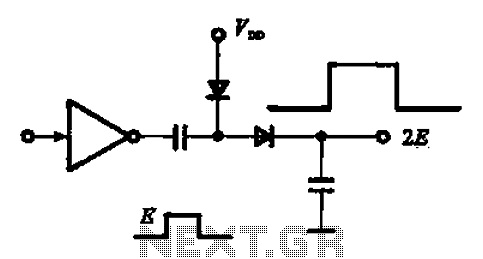

LED Brake/Rear Light Specifically for motorcycles Circuit diagram

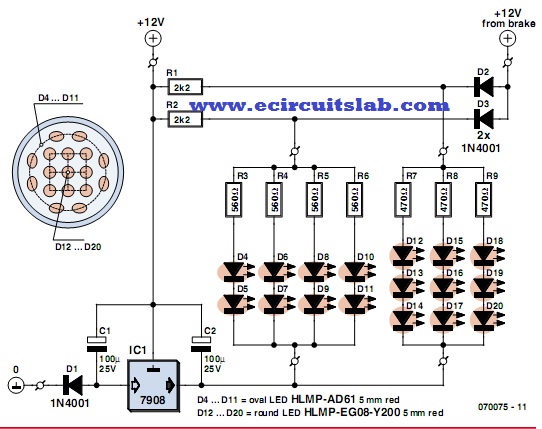

LEDs are increasingly utilized in motor vehicles, replacing traditional incandescent lamps due to their superior energy efficiency and extended lifespan. This article outlines a straightforward LED tail light specifically designed for motorcycles, scooters, and mopeds. There is a notable demand among motorcyclists for LED rear lights, as indicated by numerous discussions on this topic in various online forums. The circuits shared in these forums are often basic and lack robustness. Research into LED usage in motor vehicles reveals that the primary cause of LED failure is the improper or inadequate use of series resistors. In poorly designed circuits, multiple LEDs are frequently connected in parallel and powered by a single series resistor. Small variations among LEDs can lead to one LED failing, resulting in increased current through the remaining LEDs and potentially causing a cascading failure of the entire circuit. High-intensity LEDs exhibit significant variations in light output with minor current fluctuations, which must be considered during circuit design. This is particularly critical as engine RPM increases, leading to substantial voltage variations that can misrepresent braking signals when the throttle is opened. LEDs primarily require a constant current; thus, most circuits utilize a constant-current source for operation. The described circuit is designed to function as both a motorcycle rear light and a brake light, necessitating two different current levels. Given that the voltages measured on the author's motorcycle range from 10.5 to 15 V and that two distinct currents are needed for a total of 17 high-intensity LEDs, a single constant-current source is inadequate. The approach taken involves converting the highly variable DC voltage into a stable constant voltage, which is then converted into a constant current using multiple series resistors. A common issue discussed in forums is that the brake light signal is a positive voltage, which would require extensive modifications to the motorcycle. Consequently, the design incorporates a negative voltage regulator (7908) to regulate the voltage on the chassis side. This arrangement necessitates an additional chassis wire; typically, the negative side of the lamps is directly connected to the motorcycle chassis. However, this design allows both the positive connections for the rear light and the brake light to be directly linked to the LEDs. The lamp is composed of a central section featuring nine round red 5-mm LEDs (HLMP EG08 Y200) surrounded by eight oval red LEDs (HLMP AD61) of 5 mm. The round LEDs (D12 through D20), which have a narrow radiation angle, are arranged in series sets of three. Three of these strings are connected in parallel, with each string having its own series resistor. The oval LEDs (D4 to D11), which offer a wider radiation pattern, are connected in pairs, resulting in four parallel strings. Their wide radiation angle of 110 degrees ensures that the rear/brake light remains visible from the side. Both the oval and round strings are connected to the brake contact through diodes. When the brake is engaged, all LED strings receive +12V from the battery via the series resistors. Consequently, the light intensity is determined by the current flowing due to the series resistor and the voltage drop across the diodes. When the brake is not engaged, the LED strings remain connected to the battery's positive voltage, but this time through additional resistors to manage current flow effectively.

