The General Electric XT-1-A AM transmitter

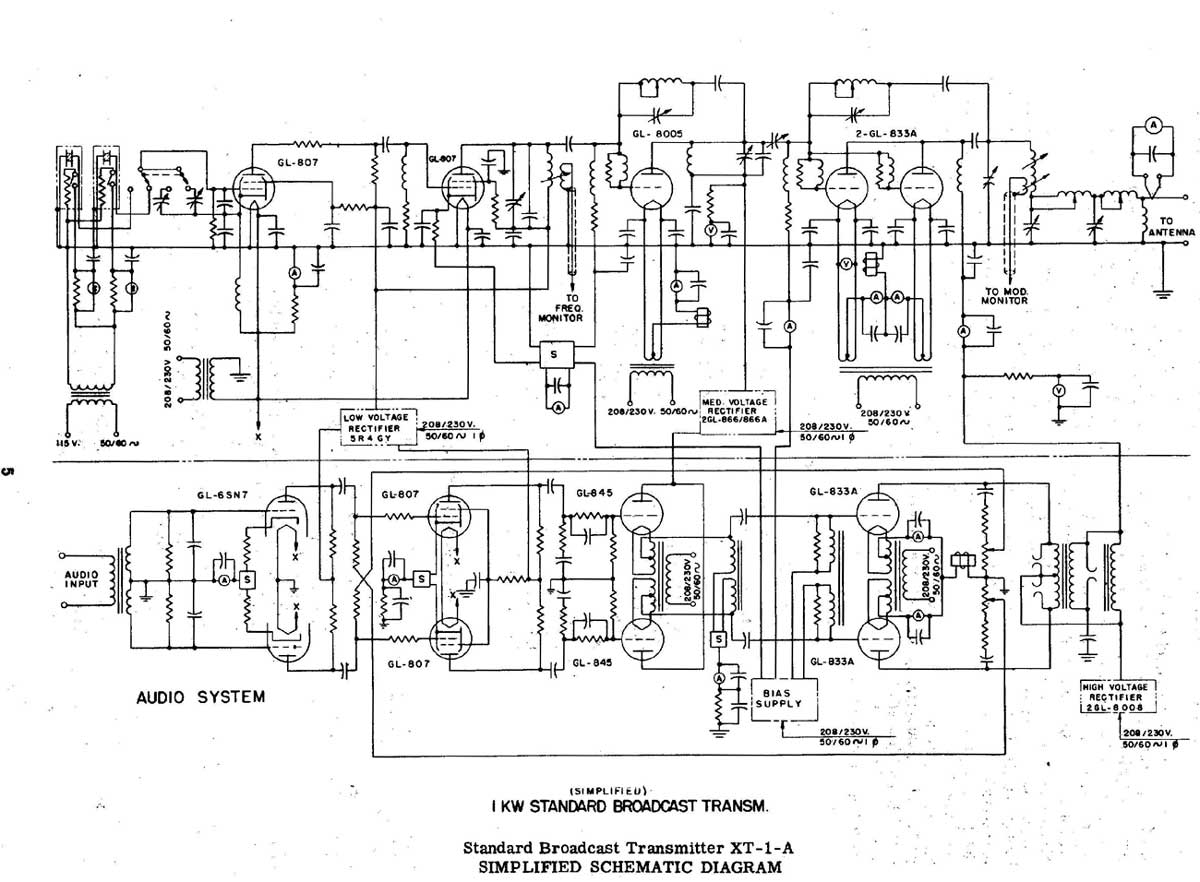

In the past, when AM radio was dominant, significant resources were allocated to the development of transmitting equipment. The GE BTA-25 transmitter from that era exemplified this commitment, featuring a robust construction. During a repair of the Harris MW-50A main transmitter, the GE unit experienced a momentary overload, indicated by a sputter and a brief IPA overload, before resuming operation. Upon inspection of the IPA cabinet, it was discovered that a mica capacitor had been completely damaged. This capacitor was part of the tuning circuit, yet the transmitter continued functioning due to the remaining capacitance in the circuit. Similar to other 1 kW AM transmitter designs, this unit employs the well-regarded 833A triode. This tube offers certain advantages, notably the elimination of the need for additional circuits for power amplifier stage neutralization. The full sales brochure is available in a medium-sized PDF format. Production of this transmitter took place in Syracuse, NY.

