V3.0 MS Build With Pics

Warning: Undefined array key "extension" in /var/www/html/nextgr/view-circuit.php on line 477

Deprecated: strtolower(): Passing null to parameter #1 ($string) of type string is deprecated in /var/www/html/nextgr/view-circuit.php on line 477

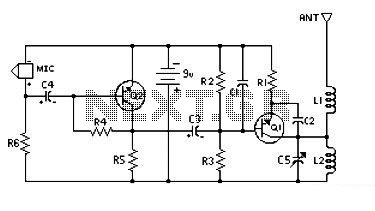

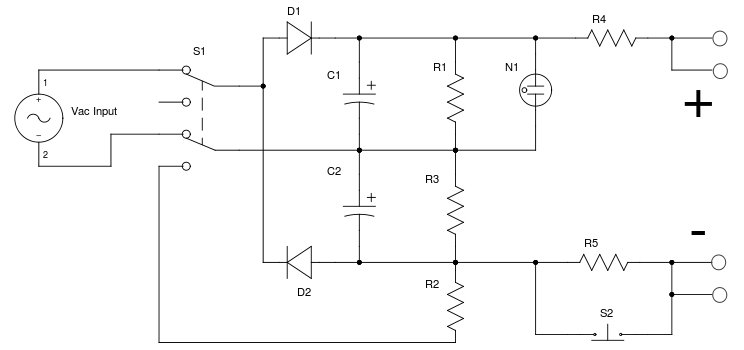

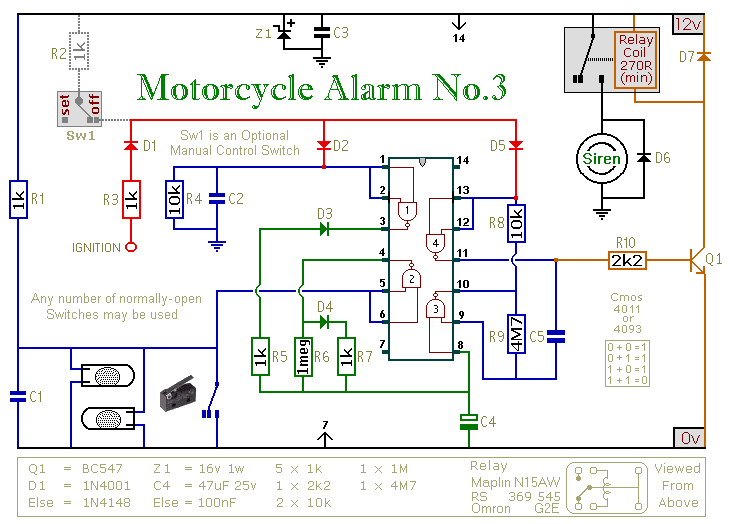

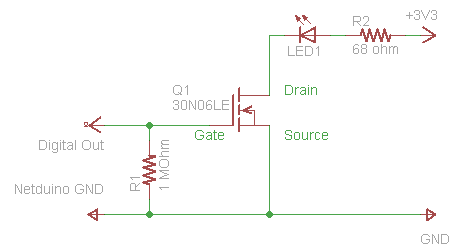

This version is V3.0, designed for TII use, featuring a stock FC ignition, a modified 24-2 style CAS, and a 3-bar MAP sensor. It has passed testing on the stimulator, indicating proper functionality. Future tests will be conducted on a test bench using an actual 24-2 style CAS for further verification. All wiring is done via a DB-37 connector, eliminating the need for additional connectors. This is the first V3.0 build, although several V2.2 and earlier versions have been constructed. The V2.2 is noted to be easier to build due to less population on the board and more generous pad spacing, particularly for the small NPN transistors. Feedback is welcomed from those who have previously constructed V3.0 units regarding any anomalies. The only modification made to the board involved adding three pull-up resistors (the brown DALE resistors seen vertically in the initial pictures) and associated wiring to route the ignition signals through the DB-37 connector. The prototype area was utilized as a pass-through to connect the top and bottom sides of the board, with wires run along the underside. The wiring configuration should adhere to the attached wiring schematic. Caution is advised when using the 12-1 (24-2) setup, particularly with the built-in VR sensor conditioner, as it may be more prone to noise. The missing tooth decoder has shown increased sensitivity to noise based on experience with the 12-1 setup in a 20-valve 4AGE engine. Efforts to mitigate electromagnetic interference (EMI) on signal wires have been necessary, including ensuring quality ground connections and isolating relay grounds from the MS grounds. Adjustments to the threshold potentiometer on the MS have also been required to eliminate noise at specific RPMs (6800-7000 RPM) when the relay controlling VVT disengages. Clarification is sought regarding the susceptibility of the 12-1 setup to noise compared to the stock CAS, as the input hardware is identical for both configurations. It is noted that the V3.0 built-in VR circuit may be more sensitive to noise than the LM1815 circuit due to its adaptive hysteresis feature. Proper grounding and shielding, along with adherence to VR circuit potentiometer adjustment procedures, are expected to ensure smooth operation. Attached images illustrate the necessary board modifications for ignition output support and may be added to the FAQ as a supplement to the earlier V2.2 board images. The quality of VR wiring is emphasized as crucial for achieving a noise-free signal, with success reported when using intercom wire (twisted pair within a braid and foil shield) and ensuring all electrical connections are unified to a common ground. Concerns regarding the V3 VR circuit and prior experiences with the 1815 circuits, particularly interference from a nearby AM radio station, have been noted. Instances of tachometer spikes due to random noise have been experienced, reaching readings of 20,000 RPM when the actual RPM is only 6800. Misfires on the second trigger wheel decoder may occur if the NE conditioner receives excessive pulses, and tach spikes can arise if the G conditioner is subjected to more pulses than intended.