The schematic for this LED tail light circuit should include the following components: a power supply section capable of handling input voltages from 10.5V to 15V, a negative voltage regulator (7908) to stabilize the voltage at the chassis side, and multiple series resistors for current regulation. The LED configurations must be clearly depicted, showing the series and parallel arrangements of the round and oval LEDs, along with the necessary diodes for brake signal management. Each LED string should be labeled with its type and orientation to ensure correct assembly. The design should also incorporate protective features such as fuses or transient voltage suppressors to safeguard against voltage spikes, ensuring the longevity and reliability of the LED tail light system in a motorcycle environment.LEDs are used more and more in motor vehicles, replacing the standard incandescent lamps because they are more energy efficient and have a much longer life expectancy. In this article we describe a simple LED tail light that has been specifically designed for motorcycles, scooters and mopeds.

There appears to be a significant need among motorcycli sts for rear lights with LEDs, as evidenced by the many messages on this topic that turn up in various internet forums. The circuits that accompany these messages are often very rudimentary and therefore not very robust. After reading some of the literature concerning the use of LEDs in motor vehicles, it appears that the most common reason why LEDs still fail is the incorrect and/or insufficient use of series resistors.

In poorly implemented circuits there are often a number of LEDs connected in parallel which are all fed from a single series resistor. Because of small variations between LEDs, one LED can quickly give up the ghost. This causes an increase in current through the remaining LEDs and can easily lead to a domino effect, ultimately resulting in the failure of the entire circuit.

With high-intensity LEDs, a small variation in current is immediately obvious as a large variation in light output. This has to be taken into account when designing a circuit. This is important because when the engine rev speed goes up, the on-board voltage increases significantly.

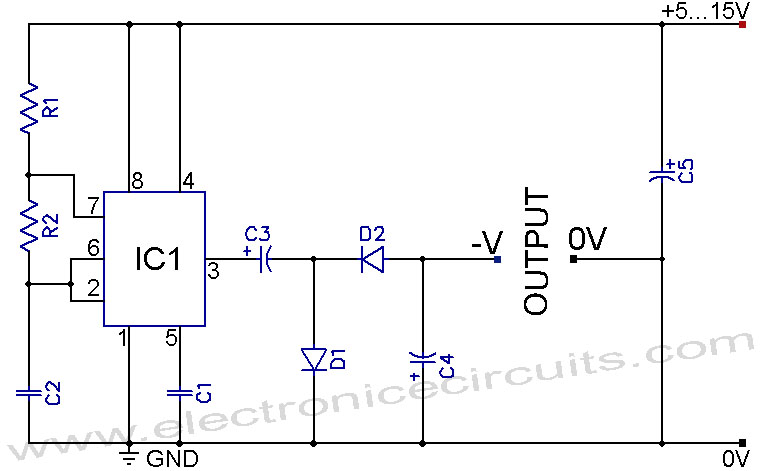

It would appear that you were braking when you actually opened the throttle instead. LEDs need mainly a constant current. That is why most circuits choose to drive LEDs from a constant-current source. This circuit has been designed to operate both as a motorcycle rear light and as a brake light. This requires two different currents. Because the voltages measured on the author`s motorcycle varied from 10. 5 to 15 V and because two different currents are required for the total of 17 high-intensity LEDs it was not possible to use only one constant-current source. The idea was to turn the strongly varying DC voltage into a nice constant voltage first and then turn that into a constant current through a number of series resistors.

The problem that is highlighted in many forums is the fact that the signal for the brake light is a positive voltage. It would require a lot of work on the motorcycle to change this. That is why the decision was made for a de sign that regulates the voltage on the chassis side, with the aid of a negative voltage regulator, a 7908.

The disadvantage of this arrangement is that an additional chassis wire is required; normally the minus side of the lamps is directly connected to the chassis of the motorcycle. However, the advantage is that both the + from the rear light as well as the + from the brake light can be directly connected to the LEDs.

The lamp` con sists of a centre part with nine round, red, 5-mm LEDs (HLMP EG08 Y200) wi th positioned around that eight oval, r e d L E D s HLMP AD61 of 5 mm. The round LEDs D12 through D20 which have qui te a narrow radi ation angle are connected in series in sets of 3.

