On-Off Temperature Control

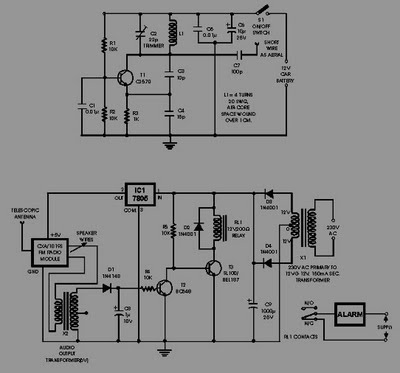

This circuit controls a load, specifically a DC brushless fan, based on temperature compared to a setpoint. The transducer used is a diode operating in the forward polarization regime. When forward-biased, the forward voltage drop across the diode exhibits a temperature dependence, characterized by a negative linear slope. This phenomenon occurs due to the Boltzmann distribution, which allows electrons to transition to the conduction band thermally, resulting in a decrease in the voltage drop across the diode. The comparator utilized is an LM158/258/358, functioning in open-loop mode. The inverting input is connected to the diode sensor, while the non-inverting input is connected to a reference voltage. As the temperature exceeds the setpoint, the forward voltage drops below the reference voltage, causing the comparator output to activate the transistor and subsequently the fan. The setpoint can be adjusted using a potentiometer, and an LM3914 LED driver can be employed to create a temperature setpoint indicator, which requires careful calibration and the use of Excel to calculate the slope and intercept. The comparator is capable of distinguishing differences as small as 10 µV, translating to approximately 0.01 °C differences. With precise adjustment of the potentiometer, the circuit can detect body heat from a distance of 0.5 cm from the sensor or ambient heat, leading to continuous activation and deactivation of the fan. Potential applications include heatsink cooling, computer emergency cooling (although a linear device may be preferable to an on-off control), and metal cooling during drilling.

The circuit operates by leveraging the temperature-sensitive characteristics of the diode, which serves as a reliable sensor for monitoring temperature changes. The LM158/258/358 comparator is chosen for its capability to operate in open-loop configurations, allowing for straightforward integration of the diode's voltage drop into the control logic. The reference voltage is typically set using a voltage divider network, which can be finely tuned using a potentiometer to establish the desired temperature threshold.

In practical applications, the circuit can be implemented in environments where temperature regulation is critical. For instance, in electronic devices that generate significant heat, such as computers, the circuit can automatically activate cooling fans to prevent overheating. The use of the LM3914 LED driver for visual feedback on the setpoint enhances user interaction, providing a clear indication of the current temperature status relative to the established threshold.

The design's sensitivity to small voltage changes allows for precise temperature control, making it suitable for delicate applications where maintaining specific temperature ranges is essential. Additionally, the ability to detect minor temperature variations enables the circuit to respond quickly to changes in ambient conditions, ensuring effective cooling when required. Overall, this circuit design exemplifies a practical and efficient approach to temperature-based load control in various electronic and mechanical applications.This circuit controls a load (in this case a dc brushless fan) based on a temperature compared with a setpoint. THe transduced is a diode in the forward polarization regime. In fact when forward biased, the forward voltage drop accross a diode has a temperature dependance, in particular has a negative linear(ish) slope.

This because of the boltzma nn distribuition, causing electrons to pass to the conduction band thermically, lowering the voltage drop accross the diode. The comparator is simply a LM158/258/358 working in open-loop mode, the inverting input is connected to the diode sensor, and the noninverting to the reference voltage.

Se when the temperature rises above the setpoint, the forward voltage drops under the voltage reference and the comparator output is vccturning on the transistor and so the fan. The setpoint is adjusted with the potentiometer, and you can use a LM3914 led driver to make a temperature setpoint indicator (needs careful calibrations and the use of excel to calculate slope and intercept).

THe comparator can distinguish 10uV differences so approx 0. 01G‚ °C differences (carefully adjusting the potentiometer can allow to feel body heat from 1/2 cm from the sensor, or feel ambient heat, making to turn the fan on and off continuosly) Possible uses Heatsink cooling, computer emergency cooling (but i thint that a linear device would be better than a on-off) metal cooling when drilling etc. 🔗 External reference

The circuit operates by leveraging the temperature-sensitive characteristics of the diode, which serves as a reliable sensor for monitoring temperature changes. The LM158/258/358 comparator is chosen for its capability to operate in open-loop configurations, allowing for straightforward integration of the diode's voltage drop into the control logic. The reference voltage is typically set using a voltage divider network, which can be finely tuned using a potentiometer to establish the desired temperature threshold.

In practical applications, the circuit can be implemented in environments where temperature regulation is critical. For instance, in electronic devices that generate significant heat, such as computers, the circuit can automatically activate cooling fans to prevent overheating. The use of the LM3914 LED driver for visual feedback on the setpoint enhances user interaction, providing a clear indication of the current temperature status relative to the established threshold.

The design's sensitivity to small voltage changes allows for precise temperature control, making it suitable for delicate applications where maintaining specific temperature ranges is essential. Additionally, the ability to detect minor temperature variations enables the circuit to respond quickly to changes in ambient conditions, ensuring effective cooling when required. Overall, this circuit design exemplifies a practical and efficient approach to temperature-based load control in various electronic and mechanical applications.This circuit controls a load (in this case a dc brushless fan) based on a temperature compared with a setpoint. THe transduced is a diode in the forward polarization regime. In fact when forward biased, the forward voltage drop accross a diode has a temperature dependance, in particular has a negative linear(ish) slope.

This because of the boltzma nn distribuition, causing electrons to pass to the conduction band thermically, lowering the voltage drop accross the diode. The comparator is simply a LM158/258/358 working in open-loop mode, the inverting input is connected to the diode sensor, and the noninverting to the reference voltage.

Se when the temperature rises above the setpoint, the forward voltage drops under the voltage reference and the comparator output is vccturning on the transistor and so the fan. The setpoint is adjusted with the potentiometer, and you can use a LM3914 led driver to make a temperature setpoint indicator (needs careful calibrations and the use of excel to calculate slope and intercept).

THe comparator can distinguish 10uV differences so approx 0. 01G‚ °C differences (carefully adjusting the potentiometer can allow to feel body heat from 1/2 cm from the sensor, or feel ambient heat, making to turn the fan on and off continuosly) Possible uses Heatsink cooling, computer emergency cooling (but i thint that a linear device would be better than a on-off) metal cooling when drilling etc. 🔗 External reference