The GE BTA-25 transmitter is a notable piece of equipment in the history of AM broadcasting, characterized by its robust design and reliable performance. The transmitter employs the 833A triode, a high-power vacuum tube that is well-suited for radio frequency amplification. The 833A triode is known for its high gain and efficiency, making it an ideal choice for 1 kW AM transmitters. Its design eliminates the need for complex neutralization circuits, simplifying the overall transmitter architecture and enhancing reliability.

The tuning circuit of the GE BTA-25 is critical for maintaining optimal operating conditions and ensuring that the transmitter operates at the desired frequency. The presence of a mica capacitor within this circuit is essential for tuning stability and performance. Even when components fail, as evidenced by the blown capacitor incident, the resilience of the circuit can allow for continued operation, albeit potentially at reduced efficiency.

The construction quality of the GE BTA-25 is indicative of the manufacturing standards of the time, with a focus on durability and longevity. This transmitter was built to withstand the rigors of continuous operation, making it a preferred choice for many broadcasters. The production of the GE BTA-25 in Syracuse, NY, highlights the regional significance of electronics manufacturing during that period.

Overall, the GE BTA-25 transmitter represents a significant technological achievement in AM broadcasting, combining robust engineering with effective component selection to deliver reliable performance in various operational conditions.Back in the day when AM was king, no expense was spared on transmitting equipment. I remember the GE BTA-25 transmitter from the same era, it was build like a tank. Once, while we were repairing the Harris MW-50A main transmitter, the old GE burped, sputtered and threw an IPA overload, then returned to air. I looked in the IPA cabinet and found a mica capacitor had been blown in half. It was in the tuning circuit, but apparently there was still enough capacitance in the circuit for the transmitter to keep running. Like other 1 KW AM transmitter designs, this unit uses the venerable 833A triode. There are some advantages of this tube, as extra circuits for PA stage neutralization are not needed.

The full sales brochure can be found here (medium sized. pdf). These were manufactured in Syracuse, NY. 🔗 External reference

The GE BTA-25 transmitter is a notable piece of equipment in the history of AM broadcasting, characterized by its robust design and reliable performance. The transmitter employs the 833A triode, a high-power vacuum tube that is well-suited for radio frequency amplification. The 833A triode is known for its high gain and efficiency, making it an ideal choice for 1 kW AM transmitters. Its design eliminates the need for complex neutralization circuits, simplifying the overall transmitter architecture and enhancing reliability.

The tuning circuit of the GE BTA-25 is critical for maintaining optimal operating conditions and ensuring that the transmitter operates at the desired frequency. The presence of a mica capacitor within this circuit is essential for tuning stability and performance. Even when components fail, as evidenced by the blown capacitor incident, the resilience of the circuit can allow for continued operation, albeit potentially at reduced efficiency.

The construction quality of the GE BTA-25 is indicative of the manufacturing standards of the time, with a focus on durability and longevity. This transmitter was built to withstand the rigors of continuous operation, making it a preferred choice for many broadcasters. The production of the GE BTA-25 in Syracuse, NY, highlights the regional significance of electronics manufacturing during that period.

Overall, the GE BTA-25 transmitter represents a significant technological achievement in AM broadcasting, combining robust engineering with effective component selection to deliver reliable performance in various operational conditions.Back in the day when AM was king, no expense was spared on transmitting equipment. I remember the GE BTA-25 transmitter from the same era, it was build like a tank. Once, while we were repairing the Harris MW-50A main transmitter, the old GE burped, sputtered and threw an IPA overload, then returned to air. I looked in the IPA cabinet and found a mica capacitor had been blown in half. It was in the tuning circuit, but apparently there was still enough capacitance in the circuit for the transmitter to keep running. Like other 1 KW AM transmitter designs, this unit uses the venerable 833A triode. There are some advantages of this tube, as extra circuits for PA stage neutralization are not needed.

The full sales brochure can be found here (medium sized. pdf). These were manufactured in Syracuse, NY. 🔗 External reference