J1-1 and halting the pump operation, thus achieving automatic control of the water tower. Probes B and D are typically installed at a certain depth below the water surface; under normal conditions, IC2 (555) is set to a height of 2 feet and resets, producing a low output that activates pin J2, closing contact J2-2. If continuous pumping causes the water level at probes B and D to fall, IC2 will detect this drop and trigger a low output, releasing pin J2 and opening contact J2-2 to disconnect power from the motor, preventing idle operation while monitoring the well water level.

The level control circuit is designed to provide an efficient and automated solution for managing water levels in a tower and well system. The step-down rectifier circuit converts AC voltage to a stable DC voltage, ensuring that both timer ICs operate effectively. The 555 timer ICs are configured as flip-flops, which allow for precise control of the water pump based on the input from the water level probes.

In operation, the system continuously monitors the water levels through the probes. When the water level in the tower drops below a predetermined threshold, the circuit activates the pump, ensuring that the water level is maintained. Conversely, when the water level reaches the upper threshold, the circuit deactivates the pump to prevent overflow. The relay control circuit serves as a switching mechanism that connects or disconnects power to the pump based on the outputs from the timer ICs.

The positioning of probes B, D, and A is critical for the accurate functioning of the system. Proper calibration of these probes ensures that the water levels are monitored effectively, allowing for timely activation and deactivation of the pump. Additionally, the use of a relay provides electrical isolation between the control circuit and the high-power motor, enhancing safety and reliability.

Overall, this level control circuit is an effective solution for automated water management, utilizing widely available components to achieve reliable operation in various applications. As shown for the level control circuit. The control circuit consists of step-down rectifier circuit, trigger circuit 555 (IC1, IC2), relay control circuit. Where the buck recti fier circuit of the entire control circuit to provide the DC voltage corresponding to the flip-flop IC1 low water tower water pump control circuit, triggering circuit IC2 corresponding to the high-water wells to pump water for the control circuit.When the water level inside the water tower probe B, D tower above the water line, IC1 pin is ground level, so that IC1 be set, high pin output relay J1 pull, contact J1- 1 is closed, because the motor is energized and pumping operation performed pumping; when the water level rises to probe a, corresponding IC1 is reset, low output enable J1 release, contact J1-1 disconnect power pumps stopped, thus the water tower to achieve automatic control. Well placed in the probe B, D, under normal circumstances, should a certain depth below the water surface, so IC2 (555) by 2 feet high and reset, low output enable pin J2 pull, touch point J2-2 is closed.

When leaving due to continuous pumping B, D EXPLORATION high in the water, IC2 occur due feet set low, high output enable pin J2 release, contact J2-2 disconnect the motor off electricity stopped, thus avoiding motor idling, while the water level of wells for testing.

The level control circuit is designed to provide an efficient and automated solution for managing water levels in a tower and well system. The step-down rectifier circuit converts AC voltage to a stable DC voltage, ensuring that both timer ICs operate effectively. The 555 timer ICs are configured as flip-flops, which allow for precise control of the water pump based on the input from the water level probes.

In operation, the system continuously monitors the water levels through the probes. When the water level in the tower drops below a predetermined threshold, the circuit activates the pump, ensuring that the water level is maintained. Conversely, when the water level reaches the upper threshold, the circuit deactivates the pump to prevent overflow. The relay control circuit serves as a switching mechanism that connects or disconnects power to the pump based on the outputs from the timer ICs.

The positioning of probes B, D, and A is critical for the accurate functioning of the system. Proper calibration of these probes ensures that the water levels are monitored effectively, allowing for timely activation and deactivation of the pump. Additionally, the use of a relay provides electrical isolation between the control circuit and the high-power motor, enhancing safety and reliability.

Overall, this level control circuit is an effective solution for automated water management, utilizing widely available components to achieve reliable operation in various applications. As shown for the level control circuit. The control circuit consists of step-down rectifier circuit, trigger circuit 555 (IC1, IC2), relay control circuit. Where the buck recti fier circuit of the entire control circuit to provide the DC voltage corresponding to the flip-flop IC1 low water tower water pump control circuit, triggering circuit IC2 corresponding to the high-water wells to pump water for the control circuit.When the water level inside the water tower probe B, D tower above the water line, IC1 pin is ground level, so that IC1 be set, high pin output relay J1 pull, contact J1- 1 is closed, because the motor is energized and pumping operation performed pumping; when the water level rises to probe a, corresponding IC1 is reset, low output enable J1 release, contact J1-1 disconnect power pumps stopped, thus the water tower to achieve automatic control. Well placed in the probe B, D, under normal circumstances, should a certain depth below the water surface, so IC2 (555) by 2 feet high and reset, low output enable pin J2 pull, touch point J2-2 is closed.

When leaving due to continuous pumping B, D EXPLORATION high in the water, IC2 occur due feet set low, high output enable pin J2 release, contact J2-2 disconnect the motor off electricity stopped, thus avoiding motor idling, while the water level of wells for testing.