tesla circuit

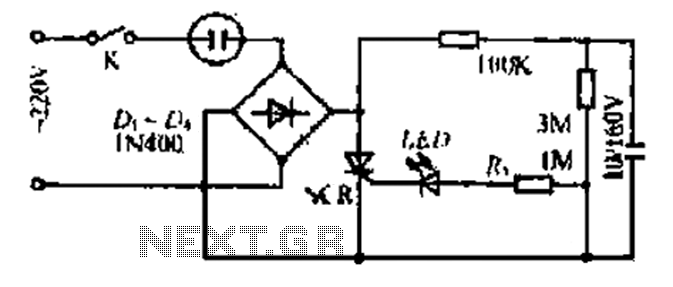

The American Electrician describes a glass battery jar measuring six inches by eight inches, wound with 60 to 80 turns of American wire gauge No. 18 B & S magnet wire. Inside this jar is a primary winding consisting of eight to ten turns of AWG No. 6 B & S wire, with the entire assembly immersed in a vessel containing linseed or mineral oil. Following initial voltage and frequency research by William Crookes, Nikola Tesla developed a series of coils that produced high-voltage, high-frequency currents. In most of Tesla's experiments, he utilized machinery of his own design to create the Tesla effect. These early coils operated using the "disruptive" action of a spark gap. The setup can be replicated using a Ruhmkorff coil, two capacitors, and a specially constructed disruptive coil. The Ruhmkorff coil, connected to a main power source, is wired to capacitors in series at both ends. A spark gap is placed in parallel to the Ruhmkorff coil before the capacitors. The discharge tips are typically metal balls under one inch in diameter, although Tesla experimented with various discharge forms. The capacitors are specially designed, small, and feature high insulation, consisting of movable plates immersed in oil. Smaller plates result in more frequent discharges from this early coil apparatus. These plates also help mitigate the high self-inductance of the secondary coil by adding capacitance. Mica plates are placed in the spark gap to create an air current jet that rises through the gap, assisting in extinguishing the arc and making the discharge more abrupt. An air blast is also employed for this purpose. The capacitors are connected to a double primary, with each coil in series with a capacitor. These form part of the second specially constructed disruptive coil. Each primary has twenty turns of No. 16 B & S rubber-covered wire and is wound separately on rubber tubes at least 1/8th inch thick. The secondary consists of 300 turns of No. 30 B & S silk-covered magnet wire, wound on a rubber tube or rod, with the ends encased in glass or rubber tubes. The primaries must be sufficiently large to allow the secondary coil to fit loosely between them, covering approximately two inches of the secondary. A hard rubber divider is placed between the primary coils. The ends of the primaries that are not connected to the capacitors lead to a spark gap. Tesla's later coils were significantly larger and operated at much higher power levels. These later systems were powered by large high-voltage transformers, utilized banks of glass bottle capacitors immersed in oil to minimize corona losses, and employed rotating spark gaps to manage increased power levels. Tesla also eliminated the use of oil for insulating transformer coils, opting instead for the insulating properties of air. Tesla coils achieve significant voltage gain by loosely coupling two resonant LC circuits, using an air-core (ironless) transformer. Unlike conventional transformers, whose gain is restricted by the ratio of turns in the windings, Tesla coils' voltage gain is proportional to the square root of the ratio of secondary to primary inductances. In a later patent (U.S. Patent 1,119,732, "Apparatus for Transmitting Electrical Energy"), Tesla referred to this device as a high-voltage, air-core, self-regenerative resonant transformer capable of generating very high voltages at high frequencies. This terminology is less common in contemporary use. The later coil type is now the standard device constructed by modern enthusiasts, functioning as an air-core, dual-tuned resonant transformer that generates very high voltages at radio frequencies (RF). The coil achieves substantial voltage gain by transferring energy from one resonant circuit (the primary) to another (the secondary).

The described apparatus is fundamentally a high-voltage transformer system designed for generating and manipulating electrical energy at high frequencies. The primary and secondary coils are engineered to resonate at specific frequencies, allowing for efficient energy transfer. The construction materials, such as rubber for insulation and mica for the spark gap, are chosen for their electrical properties, ensuring safety and performance. The use of oil in the capacitors serves to enhance dielectric strength, thereby supporting higher voltage operations while reducing the risk of electrical breakdown. The overall design reflects advanced principles of electromagnetic theory, particularly in the context of resonant circuits, where the interplay between inductance and capacitance is exploited to achieve voltage amplification. This setup not only demonstrates Tesla's innovative approach to electrical engineering but also serves as a foundational concept for modern high-voltage applications in various fields, including telecommunications and power transmission.The American Electrician gives a description of one wherein a glass battery jar, six inches by eight inches, is wound with 60 to 80 turns of American wire gauge No. 18 B & S magnet wire. Into this is slipped a primary consisting of eight to ten turns of AWG No. 6 B & S wire, and the whole combination immersed in a vessel containing linseed or mine ral oil. (Norrie, pg. 34-35) Following the initial research of voltage and frequency by William Crookes, Tesla developed a series of coils that produced high-voltage, high-frequency currents. In the majority of Tesla`s experiments, he used machinery of his own design to produce the Tesla effect.

