Need Help Deciphering Circuit Board Schematic

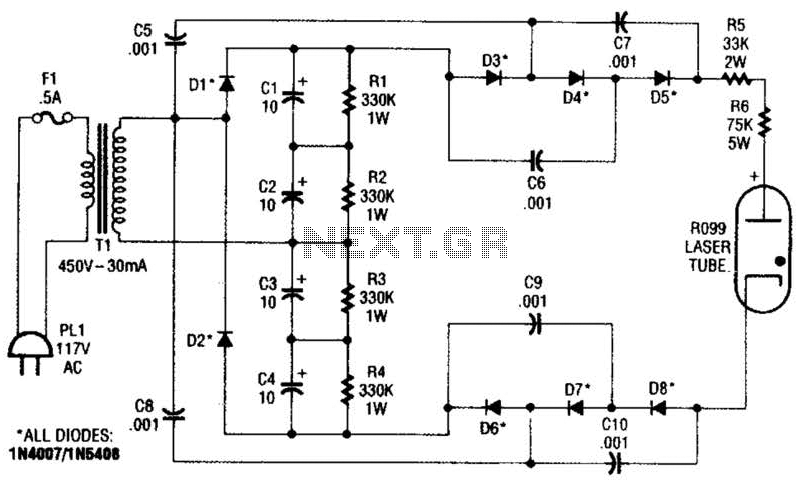

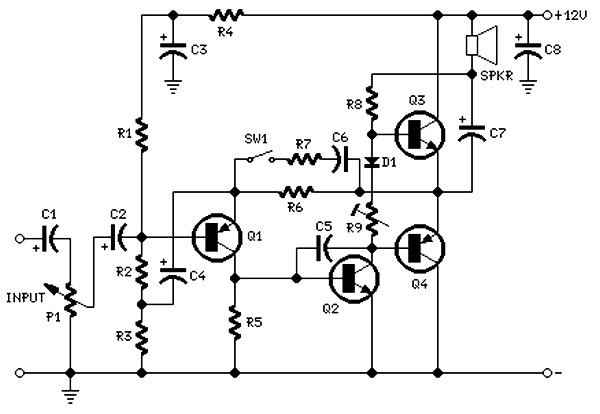

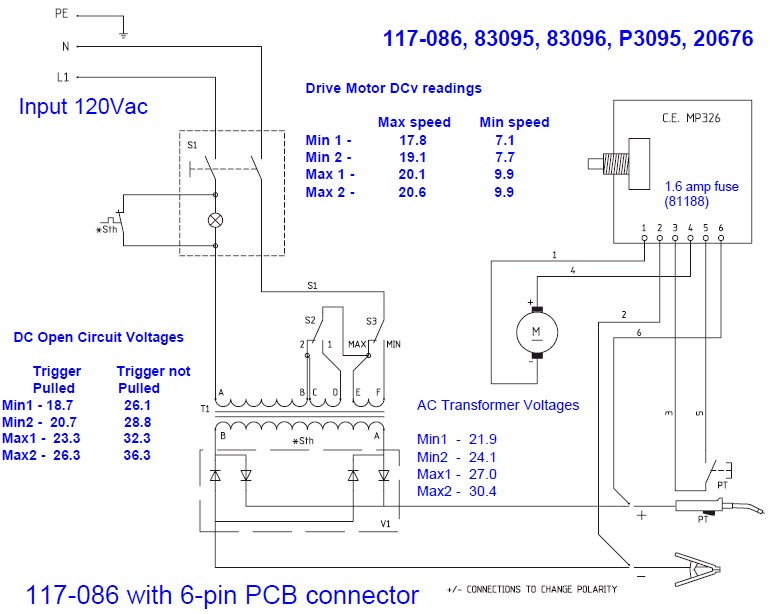

The wire speed DC motor consistently receives approximately 20 volts, irrespective of the switch position on the nozzle handle. The switch has been tested with an ohmmeter and functions properly. Even after disconnecting the switch from the circuit board, the motor continues to operate. A visual inspection of the circuit board has led to the creation of a schematic in EAGLE CAD, which is believed to be 99% accurate. A friend replaced two components: one in a TO-220 package and the other in a TO-92 package. Currently, the original components are not available for identification. The existing components include an LM7812C voltage regulator (in the TO-220 package) and an MPF 102 601 N-channel RF amplifier (in the TO-92 package). In the schematic, both components have been replaced with standard NPN transistors, though the appropriateness of this substitution is uncertain. The circuit also contains two "black and silver" diodes and two "black and orange" diodes, labeled accordingly on the schematic. Assistance is sought in interpreting this schematic, as it is confusing. The welder operates on DC only; thus, the line voltage enters the welder, passes through a power switch, a transformer, and power diodes. The wire speed control circuit board is connected to this rectified power. The presence of a rectifier on the circuit board raises questions. Additionally, there are diodes at the bottom of the schematic oriented to allow current flow from negative to positive but not the reverse, unless they are Zener diodes. A PDF schematic and a "semi-schematic" from the manufacturer have been included, as the file size is limited. Clarification is needed on how the system functions. The voltage entering the board ranges from approximately 18.7 to 36.3 volts, while the voltage supplied to the DC motor ranges from about 7.1 to 20.6 volts. The LM7812C has been replaced with a suitable TO-220 NPN transistor (MJE3055T, part number 276-2020 from RadioShack, also referred to as TIP3055), restoring proper functionality to the trigger. The MPF 102 has been substituted with a proper TO-92 NPN transistor (MPS2222A, part number 276-2009 from RadioShack). The base and collector have been switched as suggested by Resqueline, resulting in the wire feed speed functioning correctly. Further testing will determine the wire feed speed in inches per minute.

The circuit under discussion operates as a wire speed control system for a DC motor, typically used in welding applications. The main power source provides a voltage range of approximately 18.7 to 36.3 volts, which is regulated and conditioned before being delivered to the motor. The LM7812C voltage regulator was originally employed to provide a stable 12V output; however, it has been replaced with an MJE3055T NPN transistor to facilitate higher current handling capabilities required by the motor. This substitution is critical given the motor's power demands and ensures that the control circuit can manage the motor's operation effectively.

The circuit board's design includes a rectifier stage, which is unusual in a DC-only welder setup. This rectifier is likely implemented to ensure that any fluctuations in the input voltage are smoothed out, providing a consistent DC output to the motor. The presence of diodes, particularly those oriented to allow current flow in one direction, serves to protect the circuit from potential back EMF generated by the motor when it is turned off or when the load changes suddenly.

