Timers for Rocket Ejection

This can be a thin strand of wire, like one of the copper "hairs" from a section of lamp cord, which is wired to the altimeter by terminals somewhere on the rocket body and anchored to the launch stand at some point. When the rocket takes off, the stand holds the wire back. If the wire breaks, the circuit is interrupted, and the timer starts timing. A potential downside is that a wire that is too strong could hold a small rocket back. Dangling wires could contact each other in flight, restarting the countdown and causing late ejection. Another method involves running current through a section of solder located under the rocket nozzle. The exhaust heat melts the solder, provided it remains in place; however, the heat could also melt copper easily. An alternative is to place a reed switch in the rocket, with a magnet on the launch rod to keep it closed. As the rocket leaves the rod, the switch opens, starting the timer. Some individuals mount an audio-type earphone jack in the tail end of the rocket, facing down. A tethered plug is inserted into the jack, maintaining a closed circuit. This plug is tied to the launch stand, so when the rocket takes off, the plug is jerked out, breaking the circuit and starting the countdown. A downside to this method is that these jacks are not designed for high acceleration, so reliability under rocket conditions must be monitored. Additionally, exhaust products are corrosive and may cause flaky connections with any electrical connector mounted near the motor. Terminals on the side of the rocket can be connected with a strong wire using small alligator clips, similar to those used for Estes ignitors. The wire is firmly mounted to the test stand, so when the rocket takes off, the clips slip off the terminals, breaking the connection and starting the timer. It is important for the rocket to have some form of on/off switch that can be actuated on the pad. The timer should remain off until the last moment, switching on just before returning to the launch control area. Various alternatives exist, and the downside of the break-wire method is that it requires something external to the rocket. An internal switch that senses the motion of the rocket can be used to trigger the timer. G-switches can be mounted on the circuit board, keeping everything inside the rocket. These switches can be purchased, such as one from Perfectflite for $8. Many rocketeers use a common micro-switch, attaching a weight to the lever and orienting it so that when the rocket takes off, the lever closes the circuit, starting the timer. The g-switch is frequently used with the 556 dual-timer chip, which allows a single pulse or momentary circuit closure to initiate the timer sequence. A potential downside is that dropping the rocket or moving it abruptly could start the g-switch timer countdown. More sophisticated timers often have internal protection against such events, but caution is still advised. One of the resistors (50K) is adjustable (potentiometer), allowing the user to change the rate at which the capacitor fills, thereby adjusting the length of the delay. A transistor (2SB) monitors the voltage in the capacitor, and when it reaches a specific trigger voltage, it allows current to flow freely. The use of a relay is not recommended in rocketry timers, as it is a mechanical device that could be actuated by acceleration, heavy vibration, or rough handling. Instead, a solid-state device such as a MOSFET (Metal-Oxide Semiconductor Field Effect Transistor) should be employed. Components can be sourced individually, and their assembly can be done using an electronics project board or by creating a printed circuit board (PCB) independently. Kits for etching PCBs are available from various electronics suppliers.

The described circuit functions primarily as a timing mechanism for model rockets, utilizing various methods for circuit interruption to initiate a countdown timer upon launch. The initial setup involves a thin wire connected to the altimeter, which, when pulled, breaks the circuit and triggers the timer. The design must consider various factors affecting reliability, such as the strength of the wire and the potential for unintended circuit closures due to vibration or contact between wires during flight.

Alternative methods include the use of solder that melts under exhaust heat, reed switches activated by magnets, and audio-type jacks that maintain circuit integrity until ejection. Each method has unique advantages and drawbacks, particularly concerning durability and susceptibility to environmental factors like exhaust gases.

For more sophisticated implementations, integrating a g-switch provides an internal solution that senses the rocket's motion, allowing for a more streamlined design. The g-switch can be paired with a 556 dual-timer chip, which is ideal for applications requiring precise timing based on motion detection. The adjustable resistor allows for customization of the timing delay, providing flexibility for different rocket designs and launch conditions.

The selection of solid-state components such as MOSFETs over mechanical relays enhances the reliability of the timer circuit, reducing the risk of false triggering from mechanical vibrations. The overall assembly of the circuit can be achieved through various methods, whether by sourcing individual components or utilizing pre-manufactured PCBs, ensuring that the final product meets the necessary specifications for reliable operation in a rocket launch environment.This can be a thin strand of wire, like one of the copper "hairs" from a section of lamp cord, which is wired to the altimeter by terminals somewhere on the rocket body and anchored to the launch stand at some point. Rocket takes off, stand holds the wire back. Wire breaks, circuit is interrupted, and timer starts timing. Possible downside: Too strong a wire could hold a small rocket back. Dangling wires could contact each other in flight, restarting the countdown and making for late ejection. b. I`ve heard of those that ran the current through a section of solder which went under the rocket nozzle.