The V3.0 circuit design is structured to support advanced ignition control and sensor integration. It utilizes a DB-37 connector for streamlined wiring, facilitating connections to various input and output devices. The board design incorporates pull-up resistors to stabilize signal integrity, particularly for ignition signal outputs. The inclusion of a 3-bar MAP sensor enhances the engine management capabilities by allowing for more precise monitoring of manifold pressure, essential for optimizing fuel delivery and ignition timing.

The modified 24-2 CAS is designed to provide reliable crankshaft position sensing, and the implementation of the built-in VR sensor conditioner is aimed at improving the accuracy of the signal processing. However, attention must be paid to potential noise interference, especially in environments with high electromagnetic interference, which can adversely affect the performance of the missing tooth decoder. Grounding practices are critical; it is recommended that all grounds be connected to a single point to minimize ground loops and potential noise pickup.

The use of twisted pair wiring, particularly in the context of the VR sensor connections, is encouraged to combat noise susceptibility. Shielding techniques, such as utilizing foil or braided wire, can provide additional protection against external electromagnetic fields. The circuit's design should also incorporate adequate filtering and decoupling capacitors to further enhance signal stability.

In summary, the V3.0 circuit represents a sophisticated evolution in ignition control technology, designed to accommodate modern engine management requirements while addressing the challenges posed by noise and electromagnetic interference. Proper assembly and attention to detail during installation are paramount to achieving optimal performance and reliability.This one is V3. 0, for TII use, stock FC ignition, 24-2 style modified CAS, and 3-bar MAP sensor. It tests fine on the stim, so I`m hoping all is well. I`ll power up my test bench later, and test with an actual 24-2 style CAS just to be sure. All wiring is via DB-37, no extra connectors needed. This is my first V3. 0 build, although I`ve built several V2. 2 and earlier styles. V2. 2 is a much easier build, as the board is less populated, and pad spacing, particularly on the little NPN transistors, is much more generous. Those of you that have built V3. 0 units before, let me know if anything looks odd. The only modification made to the board is the addition of the three pull-up resistors (those brown `DALE` resistors seen running vertical in the first couple pics), and associated wiring to bring the ignition signals out the DB37.

See attached pics for details. I used the prototype area as a pass-through, to get from the top to bottom side of the board, and ran the wires along the underside. The wiring should match the attached wiring schematic. Hey Renns, one thing you might want to be careful with using the 12-1 (24-2) setup, especially with the built-in VR sensor conditioner is noise.

The missing tooth decoder is a lot more sensitive to noise so far in my experience (using 12-1 in my 20 valve 4age on the ae86, and from what people using it that way have been telling me about their setups). I`ve had to do a lot to clean up EMI on the signal wires, make extra sure my grounds are good, make sure my relay grounds for various relay-driven components are separate from my MS grounds, and I`ve had to tinker with the threshold Potentiometer on the MS.

All that to get rid of a small amount of noise right at 6800-7000 rpms where the relay I`m running my VVT with turns off. Are you saying the 12-1 is more susceptible to noise than the using the stock CAS I`m not clear on that, as the input hardware is identical with missing tooth and 2nd trigger.

Did you mean the V3. 0 built-in VR circuit is more susceptible to noise than the LM1815 circuit That I can see, given the adaptive hysteresis feature of that chip. Hopefully with the proper grounds and shielding you mention, and following the VR circuit pot adjustment procedures here the install will run smoothly.

Hopefully these pics clarify the board mods required to support ignition output. Feel free to add these pic(s) to the FAQ if you like to supplement that older V2. 2 board pic. I`ve found the VR wiring to be the most important part in order to assure a noise-free signal. I`ve had zero problems using that intercom wire I`ve spoken of previously (twisted pair inside a braid and foil shield) as well as meticulous attention to being certain everything electrically connected is directly connected to a unified ground. This is regarding the v3 VR circuit. I`ve never had much luck with the 1815 circuits, I think primarily due to a 50KW AM radio station antenna 1/2 mile away from my home workshop.

