VFD Clock

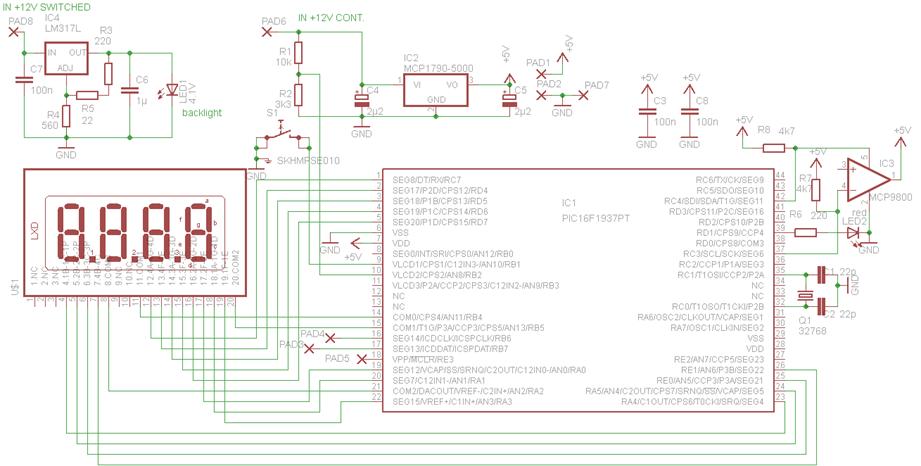

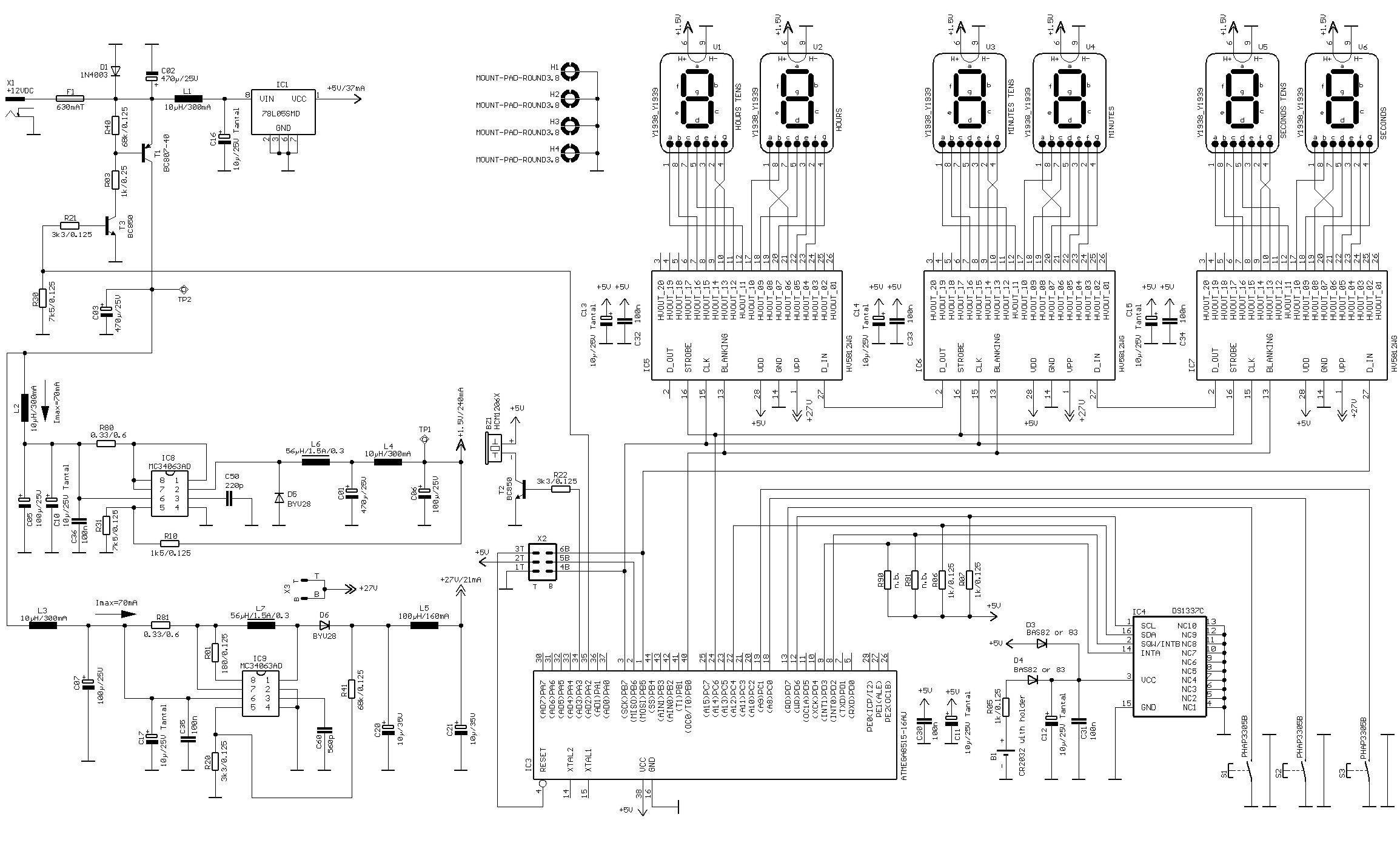

A vacuum fluorescent display (VFD) tube is a type of tube that consists of a hot cathode (filaments) and anodes (phosphor) within a high vacuum environment enclosed in a glass envelope. This clock utilizes tube types 8843 or 8894, manufactured by Sylvania in the early seventies. The cathode comprises fine tungsten wires coated with alkaline earth metal oxides, which emit electrons when heated by an electric current. When electrons strike the phosphor-coated plates, they fluoresce, producing light to indicate the seven segments used in these tubes. Electrons can only illuminate a specific plate element if that plate is at a positive potential relative to the cathode. Unlike other VFD displays, these tubes do not have a grid. Power Down Mode allows the tubes and power supply to be completely turned off for a user-programmed duration to conserve energy and extend the lifespan of the tubes. The clock also features RTC drift compensation, addressing the drift inherent in every real-time clock (RTC) chip. This drift is influenced by ambient temperature, buffer battery voltage, aging, and other factors. The drift compensation feature enables adjustment of this drift to nearly zero.