Exhaust heat melts solder, provided that the solder stayed in place. Actually that much heat could melt copper almost as easily. c. Another is to put a reed switch in the rocket, and have a magnet on the launch rod hold it closed. Rocket leaves rod, switch opens, timer starts timing. d. Some folks mount an audio-type earphone jack in the tail end of the rocket, facing down. A tethered plug is inserted in the jack, keeping the circuit closed. The plug is tied to the launch stand, so that when the rocket takes off, the plug is jerked out, the circuit broken, and the timer starts counting down. Possible downside: these jacks are not designed for high acceleration, so their reliability under rocket conditions must be monitored.

Also, exhaust products are corrosive, and may cause flaky connections with any electrical connector mounted near the motor. e. Terminals on the side of the rocket are connected with a strong wire by small alligator clips, like those used for Estes ignitors.

Wire is mounted firmly to test stand, so that when rocket takes off, the wire stays behind - clips slip off the terminals, breaking connection and starting the timer. Obviously, the rocket needs some kind of on/off switch mounted where it can be actuated on the pad. The timer is kept OFF until the last minute, switched on just before you walk back to the launch control area.

There are several other alternatives, no doubt some of them already occur to you. But the downside of the break-wire is that it requires something external to the rocket. . This is an internal switch that senses the motion of the rocket to trigger the timer. G-switches can be mounted on the circuit board, so that everything is inside the rocket. One can buy such switches - Perfectflite (listed below) has one for $8. Many rocketeers will take a common micro-switch, epoxy a weight to the lever, and orient it in the rocket so that when the rocket takes off, the lever closes the circuit, starting the timer. The g-switch is more often used withthe 556 dual-timer chip. This chip allows a single "pulse" or momentary circuit closure to start the timer sequence going. Possible downside: Dropping the rocket, or moving it abruptly, could start a g-switch timer counting down.

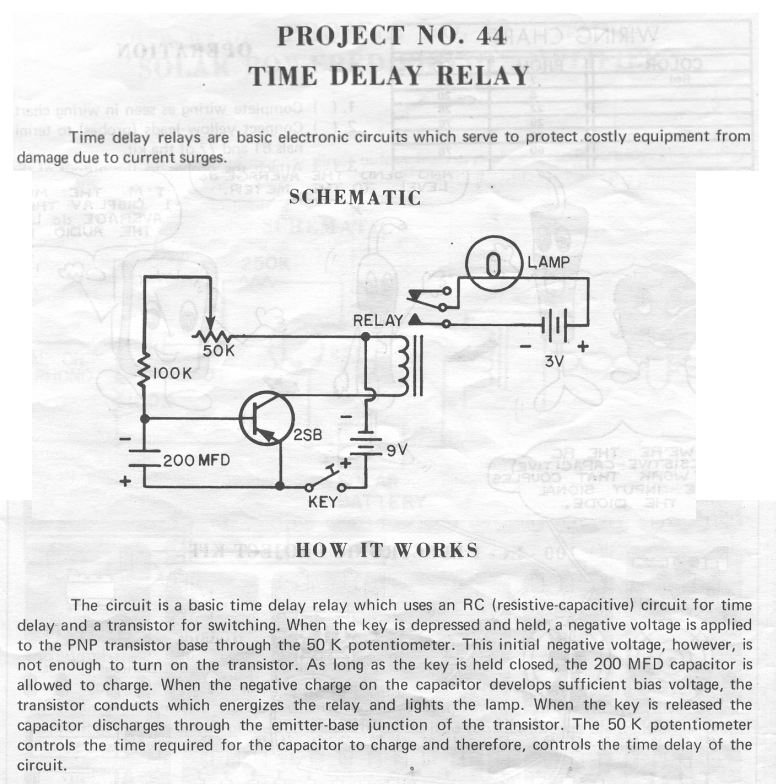

The more sophisticated timers often have internal protection against such events, but caution is still advised. 3. One of the resistors (50K) is adjustable (potentiometer) allowing user to change the rate at which the capacitor fills, thus adjusting the length of the delay.

4. Transistor (2SB) "reads" the the voltage in the capacitor, and when it reaches a certain (trigger) voltage, "opens the gates" and lets the current flow freely. (1) Use of a relay is not recommended in rocketry timers. The relay is a mechanical device that could be actuated by acceleration, heavy vibration, or rough handling.

A solid-state device such asMOSFET (Metal-Oxide Semiconductor Field Effect Transistor) should be used instead. 1. Get the parts yourself, figure out how they go together from the schematic and diagrams, and put it together with either an electronics project board, or by making the printed-circuit board yourself.

