ir remote control tester

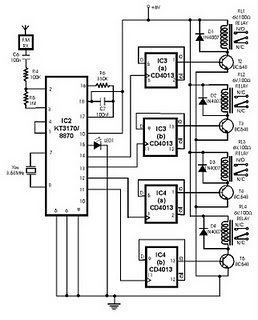

While developing an infrared (IR) extender circuit, a method was required to measure the relative intensities of different infrared light sources. This circuit is the culmination of that research. It utilizes a photodiode, specifically the SFH2030, as the infrared sensor. A MOSFET operational amplifier, CA3140, is employed in differential mode to amplify the current pulses generated by the photodiode. An ordinary colored LED (LED1) illuminates when IR radiation is detected. The output from the operational amplifier, specifically pin 6, can be connected to a multimeter set to measure DC voltage. The strength of infrared remote control signals can be compared based on the multimeter reading; a higher reading indicates a stronger infrared light source. Remote controls were aimed at the sensor from approximately one meter away during testing. For every microamp of current flowing through the photodiode, approximately one volt is produced at the output. Alternative operational amplifiers such as the 741 or LF351 are not suitable for this circuit. While a 12-volt power supply has been used, a 9-volt battery is also compatible.

The infrared extender circuit is designed to effectively measure and compare the intensity of various infrared light sources, notably remote control units. The core components of the circuit include the SFH2030 photodiode, which is sensitive to infrared light, and the CA3140 operational amplifier configured in a differential mode. This configuration allows for precise amplification of the small current generated by the photodiode when exposed to infrared radiation.

The circuit operates by converting the detected infrared light into an electrical signal. When infrared light strikes the photodiode, it generates a current proportional to the intensity of the light. This current is then amplified by the CA3140 operational amplifier, which is essential for achieving a measurable output voltage. The output voltage at pin 6 of the op-amp can be directly correlated to the intensity of the incoming infrared light, making it possible to quantify the strength of various remote control signals.

The inclusion of LED1 serves as a visual indicator of infrared light detection. It provides immediate feedback to the user, signaling that the photodiode is receiving IR radiation. This feature enhances the usability of the circuit during testing and adjustments.

The output voltage can be monitored using a multimeter set to measure DC voltage, allowing for a straightforward comparison of the strength of different infrared remote controls. The circuit is designed to work effectively at a distance of approximately one meter, which is a common range for infrared remote controls. The relationship between the current through the photodiode and the output voltage is linear, with every microamp of current resulting in about one volt at the output.

It is important to note that not all operational amplifiers are suitable for this application. The CA3140 is preferred due to its characteristics, while common alternatives like the 741 or LF351 do not provide the necessary performance for this circuit. Additionally, the circuit can be powered by either a 12-volt power supply or a 9-volt battery, offering flexibility in power sourcing depending on the application requirements.

Overall, this infrared intensity measurement circuit presents a reliable solution for evaluating the performance of infrared light sources, particularly in the context of remote control devices.As I was developing my IR Extender Circuit, I needed to find a way of measuring the relative intensities of different Infra red light sources. This circuit is the result of my research. I have used a photodiode, SFH2030 as an infra red sensor. A MOSFET opamp, CA3140 is used in the differential mode to amplify the pulses of current from the photodi

ode. LED1 is an ordinary coloured led which will light when IR radiation is being received. The output of the opamp, pin 6 may be connected to a multimeter set to read DC volts. Infra red remote control strengths can be compared by the meter reading, the higher the reading, the stronger the infra red light. I aimed different remote control at the sensor from about 1 meter away when comparing results. For every microamp of current through the photodiode, about 1 volt is produced at the output. A 741 or LF351 will not work in this circuit. Although I have used a 12 volt power supply, a 9 volt battery will also work here. 🔗 External reference

The infrared extender circuit is designed to effectively measure and compare the intensity of various infrared light sources, notably remote control units. The core components of the circuit include the SFH2030 photodiode, which is sensitive to infrared light, and the CA3140 operational amplifier configured in a differential mode. This configuration allows for precise amplification of the small current generated by the photodiode when exposed to infrared radiation.

The circuit operates by converting the detected infrared light into an electrical signal. When infrared light strikes the photodiode, it generates a current proportional to the intensity of the light. This current is then amplified by the CA3140 operational amplifier, which is essential for achieving a measurable output voltage. The output voltage at pin 6 of the op-amp can be directly correlated to the intensity of the incoming infrared light, making it possible to quantify the strength of various remote control signals.

The inclusion of LED1 serves as a visual indicator of infrared light detection. It provides immediate feedback to the user, signaling that the photodiode is receiving IR radiation. This feature enhances the usability of the circuit during testing and adjustments.

The output voltage can be monitored using a multimeter set to measure DC voltage, allowing for a straightforward comparison of the strength of different infrared remote controls. The circuit is designed to work effectively at a distance of approximately one meter, which is a common range for infrared remote controls. The relationship between the current through the photodiode and the output voltage is linear, with every microamp of current resulting in about one volt at the output.

It is important to note that not all operational amplifiers are suitable for this application. The CA3140 is preferred due to its characteristics, while common alternatives like the 741 or LF351 do not provide the necessary performance for this circuit. Additionally, the circuit can be powered by either a 12-volt power supply or a 9-volt battery, offering flexibility in power sourcing depending on the application requirements.

Overall, this infrared intensity measurement circuit presents a reliable solution for evaluating the performance of infrared light sources, particularly in the context of remote control devices.As I was developing my IR Extender Circuit, I needed to find a way of measuring the relative intensities of different Infra red light sources. This circuit is the result of my research. I have used a photodiode, SFH2030 as an infra red sensor. A MOSFET opamp, CA3140 is used in the differential mode to amplify the pulses of current from the photodi

ode. LED1 is an ordinary coloured led which will light when IR radiation is being received. The output of the opamp, pin 6 may be connected to a multimeter set to read DC volts. Infra red remote control strengths can be compared by the meter reading, the higher the reading, the stronger the infra red light. I aimed different remote control at the sensor from about 1 meter away when comparing results. For every microamp of current through the photodiode, about 1 volt is produced at the output. A 741 or LF351 will not work in this circuit. Although I have used a 12 volt power supply, a 9 volt battery will also work here. 🔗 External reference