These early coils would use the "disruptive" action of a spark gap in their operation. The setup can be duplicated by a Ruhmkorff coil, two condensers (now called capacitors), and a second, specially constructed, disruptive coil. (Norrie, pg. 228) The Ruhmkorff coil, being fed from a main source, is wired to capacitors on both ends in series.

A spark gap is placed in parallel to the Ruhmkorff coil before the capacitors. The discharge tips were usually metal balls under one inch in diameter, though Tesla used various forms of dischargers. The capacitors were of a special design, small with high insulation. These capacitors consisted of plates in oil that were movable. The smaller the plates, the more frequent the discharge of this early coil apparatus. The plates also help nullify the high self inductance of the secondary coil by adding capacity to it.

Mica plates were placed in the spark gap to establish an air current jet to go up through the gap. This helped to extinguish the arc, making the discharge more abrupt. An air blast was also used for this objective. (Norrie, pg. 230-231) The capacitors are connected to a double primary (each coil in series with a capacitor). These are part of the second specially constructed disruptive coil. The primaries each have twenty turns of No. 16 B & S rubber covered wire and are wound separately on rubber tubes not less than a 1/8th inch thick. The secondary has 300 turns of No. 30 B & S silk-covered magnet wire, wound on rubber tube or rod, and the ends encased in glass or rubber tubes.

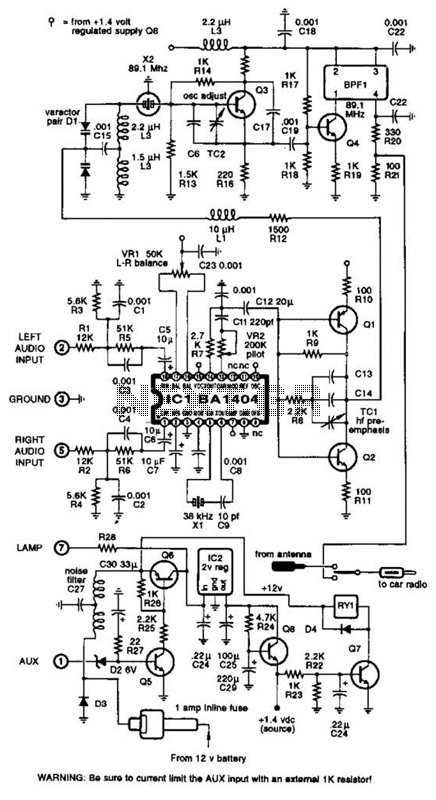

The primaries must be large enough to be loose when the secondary coil is place between the coils. The primaries must cover around two inches of the secondary. A hard rubber division must be placed between these primary coils. The ends of the primaries not connected with the capacitors are lead to a spark gap. (Norrie, pg. 35-36) Tesla`s later coils were considerably larger and operated at much higher power levels. These later systems were powered from large high voltage power transformers, used banks of glass bottle capacitors immersed in oil to reduce corona losses, and used rotating spark gaps to handle the higher power levels. Tesla also dispensed with using oil to insulate the transformer coils, relying instead on the insulating properties of air.

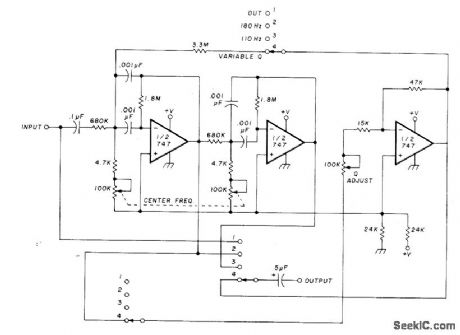

Tesla coils achieve great gain in voltage by loosely coupling two resonant LC circuits together, using an air-core (ironless) transformer. Unlike a conventional transformer, whose gain is limited to the ratio of the numbers of turns in the windings, Tesla coils` voltage gain is proportional to the square root of the ratio of secondary and primary inductances.

