SPEED CONTROLLER CIRCUIT FOR AC MOTOR

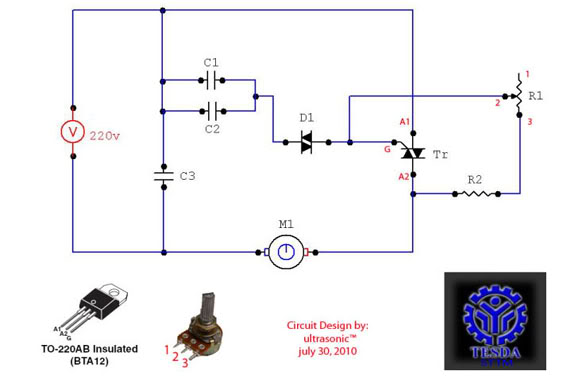

This circuit functions as a motor controller, allowing for easy control and variation of the RPM and phase of an AC motor. The power source is directly 220VAC, and it can handle a load of approximately 1 horsepower AC motor (600W-1kW).

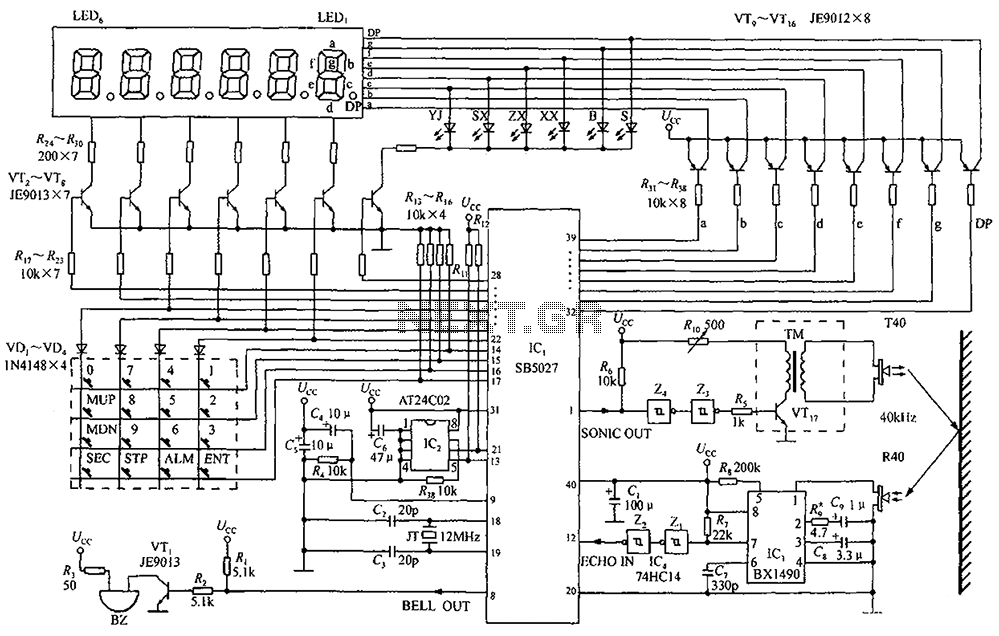

The motor controller circuit is designed to regulate the speed and phase of an AC motor, which is essential for applications requiring precise motor control. The circuit typically includes key components such as capacitors, resistors, and a triac or thyristor for phase control, enabling the adjustment of the motor's speed by altering the voltage and current characteristics.

A common configuration for such a motor controller might include a phase control circuit that utilizes a triac, which allows for the control of the AC waveform delivered to the motor. By adjusting the firing angle of the triac, the effective voltage and current supplied to the motor can be modified, thus controlling the speed. The circuit may also include a microcontroller or a potentiometer for user input, allowing for real-time adjustments to the desired RPM.

Safety features are critical in such designs. A fuse or circuit breaker may be included to protect against overload conditions, while proper heat dissipation measures, such as heat sinks for the triac, ensure reliable operation without overheating. Additionally, snubber circuits may be employed to protect the triac from voltage spikes caused by inductive loads.

The design should also consider the type of AC motor being controlled; for instance, single-phase motors may require different control strategies compared to three-phase motors. Proper filtering and decoupling capacitors can be included to minimize electrical noise and ensure stable operation of the control circuit.

In summary, this motor controller circuit offers a robust solution for varying the RPM and phase control of AC motors, making it suitable for a wide range of industrial and consumer applications.this circuit serves as a motor controller circuit to easily controlling or varying the RPM & Phase control of a AC motor. source: directly 220VAC Load: approx. 1hp AC motor (600w-1kw) CIRCUIT DIAGRAM: COMPONENT PARTLIST: C1 = 2G .. 🔗 External reference

The motor controller circuit is designed to regulate the speed and phase of an AC motor, which is essential for applications requiring precise motor control. The circuit typically includes key components such as capacitors, resistors, and a triac or thyristor for phase control, enabling the adjustment of the motor's speed by altering the voltage and current characteristics.

A common configuration for such a motor controller might include a phase control circuit that utilizes a triac, which allows for the control of the AC waveform delivered to the motor. By adjusting the firing angle of the triac, the effective voltage and current supplied to the motor can be modified, thus controlling the speed. The circuit may also include a microcontroller or a potentiometer for user input, allowing for real-time adjustments to the desired RPM.

Safety features are critical in such designs. A fuse or circuit breaker may be included to protect against overload conditions, while proper heat dissipation measures, such as heat sinks for the triac, ensure reliable operation without overheating. Additionally, snubber circuits may be employed to protect the triac from voltage spikes caused by inductive loads.

The design should also consider the type of AC motor being controlled; for instance, single-phase motors may require different control strategies compared to three-phase motors. Proper filtering and decoupling capacitors can be included to minimize electrical noise and ensure stable operation of the control circuit.

In summary, this motor controller circuit offers a robust solution for varying the RPM and phase control of AC motors, making it suitable for a wide range of industrial and consumer applications.this circuit serves as a motor controller circuit to easily controlling or varying the RPM & Phase control of a AC motor. source: directly 220VAC Load: approx. 1hp AC motor (600w-1kw) CIRCUIT DIAGRAM: COMPONENT PARTLIST: C1 = 2G .. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713