lithium polymer peak charger

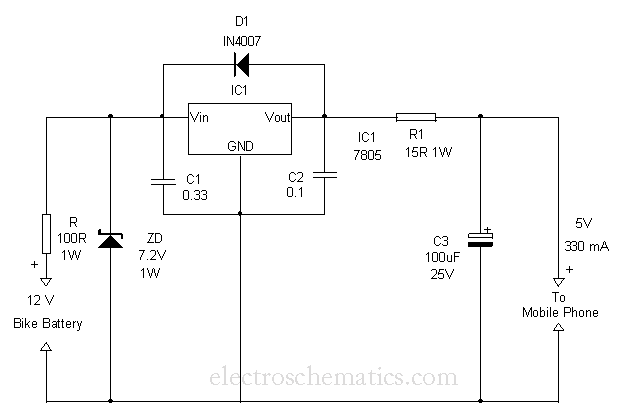

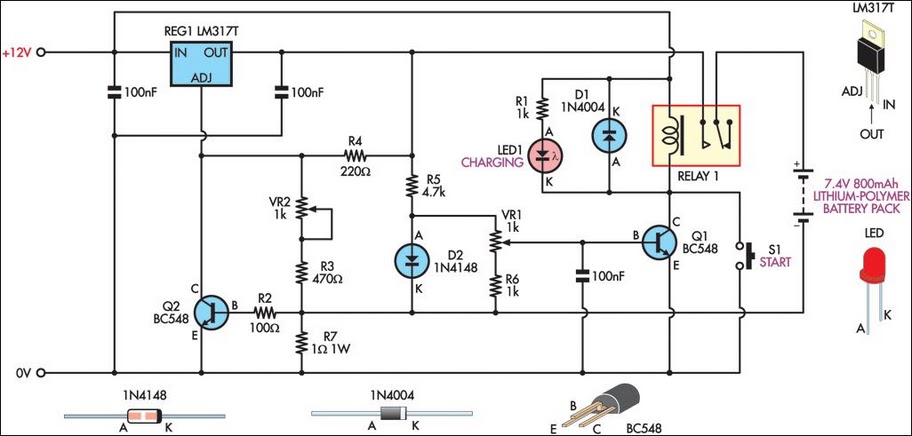

This circuit was designed to charge Lithium-Polymer cells utilized in model aircraft. Lithium-Polymer cells are significantly lighter than Ni-Cad battery packs with equivalent voltage and amp-hour ratings. However, they necessitate a strict charging and discharging protocol to maximize their lifespan.