The vacuum fluorescent display (VFD) tube operates through a series of fundamental principles involving thermionic emission and fluorescence. The hot cathode, constructed of fine tungsten wires, is heated to a high temperature, allowing it to emit electrons due to thermionic emission. The emitted electrons travel toward the anodes, which are coated with phosphorescent materials. When these electrons collide with the phosphor, light is emitted, illuminating the segments of the display.

The design of the VFD tube allows for a more straightforward control mechanism compared to other types of displays, as it lacks a grid structure. This absence simplifies the circuitry required for operation, enabling direct control of the anode voltages to achieve the desired illumination for each segment. The requirement for a positive potential at the anode ensures that only the designated segments light up when activated.

In terms of power management, the Power Down Mode feature is particularly beneficial for energy conservation. By allowing the user to program a shutdown period, the clock can significantly reduce power consumption during inactive periods, thereby prolonging the operational life of the display tubes. This feature is especially useful in applications where the display is not needed continuously.

The RTC drift compensation mechanism is crucial for maintaining accurate timekeeping. Real-time clocks are subject to various environmental factors that can cause time drift. The compensation feature in this clock system monitors these variables and adjusts the timekeeping mechanism accordingly, ensuring high precision over extended periods. This is achieved through software algorithms that account for changes in temperature, battery voltage, and other influences, effectively maintaining the accuracy of the time displayed by the VFD.

Overall, the vacuum fluorescent display clock represents a blend of innovative display technology and advanced timekeeping features, making it a reliable choice for applications requiring both visual clarity and precision timing.A vacuum fluorescent display (VFD) tube is a type of tube which consists of a hot cathode (filaments), anodes (phosphor) under a high vacuum condition in a glass envelope. This clock uses tube types 8843 or 8894 made by Sylvania in the early seventies. The cathode is made up of fine tungsten wires, coated by alkaline earth metal oxides, which emit electrons when heated by an electric current. If electrons impinge on the phosphor-coated plates, they fluoresce, emitting light to indicate the 7-segments used in this tubes. Electrons can only reach (and "illuminate") a given plate element if the plate is at a positive potential with respect to the cathode.

They have no grid compared to other VFD displays. Power Down Mode: tubes and supply can be totally switched off for a user programmed period in order to save energy and increase life expectancy of the tubes RTC drift compensation: Every RTC chip (RTC=Real Time Clock) does have a drift. This drift depends to the ambient temperature, buffer battery voltage, aging and other factors. This clock has a feature called drift compensation which allows compensating that drift nearly to zero.

🔗 External reference

The vacuum fluorescent display (VFD) tube operates through a series of fundamental principles involving thermionic emission and fluorescence. The hot cathode, constructed of fine tungsten wires, is heated to a high temperature, allowing it to emit electrons due to thermionic emission. The emitted electrons travel toward the anodes, which are coated with phosphorescent materials. When these electrons collide with the phosphor, light is emitted, illuminating the segments of the display.

The design of the VFD tube allows for a more straightforward control mechanism compared to other types of displays, as it lacks a grid structure. This absence simplifies the circuitry required for operation, enabling direct control of the anode voltages to achieve the desired illumination for each segment. The requirement for a positive potential at the anode ensures that only the designated segments light up when activated.

In terms of power management, the Power Down Mode feature is particularly beneficial for energy conservation. By allowing the user to program a shutdown period, the clock can significantly reduce power consumption during inactive periods, thereby prolonging the operational life of the display tubes. This feature is especially useful in applications where the display is not needed continuously.

The RTC drift compensation mechanism is crucial for maintaining accurate timekeeping. Real-time clocks are subject to various environmental factors that can cause time drift. The compensation feature in this clock system monitors these variables and adjusts the timekeeping mechanism accordingly, ensuring high precision over extended periods. This is achieved through software algorithms that account for changes in temperature, battery voltage, and other influences, effectively maintaining the accuracy of the time displayed by the VFD.

Overall, the vacuum fluorescent display clock represents a blend of innovative display technology and advanced timekeeping features, making it a reliable choice for applications requiring both visual clarity and precision timing.A vacuum fluorescent display (VFD) tube is a type of tube which consists of a hot cathode (filaments), anodes (phosphor) under a high vacuum condition in a glass envelope. This clock uses tube types 8843 or 8894 made by Sylvania in the early seventies. The cathode is made up of fine tungsten wires, coated by alkaline earth metal oxides, which emit electrons when heated by an electric current. If electrons impinge on the phosphor-coated plates, they fluoresce, emitting light to indicate the 7-segments used in this tubes. Electrons can only reach (and "illuminate") a given plate element if the plate is at a positive potential with respect to the cathode.

They have no grid compared to other VFD displays. Power Down Mode: tubes and supply can be totally switched off for a user programmed period in order to save energy and increase life expectancy of the tubes RTC drift compensation: Every RTC chip (RTC=Real Time Clock) does have a drift. This drift depends to the ambient temperature, buffer battery voltage, aging and other factors. This clock has a feature called drift compensation which allows compensating that drift nearly to zero.

🔗 External reference