Kits for etching your own PC boards are available at Radio Shack and other electronics suppliers. 2. Buy the printed circuit board from Johnny, and get the part 🔗 External reference

The described circuit functions primarily as a timing mechanism for model rockets, utilizing various methods for circuit interruption to initiate a countdown timer upon launch. The initial setup involves a thin wire connected to the altimeter, which, when pulled, breaks the circuit and triggers the timer. The design must consider various factors affecting reliability, such as the strength of the wire and the potential for unintended circuit closures due to vibration or contact between wires during flight.

Alternative methods include the use of solder that melts under exhaust heat, reed switches activated by magnets, and audio-type jacks that maintain circuit integrity until ejection. Each method has unique advantages and drawbacks, particularly concerning durability and susceptibility to environmental factors like exhaust gases.

For more sophisticated implementations, integrating a g-switch provides an internal solution that senses the rocket's motion, allowing for a more streamlined design. The g-switch can be paired with a 556 dual-timer chip, which is ideal for applications requiring precise timing based on motion detection. The adjustable resistor allows for customization of the timing delay, providing flexibility for different rocket designs and launch conditions.

The selection of solid-state components such as MOSFETs over mechanical relays enhances the reliability of the timer circuit, reducing the risk of false triggering from mechanical vibrations. The overall assembly of the circuit can be achieved through various methods, whether by sourcing individual components or utilizing pre-manufactured PCBs, ensuring that the final product meets the necessary specifications for reliable operation in a rocket launch environment.This can be a thin strand of wire, like one of the copper "hairs" from a section of lamp cord, which is wired to the altimeter by terminals somewhere on the rocket body and anchored to the launch stand at some point. Rocket takes off, stand holds the wire back. Wire breaks, circuit is interrupted, and timer starts timing. Possible downside: Too strong a wire could hold a small rocket back. Dangling wires could contact each other in flight, restarting the countdown and making for late ejection. b. I`ve heard of those that ran the current through a section of solder which went under the rocket nozzle.

Exhaust heat melts solder, provided that the solder stayed in place. Actually that much heat could melt copper almost as easily. c. Another is to put a reed switch in the rocket, and have a magnet on the launch rod hold it closed. Rocket leaves rod, switch opens, timer starts timing. d. Some folks mount an audio-type earphone jack in the tail end of the rocket, facing down. A tethered plug is inserted in the jack, keeping the circuit closed. The plug is tied to the launch stand, so that when the rocket takes off, the plug is jerked out, the circuit broken, and the timer starts counting down. Possible downside: these jacks are not designed for high acceleration, so their reliability under rocket conditions must be monitored.

Also, exhaust products are corrosive, and may cause flaky connections with any electrical connector mounted near the motor. e. Terminals on the side of the rocket are connected with a strong wire by small alligator clips, like those used for Estes ignitors.

Wire is mounted firmly to test stand, so that when rocket takes off, the wire stays behind - clips slip off the terminals, breaking connection and starting the timer. Obviously, the rocket needs some kind of on/off switch mounted where it can be actuated on the pad. The timer is kept OFF until the last minute, switched on just before you walk back to the launch control area.

There are several other alternatives, no doubt some of them already occur to you. But the downside of the break-wire is that it requires something external to the rocket. . This is an internal switch that senses the motion of the rocket to trigger the timer. G-switches can be mounted on the circuit board, so that everything is inside the rocket. One can buy such switches - Perfectflite (listed below) has one for $8. Many rocketeers will take a common micro-switch, epoxy a weight to the lever, and orient it in the rocket so that when the rocket takes off, the lever closes the circuit, starting the timer. The g-switch is more often used withthe 556 dual-timer chip. This chip allows a single "pulse" or momentary circuit closure to start the timer sequence going. Possible downside: Dropping the rocket, or moving it abruptly, could start a g-switch timer counting down.

The more sophisticated timers often have internal protection against such events, but caution is still advised. 3. One of the resistors (50K) is adjustable (potentiometer) allowing user to change the rate at which the capacitor fills, thus adjusting the length of the delay.

4. Transistor (2SB) "reads" the the voltage in the capacitor, and when it reaches a certain (trigger) voltage, "opens the gates" and lets the current flow freely. (1) Use of a relay is not recommended in rocketry timers. The relay is a mechanical device that could be actuated by acceleration, heavy vibration, or rough handling.

A solid-state device such asMOSFET (Metal-Oxide Semiconductor Field Effect Transistor) should be used instead. 1. Get the parts yourself, figure out how they go together from the schematic and diagrams, and put it together with either an electronics project board, or by making the printed-circuit board yourself.

Kits for etching your own PC boards are available at Radio Shack and other electronics suppliers. 2. Buy the printed circuit board from Johnny, and get the part 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713