The diodes labeled as "black and silver" and "black and orange" are likely standard rectifier diodes, while the orientation of the other diodes must be confirmed to determine their function in the circuit. If they are Zener diodes, they may be used for voltage regulation or protection against overvoltage conditions.

The modifications made to the circuit, including the replacement of the MPF 102 with an MPS2222A transistor and the adjustment of the base and collector connections, indicate an effort to optimize the control signal to the motor. This change has reportedly improved the wire feed speed functionality, suggesting that the previous configuration may have been limiting the circuit's performance.

In summary, the circuit's design integrates various components to manage the operation of a wire speed DC motor effectively. The adjustments made to replace components and the inquiry into the schematic's functionality reflect a thorough approach to troubleshooting and optimizing the circuit for its intended application. Further testing will provide insights into the performance metrics, such as wire feed speed in inches per minute, which are critical for evaluating the system's overall efficacy.The wire speed DC motor is constantly receiving about 20 volts, regardless of the state of the switch on the nozzle handle. I checked the switch with an ohm meter. The switch works fine. I even disconnected the switch from the circuit board. The motor is still going. By looking at the physical circuit board, I have come up with the following schematic in EAGLE CAD, which I believe to be 99% accurate.

My friend replaced two components, one was in a TO-220 package, and the other was in a TO-92 package. At this time, he is unable to find the components he removed from the board, so it is anybody`s guess as to what they were.

The components that are in the circuit now are an LM7812C voltage regulator (the TO-220 package) and an MPF 102 601 N-channel RF amplifier (the TO-92 package). (In the schematic, I replaced both with standard NPN transistors. I have no idea if that makes any sense. ). There are also two "black and silver" diodes on the board, and two "black and orange" diodes on the board.

They are labeled as such on the schematic. That is the reason I`m posting. I need help deciphering this schematic, because it doesn`t make any sense to me. For instance, the welder is DC only, no AC side. So the line voltage comes into the welder, goes to the power switch, through a transformer, and then through the power diodes. The wire speed control circuit board is then connected here, to this rectified power. So why is there a rectifier on the circuit board Also, there are diodes towards the bottom of the schematic, which point up (i.

e. , allow flow from neg -> pos, but not pos -> neg (unless they`re Zener diodes. I`m not sure). I have included the schematic I made in PDF form, as well as a "semi-schematic" that I received from the manufacturer, as that is about all I can fit into 97KB. I need help to make sense as to how this thing is supposed to work. The voltage coming into the board is approximately 18. 7 - 36. 3 volts, and the voltage going to the DC motor is approximately 7. 1 - 20. 6 volts. I replaced the LM7812C with a proper TO-220 NPN transistor (MJE3055T, part number 276-2020 from RadioShack (they call it a TIP3055).

