Arduino solenoid project behaves strangely when operated on PC power supply

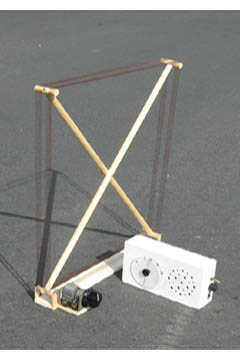

A 9 V DC battery initially powered the solenoid valve effectively. However, the solenoid did not generate sufficient force due to inadequate DC power. A modification was made to use a computer power supply as the power source. Providing +12 V (15.0 A) power from this supply caused the solenoid valve to engage once but then stick to the solenoid body. It operates correctly only when manually pushed away from the body. If the solenoid remains stuck, it does not release even after the power is turned off, requiring manual intervention to separate it. Additionally, a serial print statement in the program indicates activity while the solenoid plunger is adhered to the body. A smaller solenoid operates correctly with the PC power supply when supplied with 5.0 V or 3.0 V. Various delay values were tested, including 10,000 and 100,000, but results remained unchanged. Attempts to modify the HIGH and LOW output durations resulted in the same sticking behavior. It is hypothesized that the solenoid's inductance generates sufficient magnetism to cause the valve to stick, persisting even after power is removed. Furthermore, the solenoid initiates movement when a 12 V lead is connected to the power supply without a ground connection. To test the hypothesis regarding the inductive electromagnetism in the larger solenoid, a smaller solenoid was placed near the energized larger solenoid, causing it to stick. Disconnecting the power resulted in no sticking. This phenomenon may be familiar to those working with solenoids or coils.