They work fine as soon as I get away from that antenna. With a scope, I can see the AM signal in the inputs and it seems to confuse the 1815 in some way. 3) If you have a lot of random noise at one point or another, it`s easier to get nasty tach-spikes. I`ve seen as high as 20000 rpms when I`m really only at 6800. You can still get misses on the 2nd trigger wheel decoder if the Ne conditioner gets more pulses than it should. and you can still get tach spikes if the G conditioner gets more pulses tha 🔗 External reference

The V3.0 circuit design is structured to support advanced ignition control and sensor integration. It utilizes a DB-37 connector for streamlined wiring, facilitating connections to various input and output devices. The board design incorporates pull-up resistors to stabilize signal integrity, particularly for ignition signal outputs. The inclusion of a 3-bar MAP sensor enhances the engine management capabilities by allowing for more precise monitoring of manifold pressure, essential for optimizing fuel delivery and ignition timing.

The modified 24-2 CAS is designed to provide reliable crankshaft position sensing, and the implementation of the built-in VR sensor conditioner is aimed at improving the accuracy of the signal processing. However, attention must be paid to potential noise interference, especially in environments with high electromagnetic interference, which can adversely affect the performance of the missing tooth decoder. Grounding practices are critical; it is recommended that all grounds be connected to a single point to minimize ground loops and potential noise pickup.

The use of twisted pair wiring, particularly in the context of the VR sensor connections, is encouraged to combat noise susceptibility. Shielding techniques, such as utilizing foil or braided wire, can provide additional protection against external electromagnetic fields. The circuit's design should also incorporate adequate filtering and decoupling capacitors to further enhance signal stability.

In summary, the V3.0 circuit represents a sophisticated evolution in ignition control technology, designed to accommodate modern engine management requirements while addressing the challenges posed by noise and electromagnetic interference. Proper assembly and attention to detail during installation are paramount to achieving optimal performance and reliability.This one is V3. 0, for TII use, stock FC ignition, 24-2 style modified CAS, and 3-bar MAP sensor. It tests fine on the stim, so I`m hoping all is well. I`ll power up my test bench later, and test with an actual 24-2 style CAS just to be sure. All wiring is via DB-37, no extra connectors needed. This is my first V3. 0 build, although I`ve built several V2. 2 and earlier styles. V2. 2 is a much easier build, as the board is less populated, and pad spacing, particularly on the little NPN transistors, is much more generous. Those of you that have built V3. 0 units before, let me know if anything looks odd. The only modification made to the board is the addition of the three pull-up resistors (those brown `DALE` resistors seen running vertical in the first couple pics), and associated wiring to bring the ignition signals out the DB37.

See attached pics for details. I used the prototype area as a pass-through, to get from the top to bottom side of the board, and ran the wires along the underside. The wiring should match the attached wiring schematic. Hey Renns, one thing you might want to be careful with using the 12-1 (24-2) setup, especially with the built-in VR sensor conditioner is noise.

The missing tooth decoder is a lot more sensitive to noise so far in my experience (using 12-1 in my 20 valve 4age on the ae86, and from what people using it that way have been telling me about their setups). I`ve had to do a lot to clean up EMI on the signal wires, make extra sure my grounds are good, make sure my relay grounds for various relay-driven components are separate from my MS grounds, and I`ve had to tinker with the threshold Potentiometer on the MS.

All that to get rid of a small amount of noise right at 6800-7000 rpms where the relay I`m running my VVT with turns off. Are you saying the 12-1 is more susceptible to noise than the using the stock CAS I`m not clear on that, as the input hardware is identical with missing tooth and 2nd trigger.

Did you mean the V3. 0 built-in VR circuit is more susceptible to noise than the LM1815 circuit That I can see, given the adaptive hysteresis feature of that chip. Hopefully with the proper grounds and shielding you mention, and following the VR circuit pot adjustment procedures here the install will run smoothly.

Hopefully these pics clarify the board mods required to support ignition output. Feel free to add these pic(s) to the FAQ if you like to supplement that older V2. 2 board pic. I`ve found the VR wiring to be the most important part in order to assure a noise-free signal. I`ve had zero problems using that intercom wire I`ve spoken of previously (twisted pair inside a braid and foil shield) as well as meticulous attention to being certain everything electrically connected is directly connected to a unified ground. This is regarding the v3 VR circuit. I`ve never had much luck with the 1815 circuits, I think primarily due to a 50KW AM radio station antenna 1/2 mile away from my home workshop.

They work fine as soon as I get away from that antenna. With a scope, I can see the AM signal in the inputs and it seems to confuse the 1815 in some way. 3) If you have a lot of random noise at one point or another, it`s easier to get nasty tach-spikes. I`ve seen as high as 20000 rpms when I`m really only at 6800. You can still get misses on the 2nd trigger wheel decoder if the Ne conditioner gets more pulses than it should. and you can still get tach spikes if the G conditioner gets more pulses tha 🔗 External reference