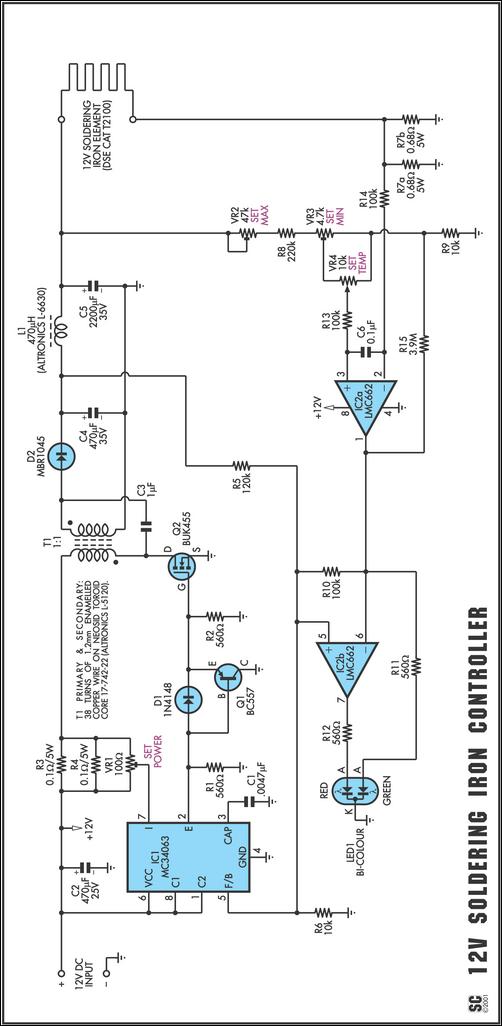

Temperature-Controlled Soldering Iron circuit

One reason commercial soldering stations are costly is that they typically require soldering irons with built-in temperature sensors, such as thermocouples. This circuit removes the necessity for a specialized sensor by detecting the temperature of a soldering iron heating element directly from its resistance. Therefore, this circuit will, in principle, function with any iron whose resistance varies predictably and appropriately with temperature (i.e., has a positive temperature coefficient).

The described circuit operates on the principle of measuring the resistance of the soldering iron heating element to determine its temperature. A positive temperature coefficient (PTC) material is essential for this application, as its resistance increases with temperature. The circuit consists of a microcontroller, a reference resistor, and an analog-to-digital converter (ADC) to facilitate the temperature reading.

In operation, the soldering iron is connected in series with a reference resistor. As the iron heats up, its resistance increases, resulting in a measurable voltage drop across the reference resistor. The microcontroller reads this voltage and, using a pre-calibrated lookup table or a mathematical model, converts the voltage reading into a temperature value.

To ensure accuracy, the circuit may include temperature compensation features and protection mechanisms against overheating. For example, a feedback loop can be integrated, where the microcontroller adjusts the power supplied to the heating element based on the measured temperature, maintaining it within a specified range. Additionally, a display interface can be added to provide real-time temperature readings to the user.

This approach not only simplifies the design by eliminating the need for specialized temperature sensors but also allows for greater flexibility, as it can be adapted to various soldering irons with different resistance characteristics. Overall, this circuit design presents a cost-effective solution for precise temperature control in soldering applications.One reason why commercial soldering stations are expensive is that, in general, they require the use of soldering irons with inbuilt temperature sensors, such as thermocouples. This circuit eliminates the need for a special sensor because it senses the temperature of a soldering iron heating element directly from its resistance.

Thus this circuit will, in principle, work with any iron with a resistance which varies predictably and in the right direction with temperature (ie, positive temperature coefficient).. 🔗 External reference

The described circuit operates on the principle of measuring the resistance of the soldering iron heating element to determine its temperature. A positive temperature coefficient (PTC) material is essential for this application, as its resistance increases with temperature. The circuit consists of a microcontroller, a reference resistor, and an analog-to-digital converter (ADC) to facilitate the temperature reading.

In operation, the soldering iron is connected in series with a reference resistor. As the iron heats up, its resistance increases, resulting in a measurable voltage drop across the reference resistor. The microcontroller reads this voltage and, using a pre-calibrated lookup table or a mathematical model, converts the voltage reading into a temperature value.

To ensure accuracy, the circuit may include temperature compensation features and protection mechanisms against overheating. For example, a feedback loop can be integrated, where the microcontroller adjusts the power supplied to the heating element based on the measured temperature, maintaining it within a specified range. Additionally, a display interface can be added to provide real-time temperature readings to the user.

This approach not only simplifies the design by eliminating the need for specialized temperature sensors but also allows for greater flexibility, as it can be adapted to various soldering irons with different resistance characteristics. Overall, this circuit design presents a cost-effective solution for precise temperature control in soldering applications.One reason why commercial soldering stations are expensive is that, in general, they require the use of soldering irons with inbuilt temperature sensors, such as thermocouples. This circuit eliminates the need for a special sensor because it senses the temperature of a soldering iron heating element directly from its resistance.

Thus this circuit will, in principle, work with any iron with a resistance which varies predictably and in the right direction with temperature (ie, positive temperature coefficient).. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713