Three of the se strings` are connected in parallel and each string has its own series resistor. The oval LEDs D4 to D11 which have a wide radiation pattern are connected with two in series, so there are therefore four strings connected in parallel. These ensure with their wide radiation angle of 110 degrees that the rear/brake-light is also clearly visible from the side.

The oval and round strings are connected to the brake contact via diodes. When the brake is operated all the strings are presented with the +12V from the battery via the series resistors. The light intensity therefore depends on the current that flows as a result of the series resistor (and the voltage drop across the diodes).

When the brake is not operated, the LEDs strings are still connected to the positive voltage of the battery, but this time via additional re 🔗 External reference

The schematic for this LED tail light circuit should include the following components: a power supply section capable of handling input voltages from 10.5V to 15V, a negative voltage regulator (7908) to stabilize the voltage at the chassis side, and multiple series resistors for current regulation. The LED configurations must be clearly depicted, showing the series and parallel arrangements of the round and oval LEDs, along with the necessary diodes for brake signal management. Each LED string should be labeled with its type and orientation to ensure correct assembly. The design should also incorporate protective features such as fuses or transient voltage suppressors to safeguard against voltage spikes, ensuring the longevity and reliability of the LED tail light system in a motorcycle environment.LEDs are used more and more in motor vehicles, replacing the standard incandescent lamps because they are more energy efficient and have a much longer life expectancy. In this article we describe a simple LED tail light that has been specifically designed for motorcycles, scooters and mopeds.

There appears to be a significant need among motorcycli sts for rear lights with LEDs, as evidenced by the many messages on this topic that turn up in various internet forums. The circuits that accompany these messages are often very rudimentary and therefore not very robust. After reading some of the literature concerning the use of LEDs in motor vehicles, it appears that the most common reason why LEDs still fail is the incorrect and/or insufficient use of series resistors.

In poorly implemented circuits there are often a number of LEDs connected in parallel which are all fed from a single series resistor. Because of small variations between LEDs, one LED can quickly give up the ghost. This causes an increase in current through the remaining LEDs and can easily lead to a domino effect, ultimately resulting in the failure of the entire circuit.

With high-intensity LEDs, a small variation in current is immediately obvious as a large variation in light output. This has to be taken into account when designing a circuit. This is important because when the engine rev speed goes up, the on-board voltage increases significantly.

It would appear that you were braking when you actually opened the throttle instead. LEDs need mainly a constant current. That is why most circuits choose to drive LEDs from a constant-current source. This circuit has been designed to operate both as a motorcycle rear light and as a brake light. This requires two different currents. Because the voltages measured on the author`s motorcycle varied from 10. 5 to 15 V and because two different currents are required for the total of 17 high-intensity LEDs it was not possible to use only one constant-current source. The idea was to turn the strongly varying DC voltage into a nice constant voltage first and then turn that into a constant current through a number of series resistors.

The problem that is highlighted in many forums is the fact that the signal for the brake light is a positive voltage. It would require a lot of work on the motorcycle to change this. That is why the decision was made for a de sign that regulates the voltage on the chassis side, with the aid of a negative voltage regulator, a 7908.

The disadvantage of this arrangement is that an additional chassis wire is required; normally the minus side of the lamps is directly connected to the chassis of the motorcycle. However, the advantage is that both the + from the rear light as well as the + from the brake light can be directly connected to the LEDs.

The lamp` con sists of a centre part with nine round, red, 5-mm LEDs (HLMP EG08 Y200) wi th positioned around that eight oval, r e d L E D s HLMP AD61 of 5 mm. The round LEDs D12 through D20 which have qui te a narrow radi ation angle are connected in series in sets of 3.

Three of the se strings` are connected in parallel and each string has its own series resistor. The oval LEDs D4 to D11 which have a wide radiation pattern are connected with two in series, so there are therefore four strings connected in parallel. These ensure with their wide radiation angle of 110 degrees that the rear/brake-light is also clearly visible from the side.

The oval and round strings are connected to the brake contact via diodes. When the brake is operated all the strings are presented with the +12V from the battery via the series resistors. The light intensity therefore depends on the current that flows as a result of the series resistor (and the voltage drop across the diodes).

When the brake is not operated, the LEDs strings are still connected to the positive voltage of the battery, but this time via additional re 🔗 External reference