The trigger now works as it`s supposed to. I replaced the MPF 102 with a proper TO-92 NPN transistor (MPS2222A, part number 276-2009 from RadioShack). I also switched the base and the collector around, as suggested by Resqueline. The wire feed speed now appears to work correctly. I`ll have to run some wire and test what the wire feed speed is in inches per minute. 🔗 External reference

The circuit under discussion operates as a wire speed control system for a DC motor, typically used in welding applications. The main power source provides a voltage range of approximately 18.7 to 36.3 volts, which is regulated and conditioned before being delivered to the motor. The LM7812C voltage regulator was originally employed to provide a stable 12V output; however, it has been replaced with an MJE3055T NPN transistor to facilitate higher current handling capabilities required by the motor. This substitution is critical given the motor's power demands and ensures that the control circuit can manage the motor's operation effectively.

The circuit board's design includes a rectifier stage, which is unusual in a DC-only welder setup. This rectifier is likely implemented to ensure that any fluctuations in the input voltage are smoothed out, providing a consistent DC output to the motor. The presence of diodes, particularly those oriented to allow current flow in one direction, serves to protect the circuit from potential back EMF generated by the motor when it is turned off or when the load changes suddenly.

The diodes labeled as "black and silver" and "black and orange" are likely standard rectifier diodes, while the orientation of the other diodes must be confirmed to determine their function in the circuit. If they are Zener diodes, they may be used for voltage regulation or protection against overvoltage conditions.

The modifications made to the circuit, including the replacement of the MPF 102 with an MPS2222A transistor and the adjustment of the base and collector connections, indicate an effort to optimize the control signal to the motor. This change has reportedly improved the wire feed speed functionality, suggesting that the previous configuration may have been limiting the circuit's performance.

In summary, the circuit's design integrates various components to manage the operation of a wire speed DC motor effectively. The adjustments made to replace components and the inquiry into the schematic's functionality reflect a thorough approach to troubleshooting and optimizing the circuit for its intended application. Further testing will provide insights into the performance metrics, such as wire feed speed in inches per minute, which are critical for evaluating the system's overall efficacy.The wire speed DC motor is constantly receiving about 20 volts, regardless of the state of the switch on the nozzle handle. I checked the switch with an ohm meter. The switch works fine. I even disconnected the switch from the circuit board. The motor is still going. By looking at the physical circuit board, I have come up with the following schematic in EAGLE CAD, which I believe to be 99% accurate.

My friend replaced two components, one was in a TO-220 package, and the other was in a TO-92 package. At this time, he is unable to find the components he removed from the board, so it is anybody`s guess as to what they were.

The components that are in the circuit now are an LM7812C voltage regulator (the TO-220 package) and an MPF 102 601 N-channel RF amplifier (the TO-92 package). (In the schematic, I replaced both with standard NPN transistors. I have no idea if that makes any sense. ). There are also two "black and silver" diodes on the board, and two "black and orange" diodes on the board.

They are labeled as such on the schematic. That is the reason I`m posting. I need help deciphering this schematic, because it doesn`t make any sense to me. For instance, the welder is DC only, no AC side. So the line voltage comes into the welder, goes to the power switch, through a transformer, and then through the power diodes. The wire speed control circuit board is then connected here, to this rectified power. So why is there a rectifier on the circuit board Also, there are diodes towards the bottom of the schematic, which point up (i.

e. , allow flow from neg -> pos, but not pos -> neg (unless they`re Zener diodes. I`m not sure). I have included the schematic I made in PDF form, as well as a "semi-schematic" that I received from the manufacturer, as that is about all I can fit into 97KB. I need help to make sense as to how this thing is supposed to work. The voltage coming into the board is approximately 18. 7 - 36. 3 volts, and the voltage going to the DC motor is approximately 7. 1 - 20. 6 volts. I replaced the LM7812C with a proper TO-220 NPN transistor (MJE3055T, part number 276-2020 from RadioShack (they call it a TIP3055).

The trigger now works as it`s supposed to. I replaced the MPF 102 with a proper TO-92 NPN transistor (MPS2222A, part number 276-2009 from RadioShack). I also switched the base and the collector around, as suggested by Resqueline. The wire feed speed now appears to work correctly. I`ll have to run some wire and test what the wire feed speed is in inches per minute. 🔗 External reference