When Tesla patented a later device (U. S. Patent 1, 119, 732 ” Apparatus for Transmitting Electrical Energy), he called it a high-voltage, air-core, self-regenerative resonant transformer that generates very high voltages at high frequency. However, this phrase is no longer in conventional use. This later coil type is the usual device built by modern enthusiasts. It is an air-core, dual-tuned resonant transformer that generates very high voltages at radio frequencies (RF).

The coil achieves a great gain in voltage by transferring energy from one resonant circuit (the primary) to the other (the secondary) o 🔗 External reference

The described apparatus is fundamentally a high-voltage transformer system designed for generating and manipulating electrical energy at high frequencies. The primary and secondary coils are engineered to resonate at specific frequencies, allowing for efficient energy transfer. The construction materials, such as rubber for insulation and mica for the spark gap, are chosen for their electrical properties, ensuring safety and performance. The use of oil in the capacitors serves to enhance dielectric strength, thereby supporting higher voltage operations while reducing the risk of electrical breakdown. The overall design reflects advanced principles of electromagnetic theory, particularly in the context of resonant circuits, where the interplay between inductance and capacitance is exploited to achieve voltage amplification. This setup not only demonstrates Tesla's innovative approach to electrical engineering but also serves as a foundational concept for modern high-voltage applications in various fields, including telecommunications and power transmission.The American Electrician gives a description of one wherein a glass battery jar, six inches by eight inches, is wound with 60 to 80 turns of American wire gauge No. 18 B & S magnet wire. Into this is slipped a primary consisting of eight to ten turns of AWG No. 6 B & S wire, and the whole combination immersed in a vessel containing linseed or mine ral oil. (Norrie, pg. 34-35) Following the initial research of voltage and frequency by William Crookes, Tesla developed a series of coils that produced high-voltage, high-frequency currents. In the majority of Tesla`s experiments, he used machinery of his own design to produce the Tesla effect.

These early coils would use the "disruptive" action of a spark gap in their operation. The setup can be duplicated by a Ruhmkorff coil, two condensers (now called capacitors), and a second, specially constructed, disruptive coil. (Norrie, pg. 228) The Ruhmkorff coil, being fed from a main source, is wired to capacitors on both ends in series.

A spark gap is placed in parallel to the Ruhmkorff coil before the capacitors. The discharge tips were usually metal balls under one inch in diameter, though Tesla used various forms of dischargers. The capacitors were of a special design, small with high insulation. These capacitors consisted of plates in oil that were movable. The smaller the plates, the more frequent the discharge of this early coil apparatus. The plates also help nullify the high self inductance of the secondary coil by adding capacity to it.

Mica plates were placed in the spark gap to establish an air current jet to go up through the gap. This helped to extinguish the arc, making the discharge more abrupt. An air blast was also used for this objective. (Norrie, pg. 230-231) The capacitors are connected to a double primary (each coil in series with a capacitor). These are part of the second specially constructed disruptive coil. The primaries each have twenty turns of No. 16 B & S rubber covered wire and are wound separately on rubber tubes not less than a 1/8th inch thick. The secondary has 300 turns of No. 30 B & S silk-covered magnet wire, wound on rubber tube or rod, and the ends encased in glass or rubber tubes.

The primaries must be large enough to be loose when the secondary coil is place between the coils. The primaries must cover around two inches of the secondary. A hard rubber division must be placed between these primary coils. The ends of the primaries not connected with the capacitors are lead to a spark gap. (Norrie, pg. 35-36) Tesla`s later coils were considerably larger and operated at much higher power levels. These later systems were powered from large high voltage power transformers, used banks of glass bottle capacitors immersed in oil to reduce corona losses, and used rotating spark gaps to handle the higher power levels. Tesla also dispensed with using oil to insulate the transformer coils, relying instead on the insulating properties of air.

Tesla coils achieve great gain in voltage by loosely coupling two resonant LC circuits together, using an air-core (ironless) transformer. Unlike a conventional transformer, whose gain is limited to the ratio of the numbers of turns in the windings, Tesla coils` voltage gain is proportional to the square root of the ratio of secondary and primary inductances.

When Tesla patented a later device (U. S. Patent 1, 119, 732 ” Apparatus for Transmitting Electrical Energy), he called it a high-voltage, air-core, self-regenerative resonant transformer that generates very high voltages at high frequency. However, this phrase is no longer in conventional use. This later coil type is the usual device built by modern enthusiasts. It is an air-core, dual-tuned resonant transformer that generates very high voltages at radio frequencies (RF).

The coil achieves a great gain in voltage by transferring energy from one resonant circuit (the primary) to the other (the secondary) o 🔗 External reference