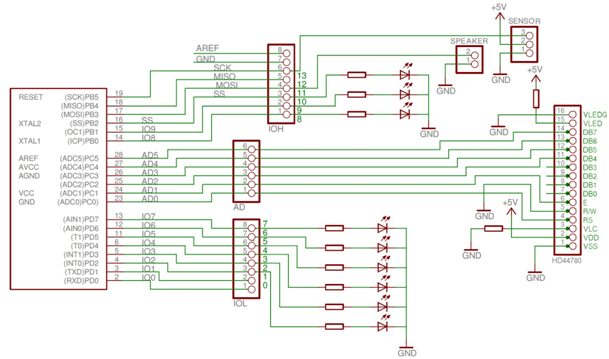

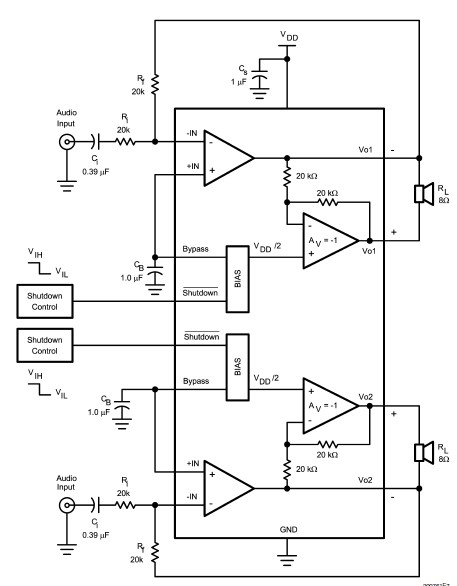

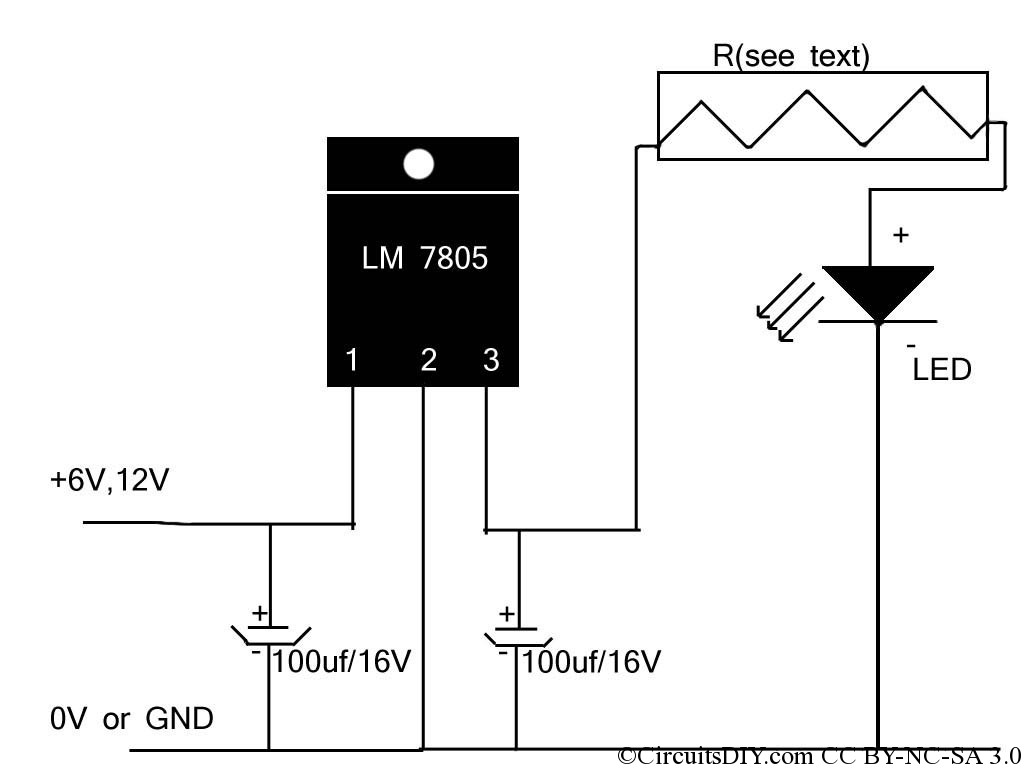

The circuit involves a solenoid valve powered by a modified computer power supply outputting +12 V at 15.0 A. The solenoid operates based on a digital control signal from a microcontroller, such as an Arduino. The control pin (solPin) is set to OUTPUT mode, and a simple loop function is implemented, which alternates the solenoid's state between HIGH and LOW with specified delays.

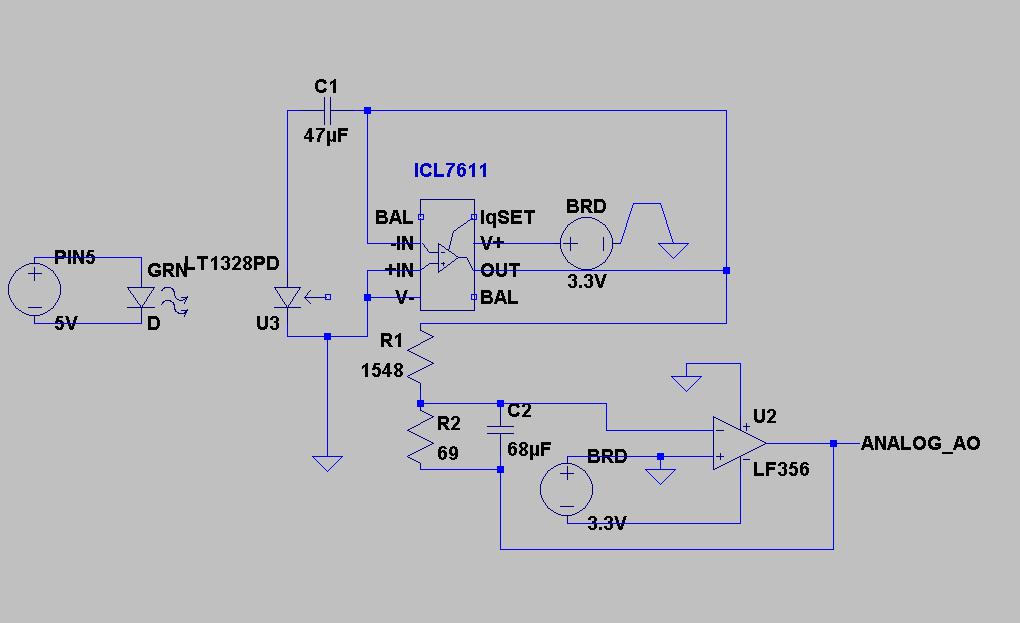

The sticking issue observed may arise from the solenoid's inductive properties. When energized, the solenoid generates a magnetic field strong enough to attract the plunger to the solenoid body. This magnetic retention can persist due to the residual magnetism associated with the solenoid's inductance, which is more pronounced at higher power levels. The phenomenon of the solenoid remaining engaged even after power removal suggests a need for a design consideration to mitigate magnetic retention, possibly through the use of a mechanical return spring or an alternative solenoid design that minimizes magnetic sticking.

To further analyze the circuit's behavior, it is essential to consider the characteristics of the solenoid, including its inductance and resistance, which affect the current flow and electromagnetic behavior. The control logic can also be adjusted to optimize the timing of the solenoid activation, ensuring it fully retracts before re-engagement to prevent sticking. Monitoring the solenoid's performance with various input voltages and configurations will provide insights into its operational limits and help in troubleshooting the sticking issue effectively.With a 9 V DC battery, it worked fine. But because of a less DC power, solenoid was not generating a powerful enough force. I modified a computer power supply as the power source. Now when providing +12 V (15. 0 A) power from it, the solenoid valve is pulled once and then it sticks with the body of solenoid. If I pushed it back, and kept pushing so to not touch the body of solenoid, it works. And if it is sticking with the body, it remains the same even after I turn off power and have to push it to separate. EDIT: The Serial print statement I put in the program is printing while solenoid plunger is stick to body.

