white lights

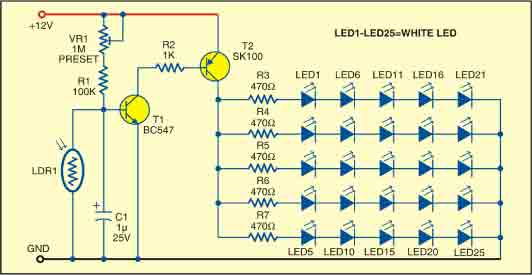

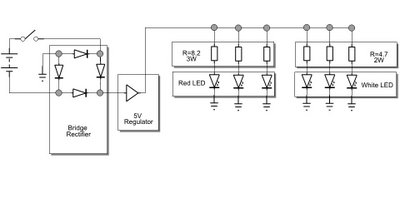

The white LEDs have varying voltage and current requirements, necessitating the use of different resistors. A parts list will be provided. The design concept is similar to previous iterations, but the white LEDs are configured differently due to their dedicated heatsinks. The two bullet lights will serve as smaller side lamps, while a larger bullet headlight will act as the main headlight. The assembly process involved opening the unit, where the light bulb was removed, but the battery case remained intact due to its riveted construction, making removal challenging without potential damage. The rear bullet lights were mounted using existing holes on the trike frame, and wire crimps were employed for connecting the various components of the trike. Black heat-shrink tubing will be applied over the crimps for aesthetic purposes. All wiring, made from black 20-gauge lamp wire and secured with black zip ties, was routed to a bag positioned behind the seat, which is adequately sized to accommodate the electronics box. The lights exhibit high brightness, and battery life is estimated at approximately 2.5 hours, although testing has not yet confirmed this duration, as batteries are typically recharged after each ride.

The circuit design involves the integration of multiple white LEDs, each with specific voltage and current ratings, which necessitates careful selection of resistors to ensure optimal performance and prevent damage to the LEDs. The use of heatsinks is crucial for thermal management, as white LEDs tend to generate more heat compared to other colors. The smaller side lamps will be powered by lower-rated LEDs, while the main headlight will utilize higher-rated LEDs to achieve the desired brightness.

The mounting of the rear bullet lights on the trike frame is facilitated by pre-existing holes, which simplifies installation and ensures stability during operation. The wiring connections are made using wire crimps, which provide reliable electrical continuity. The application of black heat-shrink tubing over these connections enhances the durability of the circuit by protecting against moisture and physical damage, while also improving the overall aesthetic.

The choice of 20-gauge lamp wire is suitable for this application, as it balances flexibility and current-carrying capacity. The use of zip ties for wire management ensures that the wiring remains organized and secure, reducing the risk of entanglement or accidental disconnection during operation. The electronics box, housed in a bag behind the seat, is designed to be compact yet functional, providing adequate space for the necessary components while maintaining a low profile.

Overall, this lighting system is designed to provide effective illumination for the trike, with careful consideration given to the electrical specifications and physical layout to ensure both performance and reliability.The white LEDs have different voltage and current requirements so they will need different resistors. So I`ll begin with a parts list: It`s the same idea as before, only the white LEDs are shaped differently because they have their own heatsink that they are mounted on.

The two bullet lights are going to be smaller side lamps, while a large bullet headlight is going to be the main headlight. Here it is opened up. I removed the light bulb but did not bother removing the battery case, as it was riveted in place and would have been very difficult to remove without damaging anything: I mounted the rear bullet lights using some of the premade mounting holes on the trike frame. Also visible are the wire crimps I used to connect up the whole trike. I am going to put black heat-shrink tubing over the crimps so they`re not quite so visible: Finally, all the wires (made of black 20 gauge lamp wire held in place by black zip ties) were run to a bag strapped behind the seat.

The bag is just the right size to hold the electronics box: And there you go! The lights are bright as heck! I calculated the batteries as lasting around 2. 5 hours, but we haven`t tested the system to that limit yet, as we generally recharge the batteries after every ride anyway. 🔗 External reference

The circuit design involves the integration of multiple white LEDs, each with specific voltage and current ratings, which necessitates careful selection of resistors to ensure optimal performance and prevent damage to the LEDs. The use of heatsinks is crucial for thermal management, as white LEDs tend to generate more heat compared to other colors. The smaller side lamps will be powered by lower-rated LEDs, while the main headlight will utilize higher-rated LEDs to achieve the desired brightness.

The mounting of the rear bullet lights on the trike frame is facilitated by pre-existing holes, which simplifies installation and ensures stability during operation. The wiring connections are made using wire crimps, which provide reliable electrical continuity. The application of black heat-shrink tubing over these connections enhances the durability of the circuit by protecting against moisture and physical damage, while also improving the overall aesthetic.

The choice of 20-gauge lamp wire is suitable for this application, as it balances flexibility and current-carrying capacity. The use of zip ties for wire management ensures that the wiring remains organized and secure, reducing the risk of entanglement or accidental disconnection during operation. The electronics box, housed in a bag behind the seat, is designed to be compact yet functional, providing adequate space for the necessary components while maintaining a low profile.

Overall, this lighting system is designed to provide effective illumination for the trike, with careful consideration given to the electrical specifications and physical layout to ensure both performance and reliability.The white LEDs have different voltage and current requirements so they will need different resistors. So I`ll begin with a parts list: It`s the same idea as before, only the white LEDs are shaped differently because they have their own heatsink that they are mounted on.

The two bullet lights are going to be smaller side lamps, while a large bullet headlight is going to be the main headlight. Here it is opened up. I removed the light bulb but did not bother removing the battery case, as it was riveted in place and would have been very difficult to remove without damaging anything: I mounted the rear bullet lights using some of the premade mounting holes on the trike frame. Also visible are the wire crimps I used to connect up the whole trike. I am going to put black heat-shrink tubing over the crimps so they`re not quite so visible: Finally, all the wires (made of black 20 gauge lamp wire held in place by black zip ties) were run to a bag strapped behind the seat.

The bag is just the right size to hold the electronics box: And there you go! The lights are bright as heck! I calculated the batteries as lasting around 2. 5 hours, but we haven`t tested the system to that limit yet, as we generally recharge the batteries after every ride anyway. 🔗 External reference