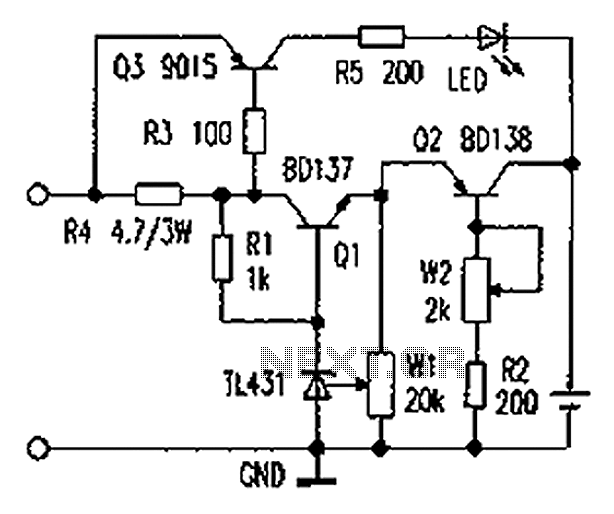

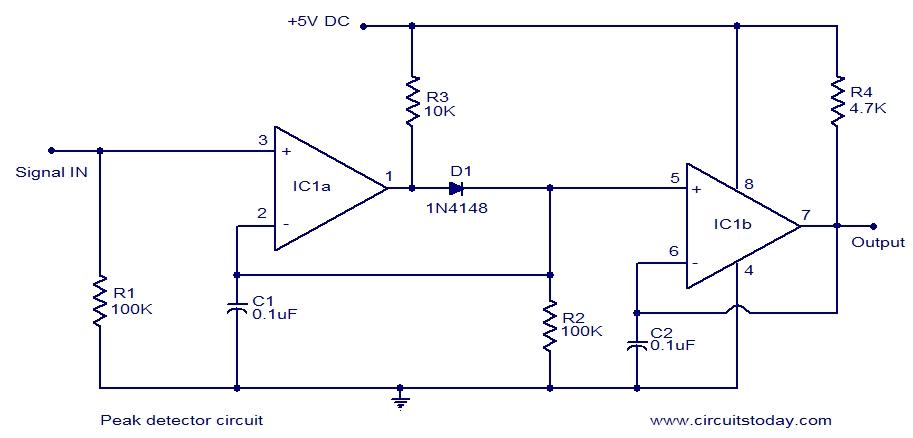

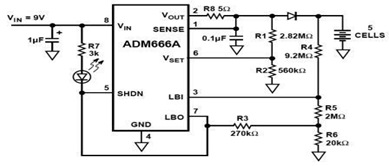

The charging circuit for Lithium-Polymer cells typically incorporates a dedicated charger IC, which is designed to manage the unique requirements of these batteries. A common charging method used is the constant current/constant voltage (CC/CV) approach. Initially, the charger supplies a constant current until the battery voltage reaches a predefined threshold, typically around 4.2 volts per cell. At this point, the charger transitions to constant voltage mode, maintaining the voltage while allowing the current to taper off as the battery approaches full charge.

In addition to the charging IC, the circuit may include a microcontroller for monitoring the charging process and ensuring safety features are in place. This microcontroller can manage temperature sensors to prevent overheating, as Lithium-Polymer cells are sensitive to temperature variations. Furthermore, the circuit design should incorporate a balance charging feature, especially if multiple cells are connected in series. This ensures that each cell receives the appropriate charge, preventing overcharging and extending the overall lifespan of the battery pack.

Protection circuitry is also critical in the design. This can include over-voltage, under-voltage, and over-current protection to safeguard the cells during both charging and discharging. Fuses or resettable polyfuses may be implemented to provide additional safety measures.

Overall, the design of a Lithium-Polymer charging circuit for model aircraft must prioritize weight reduction, efficiency, and safety, ensuring optimal performance while adhering to the strict charging requirements of Lithium-Polymer technology.This circuit was developed to charge the Lithium-Polymer cells used in a model aircraft. Lithium-Polymer cells are incredibly lightweight compared to Ni-cad battery packs of the same voltage and amp-hour rating. Their only drawback is that they require a rigid charge and discharge regime to achieve maximum life..

🔗 External reference

The charging circuit for Lithium-Polymer cells typically incorporates a dedicated charger IC, which is designed to manage the unique requirements of these batteries. A common charging method used is the constant current/constant voltage (CC/CV) approach. Initially, the charger supplies a constant current until the battery voltage reaches a predefined threshold, typically around 4.2 volts per cell. At this point, the charger transitions to constant voltage mode, maintaining the voltage while allowing the current to taper off as the battery approaches full charge.

In addition to the charging IC, the circuit may include a microcontroller for monitoring the charging process and ensuring safety features are in place. This microcontroller can manage temperature sensors to prevent overheating, as Lithium-Polymer cells are sensitive to temperature variations. Furthermore, the circuit design should incorporate a balance charging feature, especially if multiple cells are connected in series. This ensures that each cell receives the appropriate charge, preventing overcharging and extending the overall lifespan of the battery pack.

Protection circuitry is also critical in the design. This can include over-voltage, under-voltage, and over-current protection to safeguard the cells during both charging and discharging. Fuses or resettable polyfuses may be implemented to provide additional safety measures.

Overall, the design of a Lithium-Polymer charging circuit for model aircraft must prioritize weight reduction, efficiency, and safety, ensuring optimal performance while adhering to the strict charging requirements of Lithium-Polymer technology.This circuit was developed to charge the Lithium-Polymer cells used in a model aircraft. Lithium-Polymer cells are incredibly lightweight compared to Ni-cad battery packs of the same voltage and amp-hour rating. Their only drawback is that they require a rigid charge and discharge regime to achieve maximum life..

🔗 External reference