Though the small solenoid is working fine with PC power supply too when I provide 5. 0 V OR 3. 0 V to it. I test by changing different delay values. Something like 10000 and 100000, but it gave the same result. I have changed it like giving a small value for HIGH, like 100, and a bigger one, like 10000, for LOW output so that it has enough time to come back, but again with the same result. What I guessed is that the inductance of solenoid because of much current generates magnetism in the body of the solenoid that sticks the valve, and it keeps it sticking even after the power is turned off, so I have to push the valve to separate.

One more thing is that the solenoid starts moving even if I put 12 V lead to the power supply without supplying ground to it. EDIT:I test my hypothesis of electromagnetism created in the body of big solenoid by inductance bec of high power by putting small solenoid near to big solenoid while its powered on and it stick to body of big solenoid.

When I disconnect power, there was no sticking. I think this happening with solenoid plunger too. Is it a phenomenan observed by people working with solenoids or coils int solPin = 13; void setup() { Serial. begin(9600); pinMode(solPin, OUTPUT); } void loop() { Serial. println("Loop start"); digitalWrite(solPin, HIGH); delay(1000); digitalWrite(solPin, LOW); delay(1000); Serial.

println("Loop end"); } 🔗 External reference

The circuit involves a solenoid valve powered by a modified computer power supply outputting +12 V at 15.0 A. The solenoid operates based on a digital control signal from a microcontroller, such as an Arduino. The control pin (solPin) is set to OUTPUT mode, and a simple loop function is implemented, which alternates the solenoid's state between HIGH and LOW with specified delays.

The sticking issue observed may arise from the solenoid's inductive properties. When energized, the solenoid generates a magnetic field strong enough to attract the plunger to the solenoid body. This magnetic retention can persist due to the residual magnetism associated with the solenoid's inductance, which is more pronounced at higher power levels. The phenomenon of the solenoid remaining engaged even after power removal suggests a need for a design consideration to mitigate magnetic retention, possibly through the use of a mechanical return spring or an alternative solenoid design that minimizes magnetic sticking.

To further analyze the circuit's behavior, it is essential to consider the characteristics of the solenoid, including its inductance and resistance, which affect the current flow and electromagnetic behavior. The control logic can also be adjusted to optimize the timing of the solenoid activation, ensuring it fully retracts before re-engagement to prevent sticking. Monitoring the solenoid's performance with various input voltages and configurations will provide insights into its operational limits and help in troubleshooting the sticking issue effectively.With a 9 V DC battery, it worked fine. But because of a less DC power, solenoid was not generating a powerful enough force. I modified a computer power supply as the power source. Now when providing +12 V (15. 0 A) power from it, the solenoid valve is pulled once and then it sticks with the body of solenoid. If I pushed it back, and kept pushing so to not touch the body of solenoid, it works. And if it is sticking with the body, it remains the same even after I turn off power and have to push it to separate. EDIT: The Serial print statement I put in the program is printing while solenoid plunger is stick to body.

Though the small solenoid is working fine with PC power supply too when I provide 5. 0 V OR 3. 0 V to it. I test by changing different delay values. Something like 10000 and 100000, but it gave the same result. I have changed it like giving a small value for HIGH, like 100, and a bigger one, like 10000, for LOW output so that it has enough time to come back, but again with the same result. What I guessed is that the inductance of solenoid because of much current generates magnetism in the body of the solenoid that sticks the valve, and it keeps it sticking even after the power is turned off, so I have to push the valve to separate.

One more thing is that the solenoid starts moving even if I put 12 V lead to the power supply without supplying ground to it. EDIT:I test my hypothesis of electromagnetism created in the body of big solenoid by inductance bec of high power by putting small solenoid near to big solenoid while its powered on and it stick to body of big solenoid.

When I disconnect power, there was no sticking. I think this happening with solenoid plunger too. Is it a phenomenan observed by people working with solenoids or coils int solPin = 13; void setup() { Serial. begin(9600); pinMode(solPin, OUTPUT); } void loop() { Serial. println("Loop start"); digitalWrite(solPin, HIGH); delay(1000); digitalWrite(solPin, LOW); delay(1000); Serial.

println("Loop end"); } 🔗 External reference